I currently have a Slant/Fin oil boiler installed in one side of my basement. It has 5 zones, one for indirect hot water tank, one for garage using baseboard, one for basement using cast iron rads, one for main level using cast iron rads and one for 2nd floor using baseboard. All components (except indirect water tank- Black iron pipe) are connected using 1/2" hepex plastic tubing.

I am planning on replacing my wood stove with an indoor conventional wood boiler, specicially Kerr TW2000. The wood boiler will be installed on the other side of the basement where the masonary chimney is located. The distance is about 47 feet from the exiting oil boiler. I'll obviously need a supply and return line running from the oil boiler to the wood boiler. The manual says that the supply/return lines cannot be plactic tubing. Is this correct? Do I need to use black iron piping to go that distance in the ceiling?

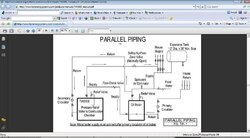

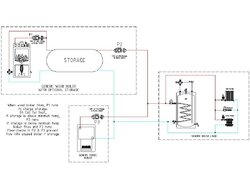

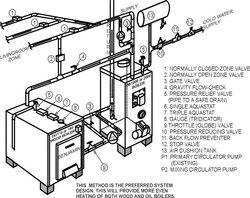

I'll post some pictures of the existing oil boiler and its setup, so I can get some help on where to connect the supply and return lines. I believe I will be going with a parallel setup as the attached diagram shows from the Kerr manual. The question is, can I use the existing circulator pump and expansion tank? or do I need to install addtional for the wood boiler?

I'll get pictures tonight and specs on my expansion tank and existing circulator pump.

I am planning on replacing my wood stove with an indoor conventional wood boiler, specicially Kerr TW2000. The wood boiler will be installed on the other side of the basement where the masonary chimney is located. The distance is about 47 feet from the exiting oil boiler. I'll obviously need a supply and return line running from the oil boiler to the wood boiler. The manual says that the supply/return lines cannot be plactic tubing. Is this correct? Do I need to use black iron piping to go that distance in the ceiling?

I'll post some pictures of the existing oil boiler and its setup, so I can get some help on where to connect the supply and return lines. I believe I will be going with a parallel setup as the attached diagram shows from the Kerr manual. The question is, can I use the existing circulator pump and expansion tank? or do I need to install addtional for the wood boiler?

I'll get pictures tonight and specs on my expansion tank and existing circulator pump.