I am planing on installing my new woodgun 180 and the manual says returning water cannot be under 160F. After reading through several old posts I came to the conclusion that a Danfoss Thermic By-pass Valve would be suitable. My local wholesaler gave me a spec sheet and it lists the 160F units as supply side and the 140F and 113F are for the return side. Can I just install what they call a supply side 160F unit and put it on my return side? Also my current piping has nothing larger than 1" but the new woodgun has 1.5" fittings, should I get a 1.25" or just a 1" valve. They are around $300.00 does that seem reasonable?

boiler return protection

- Thread starter mark123

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

ewdudley

Minister of Fire

mark123 said:I am planing on installing my new woodgun 180 and the manual says returning water cannot be under 160F. After reading through several old posts I came to the conclusion that a Danfoss Thermic By-pass Valve would be suitable. My local wholesaler gave me a spec sheet and it lists the 160F units as supply side and the 140F and 113F are for the return side. Can I just install what they call a supply side 160F unit and put it on my return side? Also my current piping has nothing larger than 1" but the new woodgun has 1.5" fittings, should I get a 1.25" or just a 1" valve. They are around $300.00 does that seem reasonable?

The housing is the same for any given pipe thread diameter, the only differences between the 160 and 140 versions is the thermostat inside the housing, and the fact that the 160 is normally plumbed in a diverting configuration and the 140 is normally plumbed in a mixing configuration. But you most certainly can plumb the 160 in a mixing configuration on the the return side.

$200 is more the going rate. Go ahead and get the 1.5", can't hurt although the smaller ones are less expensive. Here's a supplier on line, but the model number is probably not the 160 you need:

http://tinyurl.com/ygn6ekd

[The 1" pipe problem huskers raises below needs to be addressed. At 4 feet per second and 20F delta-T, 1" is only good for 100,000 btu / hour.]

i personnaly use a ranco control who got a temp. sensor installed on the return line.

the ranco shut off the main circ at 130f and start an other circ backward to keep the water running in a small loop to the boiler.

as my circ are grunfos 15-58 they have a check valve so the the water dont run backward thru the main pump

www.rancoetc.com

the ranco shut off the main circ at 130f and start an other circ backward to keep the water running in a small loop to the boiler.

as my circ are grunfos 15-58 they have a check valve so the the water dont run backward thru the main pump

www.rancoetc.com

Fred61

Minister of Fire

My 140 had two 1.5 inch return tappings. I built a 1.5 inch manifold of black iron in order to utilize both return pipes. Brought it down below the fan motor and teed it in the center. I felt it would be better for the boiler to even out the return water. I am assuming they are still building them that way.

As for return water temperature protection, I feel there is no simpler method than the danfoss valve. There should be no problem with the 160 in the return position.

As for return water temperature protection, I feel there is no simpler method than the danfoss valve. There should be no problem with the 160 in the return position.

I was wondering about the 2 reurn tappings, I called AHS and they said to just plug 1 but your idea seems better. Mine has a return near the bottom and another one about 2' up. So basically just T them together and have my danfoss on the T ?

Fred61

Minister of Fire

That's interesting! Mine had one on each side of the fan motor. Im not sure if the tee will do as much good with that configuration.

ewdudley

Minister of Fire

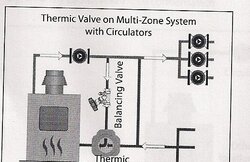

mark123 said:In this diagram, what is the balancing valve, what does it do compared to a ball valve? Also there is an extra by-pass to the right of it, why? I have 1 circ. pump and 5 zones. My circulating pump does not turn on unless a zone valve is open.

(This almost looks like a homework problem you're feeding us.)

You could use a ball valve as a balancing valve, but I believe I read somewhere that there can be an issue with wear on the ball itself with partially open ball valves, not that it would matter whatsoever in this application.

At any rate for the thermic valve to work properly it needs to see more or less equal resistance on both the hot and cold sides, so the balancing valve is used to adjust the hot side to be comparable resistance to the system return side.

The extra bypass on the right is bogus, it's just there to try to confuse you.

--ewd

So if I get the 1.5" thermic valve what size balancing valve should I get. What exactly is it called.

ewdudley

Minister of Fire

mark123 said:So if I get the 1.5" thermic valve what size balancing valve should I get. What exactly is it called.

Search back through threads dealing with this subject.

You could get fancy and use a Bell & Gosset circuit setter or some other purpose-built balancing valve, but I believe most guys use plain old ball valves, which should do the job perfectly.

Since you're going to be restricting flow substantially to achieve balance you could probably save a couple dozen dollars and use a 3/4" valve, but don't take my word for it.

