I've been lurking in the wings on and off for a a while. Between your user name and your troubles with the Leyden, I had to sign on and share my view (I'd much rather be chasing trout!).

Last year I had an Arbor, the Avalon equivalent, installed to replace an existing Fisher. I've heated with wood on and off for 30 years counting running a couple different old Franklins growing up. I wanted to replace the Fisher so I could heat and watch the fire, get up to date, and have more control. My hearth is a "winged" brick floor and walls, all the way to the ceiling, with an 8" straight run up thru a two story house, probably 17' or so from the top of the stove. Above all else, I wanted control and simplicity.

My Arbor had a blower on it, and it helped a lot in cooling things down. I had the same experiences you are going thru right now. Small gas explosions, run-away conditions especially if I tried to load it up for the night, extremely hot (I did not have a flue probe) burning; basically conditions I didn't trust. I bought it due to be advertised as a non-catalytic, again trying to keep it simple. I didn't want to get into changing catalysts periodically.

I found the primary air control to be flimsy and not precise at all. Obviously these EPA cert stoves can't be shut down all the way, that's just the nature of the beast. But like you, when I shut it down as far as it would go, I would often still find myself sitting up late watching raging flames and rising temps, just hoping it would eventually settle down. One night, we had a "major" wood gas explosion that blew the lid open and slammed back shut. I was amazed the glass didn't break and ran outside to see if the chimney cap had been blown off. During normal operation with the combustor engaged, the bricks were hot to the touch, almost too hot to touch, since most of the real burning takes place in the back of the stove.

I had that stove for about 2 months of operation. The ratchet system for the bypass door stripped and wouldn't hold tight in that amount of time. The combustor cracked. I began to really evaluate what I had from a maintenance standpoint and started counting gaskets and also realized that the despite being called non-catalytic, that combustor was for all intents and purposes, a catalyst. It requires high temps to engage secondary combustion, burns at high temps behind the scenes, and when pressed, the Travis tech guy even admitted is a consumable that will need replacing after several years. As I recall, there is a gasket in the ash pan, 4 gaskets in the double doors if you count those between the frame and glass, a gasket on the top lid, and a miserable-to-replace gasket in the bypass door assembly. With the cracked combustor and stripped ratchet, Travis sent all the necessary parts to my dealer and they replaced everything under warranty. Could not have asked for anything more. But I did.

After my dissatisfaction, my dealer agreed to credit me full purchase price of the Arbor toward an Olympic which was very decent of him. The Arbor is a much nicer looking stove and I miss the top loading, but the Olympic is so much more simple. It will still get cranking and even run away if you're not right there to shut things down. But I'm learning that it will max out below the over firing level and really makes a lot of heat. I kept the blower, and with the design of this stove with a shroud around it, the bricks behind it never get beyond just warm to the touch. That's with or without the blower running. Granted its a completely different design being a top draft, but I have found the simplicity I was looking for and think it is a great stove. There are only two gaskets, the door to the firebox and the door to the glass. No ash pan, no bypass door, although there is a bypass slide control.

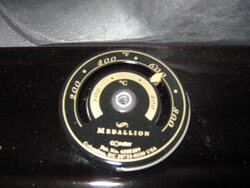

That's my story and with your similar experiences, I thought I would share. Not sure if my route is for you, but be warned - the Olympic is a heat throwing monster! I heat my entire 2 story house of 2700 sq ft with it. It is hard to keep it under 75 to 78 degrees if it is above 25 degrees outside. This weekend both mornings were around -10, cranked it up and let it cruise at 600 with the blower on high and brought the house up to 72 to 74 degrees within 90 minutes and kept it there no problems while it stayed in the single digits outside. I should also add that the Arbor smoked a lot less. Both are good, but the Olympic smokes more during the early stages of the burn cycle.

Brad