- Feb 11, 2010

- 149

First of all, I plan on finding a foam contractor and having my lines foamed in the ground. In a recent similar thread, someone mentioned running their underground PEX inside of black drain pipe and then foaming that in place just in case they needed to ever replace the lines, add more, or to ensure there will be 0 water infiltration if the closed cell foam ever does get waterlogged. I thought that was a great idea, but realized it would make more sense to run separate drain lines to run the PEX inside so you're not transferring heat between your supply and return lines if they are run together.

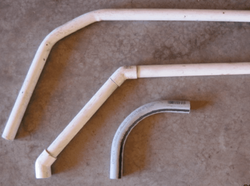

So I just did a little pricing of parts. My trench is going to be about 100' long. 250' of 4" drain tile is about $100. Foaming 4x8" of tile into the ground with 2-3" all around it would use quite a bit of foam and require one heck of a trench too. But, 10' sections of 2" plastic electrical conduit is a little less than $4 each. For 200' (supply and return) of that is about $80. I can seal 10' sections of the conduit with PVC glue to keep them watertight, although it really isn't necessary since the foam should keep the water out 100%. 2x4" of piping to foam 2-3" over requires a lot less foam as well. Plus, should I ever have the need to replace the PEX, the electrical conduit will be much more slippery than the drain tile for sliding 100' of tubing through. Although the electrical conduit is "rigid," it will still be fairly flexible. Another great plus is that I plan on pouring my concrete pad today and to get the lines from underground and up through the pad, I was already planning on using the large electrical conduit elbows because of their large radius curve which will make a nice gentle turn for the PEX. I'm going to do 2 2" elbows for the PEX and 2 1" elbows for electrical and control wires. I might add a couple elbows with nothing to go through them just in case I ever need to use them.

So here's my question:

I'm going to be using 1-1/4" PEX. I realize that size is pretty much the OD of the PEX. will 1-1/4" PEX slip through 2" conduit OK? I don't know what the ID of 2" conduit actually is.

So I just did a little pricing of parts. My trench is going to be about 100' long. 250' of 4" drain tile is about $100. Foaming 4x8" of tile into the ground with 2-3" all around it would use quite a bit of foam and require one heck of a trench too. But, 10' sections of 2" plastic electrical conduit is a little less than $4 each. For 200' (supply and return) of that is about $80. I can seal 10' sections of the conduit with PVC glue to keep them watertight, although it really isn't necessary since the foam should keep the water out 100%. 2x4" of piping to foam 2-3" over requires a lot less foam as well. Plus, should I ever have the need to replace the PEX, the electrical conduit will be much more slippery than the drain tile for sliding 100' of tubing through. Although the electrical conduit is "rigid," it will still be fairly flexible. Another great plus is that I plan on pouring my concrete pad today and to get the lines from underground and up through the pad, I was already planning on using the large electrical conduit elbows because of their large radius curve which will make a nice gentle turn for the PEX. I'm going to do 2 2" elbows for the PEX and 2 1" elbows for electrical and control wires. I might add a couple elbows with nothing to go through them just in case I ever need to use them.

So here's my question:

I'm going to be using 1-1/4" PEX. I realize that size is pretty much the OD of the PEX. will 1-1/4" PEX slip through 2" conduit OK? I don't know what the ID of 2" conduit actually is.