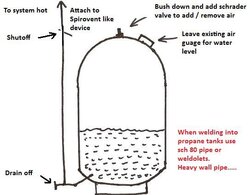

I have been trying hard to find a 500 gallon propane tank. Luck would have it... I brought my kid to his friends house.. .and lo and behold... they had swapped out their tanks and the company had left a 250 gallon tank behind. They said it was not their company. I checked the date on said tank. It is a 1993 and was still holding propane. I brought it home and opened the valve. It is empty now. So....... what do I do now? I was really hoping for at least 500 gallons. I guess I am going to wait until I can find another 250 or 500 gallon one. Then hook them up together... giveing me either 500 or 750 total.

Should I at least get started cleaning this one? What do I do now?

And of course my last question... does anyone know where I can get a 500 gallon one? I tried craigslist for New England area. No luck yet.

I ask every person I come in contact with... and if they know anyone who may have one. My wife thinks I am a freak... or possessed by Hearth.com demons.

I also drive around in search of one... .looking everywhere I can .

Should I at least get started cleaning this one? What do I do now?

And of course my last question... does anyone know where I can get a 500 gallon one? I tried craigslist for New England area. No luck yet.

I ask every person I come in contact with... and if they know anyone who may have one. My wife thinks I am a freak... or possessed by Hearth.com demons.

I also drive around in search of one... .looking everywhere I can .