My dealer installed the new pb105 pressure ignition system today in hopes that it will resolve the burnpot bubbles that I have had over the past two years. This ignition system is now being used on the new pf100 furnaces and pb105 boilers. In my mind, with the igniter not in the burnpot, the hot air for ignition is directed onto the pellets as they are fed into the burnpot, I don't see how a bubble on the surface of the burnpot could form now. The new ignition system sure does ignite the pellets quick.

UPDATE PB105 Pressure Ignition System Installed

- Thread starter wil lanfear

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

summit

Minister of Fire

stecy

Member

wil said:My dealer installed the new pb105 pressure ignition system today in hopes that it will resolve the burnpot bubbles that I have had over the past two years. This ignition system is now being used on the new pf100 furnaces and pb105 boilers. In my mind, with the igniter not in the burnpot, the hot air for ignition is directed onto the pellets as they are fed into the burnpot, I don't see how a bubble on the surface of the burnpot could form now. The new ignition system sure does ignite the pellets quick.

Wil

Could you clarify what exactly you mean by "burnpot bubbles"? Are you referring to carbon build-up? Or what?

Thanks,

Steve

The metal surface of the burnpot "humps up" from excessive heat being applied., above the igniter location.Steve Clay-Young said:wil said:My dealer installed the new pb105 pressure ignition system today in hopes that it will resolve the burnpot bubbles that I have had over the past two years. This ignition system is now being used on the new pf100 furnaces and pb105 boilers. In my mind, with the igniter not in the burnpot, the hot air for ignition is directed onto the pellets as they are fed into the burnpot, I don't see how a bubble on the surface of the burnpot could form now. The new ignition system sure does ignite the pellets quick.

Wil

Could you clarify what exactly you mean by "burnpot bubbles"? Are you referring to carbon build-up? Or what?

Thanks,

Steve

exoilburner

Feeling the Heat

My PF100 has had 2 new burn pots get the bump.

http://i357.photobucket.com/albums/oo18/eewing_01/BPotHoles2.jpg

http://i357.photobucket.com/albums/oo18/eewing_01/BPotHoles2.jpg

ex-oil slave

New Member

Hi Wil,

Can you give us a description of the new burnpot/igniter system that was installed for you? Does the new burnpot mount where the old one mounter without any modifications? Where is the igniter mounted now? Any modifications required for the new igniter location? How is it working so far? Did the dealer suggest this as a fix for the premature burnpot failures? Did Harman put out a bulletin to their dealers suggesting this as a fix? Who installed the mod - you or a dealer? How long did it take to install it? Your answers will be greatly appreciated. Thanks

Can you give us a description of the new burnpot/igniter system that was installed for you? Does the new burnpot mount where the old one mounter without any modifications? Where is the igniter mounted now? Any modifications required for the new igniter location? How is it working so far? Did the dealer suggest this as a fix for the premature burnpot failures? Did Harman put out a bulletin to their dealers suggesting this as a fix? Who installed the mod - you or a dealer? How long did it take to install it? Your answers will be greatly appreciated. Thanks

The Harman Co. had my dealer replace the ignition system in an effort to fix the burnpot bubble issue. First, let me mention that this new ignition system IS NOT a fix for the burnpot bubble issue, 4 weeks after it was installed a bubble started to form again. The new burnpot is the same part number, same burnpot, mounts the same place. My boiler is one of the older ones, the feeder mount had to be changed out with one with a coupling nut (igniter threads into it.) This was the first that my dealer had done, I worked with him to do the conversion, not hard to do at all, took around 3 hours.ex-oil slave said:Hi Wil,

Can you give us a description of the new burnpot/igniter system that was installed for you? Does the new burnpot mount where the old one mounter without any modifications? Where is the igniter mounted now? Any modifications required for the new igniter location? How is it working so far? Did the dealer suggest this as a fix for the premature burnpot failures? Did Harman put out a bulletin to their dealers suggesting this as a fix? Who installed the mod - you or a dealer? How long did it take to install it? Your answers will be greatly appreciated. Thanks

The ignition system consists of a air pump and a igniter that is a 1/2" tube with an electric element inside. The air pump pumps air past the electric element in this tube forcing this hot air against the pellets in the burnpot for ignition. It does ignite the pellets quickly.

ex-oil slave

New Member

In your initial post you said " I don’t see how a bubble on the surface of the burnpot could form now". Any ideas on how it's still bulging with the new ignition system? Maybe just the heat from burning pellets in the burnpot? With the forced air coming up thru the holes under a small pile of burning pellets it must have them glowing white hot right above where the air comes out. I wonder if the shape of the void under the burn plate is somehow focusing the air into that one area rather than having an even distribution of air coming up evenly thru all the holes. Maybe you could bounce that idea off your dealer and see what he can get from Harman since the "almighty manufacturer" won't deal with the common folk (aka, customers).

