[quote author="sparke" date="1277231691"]

...

How big of an expansion tank do I need?

[/quote]

Here's some tables for a charged expansion tank.

There are three tables for three different maximum system design pressures, p_hi=20psig, p_hi=25psig, and p_hi=30psig. If your maximum system design pressure is in between those given then a simple interpolation should get you pretty close.

A charged expansion tank is either a diaphragm tank or a closed expansion tank that is charged with air pressure to the minimum system static pressure at the elevation of the the expansion tank.

Expansion tank volume is given as a percent of system volume, so if the table reads 6.9 and the system is 1100 gallons, then minimum tank size would be about 76 gallons.

These are minimum volumes according to Boyle's Law and the properties of water. The tank is assumed to be perfectly charged (no amount of flooding and no excess air charge).

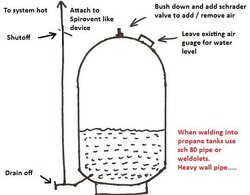

[Edit: Near-perfect charging is easy enough with a membrane tank, but maintaining near-perfect charging with a simple closed expansion tank may require more attention. Therefore an over-sized tank would be preferable when considering a simple non-membrane closed expansion tank, e.g., a converted propane tank.

Have since found a good resource on the topic of expansion tanks (But keep in mind that they are trying to sell membrane tanks.):

http://www.amtrol.com/enginhandbook.htm ]

Also changes in the temperature of the air inside the expansion tank are ignored.

...

How big of an expansion tank do I need?

[/quote]

Here's some tables for a charged expansion tank.

There are three tables for three different maximum system design pressures, p_hi=20psig, p_hi=25psig, and p_hi=30psig. If your maximum system design pressure is in between those given then a simple interpolation should get you pretty close.

A charged expansion tank is either a diaphragm tank or a closed expansion tank that is charged with air pressure to the minimum system static pressure at the elevation of the the expansion tank.

Expansion tank volume is given as a percent of system volume, so if the table reads 6.9 and the system is 1100 gallons, then minimum tank size would be about 76 gallons.

These are minimum volumes according to Boyle's Law and the properties of water. The tank is assumed to be perfectly charged (no amount of flooding and no excess air charge).

[Edit: Near-perfect charging is easy enough with a membrane tank, but maintaining near-perfect charging with a simple closed expansion tank may require more attention. Therefore an over-sized tank would be preferable when considering a simple non-membrane closed expansion tank, e.g., a converted propane tank.

Have since found a good resource on the topic of expansion tanks (But keep in mind that they are trying to sell membrane tanks.):

http://www.amtrol.com/enginhandbook.htm ]

Also changes in the temperature of the air inside the expansion tank are ignored.

Code:

Expansion tank size as percent of system water volume.

Low temperature set to 50F, which is close to maximum density.

'p_lo' is minimum static pressure at the expansion tank when

system temperature is at a nominal 50F. Elevating expansion tank

will lower its minimum static pressure.

(Pressures psig, temperatures degF.)

t_lo=50 p_hi=20:

t_hi

p_lo 160 170 180 190 200 210

2 4.57 5.17 5.90 6.62 7.46 8.18

3 4.84 5.48 6.24 7.01 7.90 8.66

4 5.14 5.82 6.63 7.44 8.39 9.20

5 5.49 6.21 7.07 7.94 8.95 9.82

6 5.88 6.65 7.58 8.51 9.59 10.52

7 6.33 7.16 8.16 9.16 10.33 11.33

8 6.86 7.76 8.84 9.93 11.19 12.27

9 7.48 8.47 9.65 10.83 12.21 13.39

10 8.23 9.31 10.61 11.91 13.43 14.73

11 9.14 10.35 11.79 13.24 14.92 16.36

12 10.29 11.64 13.27 14.89 16.78 18.41

13 11.76 13.30 15.16 17.02 19.18 21.04

14 13.72 15.52 17.69 19.85 22.38 24.55

15 16.46 18.63 21.22 23.82 26.86 29.45

t_lo=50 p_hi=25:

t_hi

p_lo 160 170 180 190 200 210

2 4.09 4.63 5.28 5.93 6.68 7.33

3 4.28 4.84 5.52 6.19 6.98 7.66

4 4.48 5.07 5.78 6.49 7.32 8.02

5 4.71 5.33 6.07 6.81 7.68 8.42

6 4.96 5.61 6.39 7.17 8.09 8.87

7 5.23 5.92 6.75 7.57 8.53 9.36

8 5.54 6.27 7.14 8.02 9.04 9.91

9 5.89 6.66 7.59 8.52 9.60 10.53

10 6.28 7.10 8.09 9.09 10.24 11.23

11 6.73 7.61 8.67 9.73 10.97 12.04

12 7.24 8.20 9.34 10.48 11.82 12.96

13 7.85 8.88 10.12 11.36 12.80 14.04

14 8.56 9.69 11.04 12.39 13.97 15.32

15 9.42 10.65 12.14 13.63 15.36 16.85

16 10.46 11.84 13.49 15.14 17.07 18.72

17 11.77 13.32 15.18 17.04 19.20 21.06

18 13.45 15.22 17.35 19.47 21.95 24.07

19 15.69 17.76 20.24 22.71 25.60 28.08

20 18.83 21.31 24.28 27.26 30.73 33.70

t_lo=50 p_hi=30:

t_hi

p_lo 160 170 180 190 200 210

2 3.79 4.28 4.88 5.48 6.18 6.78

3 3.93 4.44 5.06 5.68 6.41 7.03

4 4.08 4.61 5.26 5.90 6.65 7.30

5 4.24 4.80 5.47 6.14 6.92 7.59

6 4.42 5.00 5.70 6.39 7.21 7.91

7 4.61 5.22 5.94 6.67 7.52 8.25

8 4.82 5.45 6.21 6.98 7.86 8.62

9 5.05 5.71 6.51 7.31 8.24 9.03

10 5.30 6.00 6.84 7.67 8.65 9.49

11 5.58 6.31 7.20 8.08 9.10 9.99

12 5.89 6.67 7.60 8.53 9.61 10.54

13 6.24 7.06 8.04 9.03 10.18 11.16

14 6.63 7.50 8.54 9.59 10.81 11.86

15 7.07 8.00 9.11 10.23 11.53 12.65

16 7.57 8.57 9.77 10.96 12.36 13.55

17 8.16 9.23 10.52 11.80 13.31 14.59

18 8.84 10.00 11.39 12.79 14.42 15.81

19 9.64 10.91 12.43 13.95 15.73 17.25

20 10.60 12.00 13.67 15.35 17.30 18.97

21 11.78 13.33 15.19 17.05 19.22 21.08

22 13.25 15.00 17.09 19.18 21.62 23.72

23 15.15 17.14 19.53 21.92 24.71 27.10

24 17.67 20.00 22.79 25.58 28.83 31.62

25 21.20 23.99 27.34 30.69 34.60 37.94