Econoburn is recommending using a mixing valve to protect the boiler in addition to the bypass circulator. Why not just eliminate the bypass circulator and set up like a Tarm? Has anyone set their boiler inthis manner?

Why a bypass circulator and Mixing Valve for Econoburn?

- Thread starter heat4steve

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

twitch

Member

I think I know what you're talking about, but can you post a simple diagram? sketch it on paper, take a photo, and upload it. There may be a reason, just not sure. Have you asked them the question?

kabbott

Member

Piker said:cannot imagine a reason to have both.

cheers

+1

I use a variable speed bypass pump on my Varmebaronen and it works great, I see no reason for both.

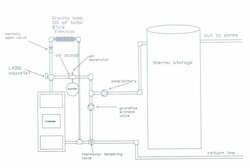

Thanks for the interest. For some more information, the econoburn control runs the the bypass circulator until the aquastat reaches 150. After that this pump is shutoff and then the primary circulator is enabled. The installation manual calls for the mixing valve to protect the boiler from cold water slugs which entering the boiler and causing thermal shock. However, it seems the mixing valve with a single (primary) circulator should be adequate. The recommended near boiler plumbing seems unecssarily complex. I am thinking of trying to eliminate the bypass pump. The recommended piping configuration provided from econoburn is shown below:

Attachments

kabbott

Member

I suppose that explains the reason for both the pump and the mixing valve. It seems the bypass pump only runs at start-up, My bypass pump will run any time the return temp

drops. I am not sure but the bypass pump may be to eliminate "hot spots" in the boiler until the primary pump comes on.

I start my bypass pump when the stack temp rises above 200 degrees and then it varies depending on return temps. My main pump starts when the boiler reaches 160.

drops. I am not sure but the bypass pump may be to eliminate "hot spots" in the boiler until the primary pump comes on.

I start my bypass pump when the stack temp rises above 200 degrees and then it varies depending on return temps. My main pump starts when the boiler reaches 160.

goosegunner

Minister of Fire

I just talked to Mark at Econoburn today. I had the same question. He said if you are setting up with storage to use a mixing valve and you did not need the pump they included. He said pump can be used elsewhere in your system but is included for people not using storage.

I didn't get that drawing from econoburn that you posted. Seems odd to return water to boiler only and not storage. Wouldn't that cool boiler down to storage temp if fire is not going?

gg

I didn't get that drawing from econoburn that you posted. Seems odd to return water to boiler only and not storage. Wouldn't that cool boiler down to storage temp if fire is not going?

gg

That is just a terrible design for piping to storage...

cold return water from the zones actually gets put back into the top of the storage tank, screwing up stratification. Yikes. And there is absolutely no need for the near boiler circulator when using the termovar.

The bypass circulator control is intended to do the same thing as a termovar... to temper return water by circulating out of the boiler and right back into the boiler below 150... but because of where they place (or at least used to place the thermocouple) cold water can shock the back of the boiler for several minutes before a temperature change is registered. The termovar offers a much smoother operation, and true return water protection...

cheers

cold return water from the zones actually gets put back into the top of the storage tank, screwing up stratification. Yikes. And there is absolutely no need for the near boiler circulator when using the termovar.

The bypass circulator control is intended to do the same thing as a termovar... to temper return water by circulating out of the boiler and right back into the boiler below 150... but because of where they place (or at least used to place the thermocouple) cold water can shock the back of the boiler for several minutes before a temperature change is registered. The termovar offers a much smoother operation, and true return water protection...

cheers

Based on the description of the Econoburn controls, the bypass circulator operates until the aquastat reaches a setpoint of 150. If the bypass circulator is removed the controls need to be change to only use the primary circulator. I am sure this can be done - did Mark tell you how this can be done? As you are probably aware these mixing valves can be expensive - especially for the pipe sizes of 1-1/2" so I want to make sure I don't buy a valve unecessarily.goosegunner said:I just talked to Mark at Econoburn today. I had the same question. He said if you are setting up with storage to use a mixing valve and you did not need the pump they included. He said pump can be used elsewhere in your system but is included for people not using storage.