My dealer is aware, the Harman folks are aware that the burnpot issue has not been resolved. My dealer mentioned he will be at the factory I believe on 3/12 and will be chatting with Dan Harman about the issue. It just seems for some reason that a "hot spot" on the surface of the burnpot is causing these bubbles to form. The thought was that the igniter located in the burnpot restricted the air flow causing them to form above the igniter location, no igniter in my burnpot, bubble still forms in the same location. I recommend to all owners of the PB105's and PF100's that are having burnpot issue to go to the Harman website, take the survey, mentioning the burnpot issue to them, I did.ex-oil slave said:In your initial post you said " I don’t see how a bubble on the surface of the burnpot could form now". Any ideas on how it's still bulging with the new ignition system? Maybe just the heat from burning pellets in the burnpot? With the forced air coming up thru the holes under a small pile of burning pellets it must have them glowing white hot right above where the air comes out. I wonder if the shape of the void under the burn plate is somehow focusing the air into that one area rather than having an even distribution of air coming up evenly thru all the holes. Maybe you could bounce that idea off your dealer and see what he can get from Harman since the "almighty manufacturer" won't deal with the common folk (aka, customers).

ex-oil slave

New Member

Wil,

I went to Harman and filled out the survey. I made it clear that while I was happy with the overall product, I was very unhappy with their customer relations or more precisely their lack of the same. I mentioned the burnpot issue several times. When I finished the survey, I had to scroll top to bottom several times before I satisfied myself that, NO, there truly wasn't a place to enter an email address or phone number or name. Considering the fact that they gave you the opportunity to indicate you wouldn't buy their product again (which I did) and a space to give the reason why (which I did) I'm surprised they wouldn't want to be able to contact an unhappy customer. Must be nice to have so many customers it doesn't matter if you start losing them..... I will use my furnace until it dies or becomes too costly to maintain then I'll replace it with a model from a company that cares enough about their customers to at least provide an email or phone point of contact. I refuse to deal with a company that hides behind their dealers. If all dealers were knowledgeable, competent, and concerned it would be tolerable, but we all know that dealers are just people and people vary in their abilities and level of committment. If a customer gets stuck with a dealer that is incompetent or inconsiderate, they have no recourse.

Sorry for the rant, I'll stop now. I'm just frustrated that a business in this day and age is as consumer unfriendly as Harman is. Amazing.

I went to Harman and filled out the survey. I made it clear that while I was happy with the overall product, I was very unhappy with their customer relations or more precisely their lack of the same. I mentioned the burnpot issue several times. When I finished the survey, I had to scroll top to bottom several times before I satisfied myself that, NO, there truly wasn't a place to enter an email address or phone number or name. Considering the fact that they gave you the opportunity to indicate you wouldn't buy their product again (which I did) and a space to give the reason why (which I did) I'm surprised they wouldn't want to be able to contact an unhappy customer. Must be nice to have so many customers it doesn't matter if you start losing them..... I will use my furnace until it dies or becomes too costly to maintain then I'll replace it with a model from a company that cares enough about their customers to at least provide an email or phone point of contact. I refuse to deal with a company that hides behind their dealers. If all dealers were knowledgeable, competent, and concerned it would be tolerable, but we all know that dealers are just people and people vary in their abilities and level of committment. If a customer gets stuck with a dealer that is incompetent or inconsiderate, they have no recourse.

Sorry for the rant, I'll stop now. I'm just frustrated that a business in this day and age is as consumer unfriendly as Harman is. Amazing.

I mentioned to them that I was retired, had a lot of free time on my hands and I would be willing to test any parts they would suppy to resolve the burnpot issue. I even gave them my email address, my phone number, etc., haven't had any response as of today. Sad situation to say the least, when a company is aware of an issue and isn't willing to communicate. I did mention that maybe its time to replace my boiler, not all the boilers that were sold are having this burnpot issue.

exoilburner

Feeling the Heat

wil said:I recommend to all owners of the PB105's and PF100's that are having burnpot issue to go to the Harman website, take the survey, mentioning the burnpot issue to them, I did.