Huskers asks above about your piping being 1" to begin with. Are you pumping into storage? Do you intend not to use so much of the boiler capacity?

in hot water

New Member

good, better, best balance valves. I think that is how B&G is advertizing their various balance valve options.how

For simple balancing with some "error" room a ball valve works fine. Most low end flow setting valves are ball type. Globe valves or flat disc are better, cone or tapered stem valves are best. It has to do with how well the valve can balance flow over a range of gpm changes, sometimes called valve authority.. A cone or tapered plug has e a very predictable range. Ball valves are hard to make precise adjustments with. not much happens until they are closed down then a tiny movement makes a big flow different. Systems with high flow velocity will after time wear that sharp edge of the ball away and the balance goes south.

This can be a deep subject with a lot of calculations involved

Robert Bean loves to talk about flow control, here is a link from his website. www.healthyheating.com/Page 55/Downloads/Control Valves.pdf

The flowsetter, any control valve really, should be sized by flow rate, not pipe size. A true flowsetter valve will have tables to help you with sizing. An off the shelf ball valve you will just need to play with to get the setting correct, for that application it may be accurate enough..

Many times just feeling the temperature with a strap on gauge or with bare hands is the method installers use. Ask the folks that created that drawing how to adjust the flow setting valve, it may be the touch and feel method they suggest

hr

For simple balancing with some "error" room a ball valve works fine. Most low end flow setting valves are ball type. Globe valves or flat disc are better, cone or tapered stem valves are best. It has to do with how well the valve can balance flow over a range of gpm changes, sometimes called valve authority.. A cone or tapered plug has e a very predictable range. Ball valves are hard to make precise adjustments with. not much happens until they are closed down then a tiny movement makes a big flow different. Systems with high flow velocity will after time wear that sharp edge of the ball away and the balance goes south.

This can be a deep subject with a lot of calculations involved

Robert Bean loves to talk about flow control, here is a link from his website. www.healthyheating.com/Page 55/Downloads/Control Valves.pdf

The flowsetter, any control valve really, should be sized by flow rate, not pipe size. A true flowsetter valve will have tables to help you with sizing. An off the shelf ball valve you will just need to play with to get the setting correct, for that application it may be accurate enough..

Many times just feeling the temperature with a strap on gauge or with bare hands is the method installers use. Ask the folks that created that drawing how to adjust the flow setting valve, it may be the touch and feel method they suggest

hr

Huskers, My current boiler has a 1.25" outlet and then it reduced to 1" for everything up to the zone valve manifold. I was planning on re-using all of this plumbing with the new woodgun. Although it is called the 180 the BTU output is rated at 150,??? My current boiler will put out 200000 BTU if the oil and wood are both going but I only used it as a wood boiler which is only 80000BTU.

Attachments

Woodrookie

New Member

Like many folks, I have been doing a lot of research in preperation of purchasing a unit before this winter sets in. I have been leaning towards a Wood Gun E180, but this thread gives me pause. I don't have a lot a mechanical skills and am not really able to do the kind of work your talking about here. I plan on having a professional do the installation, but once they're done the troubleshooting would be up to me. It sounds daunting to a lightwight like myself. Would I be in over my head if I go with a wood gun? Thanks, I appreciate any feedback.

If you are pumping to storage, 1-1/4" will probably be fine. With storage you have higher delta t and lower flow rates for the most part, so the slight increase in pressure drop across a 1-1/4" thermostatic valve to a 1-1/2" valve makes a negligible difference (if any at all) in performance. If you were actually going to use all 180,000 Btus of output you might want to go up to 1-1/2", but something tells me you won't actually be using all that output.

1-1/4" termovar valves run less than $200

cheers

1-1/4" termovar valves run less than $200

cheers

cheapsx

Member

Quick question, instead of a thermostatic mixing valve is anyone using a taco variable set point circulator for return protection? It appears as it can be set up for boiler return protection. Is it just to expensive to use? Looks like it could be set up so it would just do it's job and you wouldn't have to be setting a balancing valve.

http://www.taco-hvac.com/en/products/Variable Speed Setpoint "00"<sup>®</sup> Circulator/products.html?current_category=193

http://www.taco-hvac.com/en/products/Variable Speed Setpoint "00"<sup>®</sup> Circulator/products.html?current_category=193

- Status

- Not open for further replies.

Similar threads

- Replies

- 9

- Views

- 2K

- Replies

- 4

- Views

- 787

- Replies

- 5

- Views

- 2K

- Replies

- 1

- Views

- 996