I didn't get that drawing from econoburn that you posted. Seems odd to return water to boiler only and not storage. Wouldn't that cool boiler down to storage temp if fire is not going?

gg

Concerning the diagram, this one of two schematics Dale at econoburn provided - the other without storage. For this mechanization, you are correcct, the boiler will cooldown with the thermal storage temperature. In addition, it is not setup for reverse flow in the case where youre tanks are thermaly stratified.

wood thing

Member

I did not get that drawing, in fact I did not get much of anything. Seems like its trail & error at our expense. They are nice people to talk with but frankly I have had more input from this forum. I installed my ecconoburn in March this year and fired all summer. I have done several rebuilds and changes. Thank goodness I do my own work. I think I finaly got it. I will follow this thread to see how you make out.

in hot water

New Member

Consider using pumps with variable speed control. This is maybe the most efficient and most accurate way to mix and provide return protection. Three way mixing valves or devices are parasitic devices. They use some, maybe a lot, depending on the Cv rating, of the circ energy to overcome the resistance thru then.

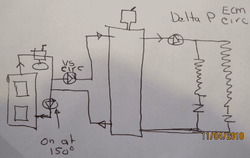

By using circs, better yet ECM type circs you move the energy with the least amount of electrical energy consumption and leverage the accuracy of a thermistor instead of a wax cartridge for temperature modulation.

Yes, this may be a bit more $$ on the front end but the energy savings over the next 20 years coupled with the control-ability make this an attractive option.

I have my EKO connected to 500 gallons piped and controlled this way. I used the least expensive solar controller with a VS and thermostatic function to drive this and it included some basic data logging as well as digital readout, hour meter, etc as part of the control.

hr

By using circs, better yet ECM type circs you move the energy with the least amount of electrical energy consumption and leverage the accuracy of a thermistor instead of a wax cartridge for temperature modulation.

Yes, this may be a bit more $$ on the front end but the energy savings over the next 20 years coupled with the control-ability make this an attractive option.

I have my EKO connected to 500 gallons piped and controlled this way. I used the least expensive solar controller with a VS and thermostatic function to drive this and it included some basic data logging as well as digital readout, hour meter, etc as part of the control.

hr

Attachments

I just ran the calculation for a Danfoss mixinvg valve with a CV of 20. The head loss at 13 lpm is over 5ft. This is quite high considering the head loss in the piping is 2ft for this flow. Your recommendation makes sense. I was looking at a variable speed pump for the house zones but the economics did not make sense to justify. However if I can eliminate a $100-200 valve it likely will. I will consider your ides. Thank you.in hot water said:Consider using pumps with variable speed control. This is maybe the most efficient and most accurate way to mix and provide return protection. Three way mixing valves or devices are parasitic devices. They use some, maybe a lot, depending on the Cv rating, of the circ energy to overcome the resistance thru then.

By using circs, better yet ECM type circs you move the energy with the least amount of electrical energy consumption and leverage the accuracy of a thermistor instead of a wax cartridge for temperature modulation.

Yes, this may be a bit more $$ on the front end but the energy savings over the next 20 years coupled with the control-ability make this an attractive option.

I have my EKO connected to 500 gallons piped and controlled this way. I used the least expensive solar controller with a VS and thermostatic function to drive this and it included some basic data logging as well as digital readout, hour meter, etc as part of the control.

hr

in hot water

New Member

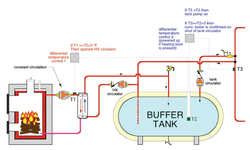

If a system uses an un-pressurized boiler, or an un-pressurized storage then a HX could be introduced. This could be a coil in a tank like Tom builds, or the plate type shown here.

So the vs function could double as the return protection and the energy transfer. A solar controller with 2 outputs could run both circ shown here and perhaps fire the auxiliary heat source.

I think you will see the cost of ECM circ dropping. ITT has acquired Laing Pump of Germany. I suspect they will release an ECM circ without the delta T or P function at a lower cost than the brands currently available.

*schematic credit Appropriate Design used with permission

hr

So the vs function could double as the return protection and the energy transfer. A solar controller with 2 outputs could run both circ shown here and perhaps fire the auxiliary heat source.

I think you will see the cost of ECM circ dropping. ITT has acquired Laing Pump of Germany. I suspect they will release an ECM circ without the delta T or P function at a lower cost than the brands currently available.

