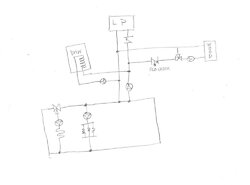

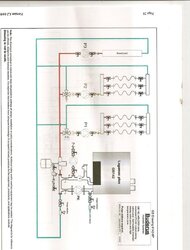

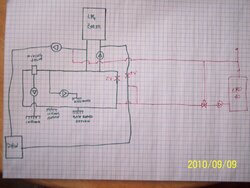

I want to tie in my eko 40 to the existing system which is the green colour. The red color is what id like to do if it will work. Id like to have it wired so that when the eko is running the lpg boiler shuts off and the two zone valves close so that I dont get flow through the lpg boiler.

I Am not sure if the left zv is needed or not.

I have tested the system with lpg boiler shut off and everything is still operational except the p/p below the lpg boiler

Cheers Huff

I Am not sure if the left zv is needed or not.

I have tested the system with lpg boiler shut off and everything is still operational except the p/p below the lpg boiler

Cheers Huff

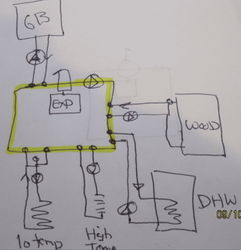

The GB is tied into the inner loop via P/S. The EKO is parallel to the DHW loop. The DHW loop is parallel to the GB.

The GB is tied into the inner loop via P/S. The EKO is parallel to the DHW loop. The DHW loop is parallel to the GB.