All non condensing boilers need return temperature protection. The boiler AND the flue piping needs to get above the condensing mode to prevent deterioation of the heat exchanger and flue piping. Even thick cast iron can be ruined in a years time if the return is not watched and compensated for.

The question is how long is too long. Many boilers start from a cold condition, maybe even room temperature. Most in the industry would like to see the boiler warmed within 10 minutes, same for the flue piping. No more than 15 minutes in my opinoin. Also avoid short cycles where the boiler runs down to below and "sweats" often.

The provide adequate protection you really need a device that can sense temperature and react accordingly. A bypass pipe and valve will not provide this. A bypass pump alone will not.

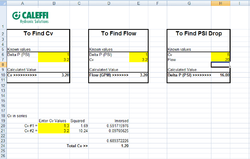

Three way thermostatic are one common choice. You need to look at the spec sheet to properly size one. Valves have a Cv rating, simply the amount of gpm you can flow through the valve with an industry recommended 1 psi pressure drop. Most 3 ways have a 3 Cv, high flow 5 Cv.

Now you can flow more than 5 gpm through a valve, but the pressure drop, or resistence to flow goes up with increased flow. excessive flow can cause wear, and noise problems. We put together an Excel sheet to show how this relationship works. In this example a 5 Cv valve flowing 20 gpm (moving 200,000 BTU/hr perhaps) has a pressure drop of 16 psi. So you can see how pump size jumps up considerable. really thermostatics were designed for DHW applications, not really continous flow at high gpm rates. better brands have larger volutes and cartridges to allow more flow. Large flow thermostatic valves get pretty $$.

Also watch the other numbers on the specs. The pressure ratio for example 2:1 from hot to cold side for the valve to be able to track properly. Putting pumps in the wrong location or in and out of series can effect the ability of the valve to track properly. Also multiple expansion tank connections have an effect on the pressure the valve sees as pumps start and stop. This is where balance valve come into play. Also the cold water spec and the min. temperature difference figure. To allow the valve to track accurately all those numbers need to be addresses.

I still feel a circ with either an on/off aquastat or variable speed function provide the best, lowest energy consumption and most accureate method of return protection, just depends on what the trade offs are, every job is different.

hr

!

!