Plan or ripping up 12x14 bedroom floor rug and replacing it with Pergo style floor. Would like to put radiant floor down. Considering ripping up 1st layer(5/8?) of subfloor and putting in a warmboard type flooring. Looking for warmboard or it's =. Any sugesstions?

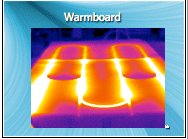

I can install staple up underneath floor, which i have in kitchen. But would like to experiment with a Warmboard type of product. Would like to have the radiant close to living space as possible. I know it's got possibilities of being a PITA ripping up subfloor.

Any thoughts on this project and type of materials to use?

I can install staple up underneath floor, which i have in kitchen. But would like to experiment with a Warmboard type of product. Would like to have the radiant close to living space as possible. I know it's got possibilities of being a PITA ripping up subfloor.

Any thoughts on this project and type of materials to use?