DONE. Complained about burn pot issue.

Wil, thanks for the suggestion. Didn't know about it.

stoveguy2esw

Minister of Fire

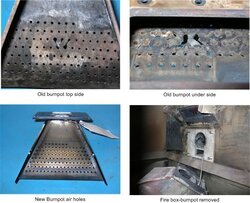

looking at the pictures of the "humped" burn pot grate , it appears the holes close to the "enlarged" holes are closed off or plugged up , not being familiar with this stove is that somthing that is done iontentionally or is it "just that way" from use, seems to me if those holes were open the heat wouldnt be as concentrated at the "hump" it may just be the angle of the picture also, so if they are clear my question wouldnt be of much use i guess

ex-oil slave

New Member

stoveguy.....

I can't talk about the burnpot in the picture as it isn't mine, but in my case, I kept the holes clean and clear and it made no difference. Since the igniter was removed from under the burn pot with the change in ignition system this thread started with, I think the igniter can be ruled out as the culprit. I'm thinking its due to the way the air flows into the void area under the burn pot floor. If the air flow is coming in and hitting the end of the void (where the cleanout door is located) and reflecting back into the air stream coming in, the two air streams would collide roughly under the area where the hump is forming. I think this area is getting a concentrated blast of air being directed up thru the holes due to the collision of these two air streams. This would cause the pellets above this area to burn hotter than those off to the side or lower/higher along the floor of the burn pot. This extra heat concentrated in one area could be causing what we are seeing.

I can't talk about the burnpot in the picture as it isn't mine, but in my case, I kept the holes clean and clear and it made no difference. Since the igniter was removed from under the burn pot with the change in ignition system this thread started with, I think the igniter can be ruled out as the culprit. I'm thinking its due to the way the air flows into the void area under the burn pot floor. If the air flow is coming in and hitting the end of the void (where the cleanout door is located) and reflecting back into the air stream coming in, the two air streams would collide roughly under the area where the hump is forming. I think this area is getting a concentrated blast of air being directed up thru the holes due to the collision of these two air streams. This would cause the pellets above this area to burn hotter than those off to the side or lower/higher along the floor of the burn pot. This extra heat concentrated in one area could be causing what we are seeing.

These photos (not mine) show better what a new burnpot looks like compared to the failure.stoveguy2esw said:looking at the pictures of the "humped" burn pot grate , it appears the holes close to the "enlarged" holes are closed off or plugged up , not being familiar with this stove is that somthing that is done iontentionally or is it "just that way" from use, seems to me if those holes were open the heat wouldnt be as concentrated at the "hump" it may just be the angle of the picture also, so if they are clear my question wouldnt be of much use i guess

Attachments

hoverfly

Minister of Fire

wil said:I mentioned to them that I was retired, had a lot of free time on my hands and I would be willing to test any parts they would suppy to resolve the burnpot issue. I even gave them my email address, my phone number, etc., haven't had any response as of today. Sad situation to say the least, when a company is aware of an issue and isn't willing to communicate. I did mention that maybe its time to replace my boiler, not all the boilers that were sold are having this burnpot issue.

Start calling them Toyota.........

exoilburner

Feeling the Heat

stoveguy2 said:looking at the pictures of the "humped" burn pot grate , it appears the holes close to the "enlarged" holes are closed off or plugged up , not being familiar with this stove is that somthing that is done iontentionally or is it "just that way" from use, seems to me if those holes were open the heat wouldnt be as concentrated at the "hump" it may just be the angle of the picture also, so if they are clear my question wouldnt be of much use i guess

stoveguy2,

The holes of the pictured burnpot were all checked for blockage once a week with a tool I made from a coat hangar. The picture does make it look like they are blocked but that was not the case. But I like your theory; it must be something like that.

Or, the metal of the burn pot needs to be more beefy. The holes in that thin plate must really reduce its strength. Add-in days of high heat and convection draft to that and its not a good scenario. But why is it only concentrated in that small area of the burn pot? Does minimum burn concentrate the heat in that area for extended periods of time???????? dunno.

- Status

- Not open for further replies.

Similar threads

- Replies

- 0

- Views

- 931

- Replies

- 15

- Views

- 1K

- Replies

- 16

- Views

- 2K

- Replies

- 2

- Views

- 549