*schematic credit Appropriate Design used with permission

hr

Attachments

mwk1000

Member

That looks very close to my setup. Except my "Tank Circulator" draws directly from th HX Input where it is a T. That way when the tank is cold and you are firing up it will take the flow directly from (driven by) the HX Circulator that is HOT strait to the zones. When the HX cirulator is off the Head is higher through the HX/Pump so the zones are fed strait from the tank. Seems to be working well , the house heat load will be satisfied first then the tank no extra valves or pumps or tank ports just a T.

I like this approach. Did you have to modify the EKO controls to make this work or do the controls only shut the pump on and off? The Econoburn controls the bypass circulator and primary circulator sequentially using relay - I think I could rewire the relay to control just the primary ciruclator to work all the time. If so this option your configuration could work for me.in hot water said:Consider using pumps with variable speed control. This is maybe the most efficient and most accurate way to mix and provide return protection. Three way mixing valves or devices are parasitic devices. They use some, maybe a lot, depending on the Cv rating, of the circ energy to overcome the resistance thru then.

By using circs, better yet ECM type circs you move the energy with the least amount of electrical energy consumption and leverage the accuracy of a thermistor instead of a wax cartridge for temperature modulation.

Yes, this may be a bit more $$ on the front end but the energy savings over the next 20 years coupled with the control-ability make this an attractive option.

I have my EKO connected to 500 gallons piped and controlled this way. I used the least expensive solar controller with a VS and thermostatic function to drive this and it included some basic data logging as well as digital readout, hour meter, etc as part of the control.

hr

wood thing said:I did not get that drawing, in fact I did not get much of anything. Seems like its trail & error at our expense. They are nice people to talk with but frankly I have had more input from this forum. I installed my ecconoburn in March this year and fired all summer. I have done several rebuilds and changes. Thank goodness I do my own work. I think I finaly got it. I will follow this thread to see how you make out.

Dale and his son Mark have always been willing to help and promptly return calls. Definitely the technical information could be better and the installation manual provides limited information. It is diffult to size the the pump and piping without knowing the boiler head - I am asuming it is rather small (less than 2ft at 12gpm). Would you mind sharing how you setup bypass loop?

in hot water

New Member

My EKO arrived with a simple 150 °F snap disc control mounted on the top of the firebox. It does look like something the dealer may have added, not factory. It is very effective and has worked well for going on 5 seasons now. It basically starts the boiler circ when the temperature rises to 150 and turns off at around 138- 140 °F.

It's about a $12 switch, maybe consider it a poor-mans return temperature protection device. I have seen this same concept used on high end Viessmann gas fired boilers with a well type aquastat. The beauty is the simplicity of the control and the ability to provide return temperature protection without a more expensive device, and piping like a 3 way or 3 way pump device requires.

So that frees up some money to but a nice control for the next functions. Solar differential controllers are ideal for shuffling to a buffer or bypassing the buffer and going directly to the load first. The variable speed function gives you a second level of boiler protection and helps keep the boiler firing in it's sweet spot. It regulates the rate of heat exchange almost perfectly. Consider it a cruise control for your boiler.

All this can be accomplished with off the shelf, or off e-bay , circs. This allows you to match the circulators to the load, 3 speed circs enhance the adjustability on the fixed speed circs.

, circs. This allows you to match the circulators to the load, 3 speed circs enhance the adjustability on the fixed speed circs.

hr

It's about a $12 switch, maybe consider it a poor-mans return temperature protection device. I have seen this same concept used on high end Viessmann gas fired boilers with a well type aquastat. The beauty is the simplicity of the control and the ability to provide return temperature protection without a more expensive device, and piping like a 3 way or 3 way pump device requires.

So that frees up some money to but a nice control for the next functions. Solar differential controllers are ideal for shuffling to a buffer or bypassing the buffer and going directly to the load first. The variable speed function gives you a second level of boiler protection and helps keep the boiler firing in it's sweet spot. It regulates the rate of heat exchange almost perfectly. Consider it a cruise control for your boiler.

All this can be accomplished with off the shelf, or off e-bay

, circs. This allows you to match the circulators to the load, 3 speed circs enhance the adjustability on the fixed speed circs.

, circs. This allows you to match the circulators to the load, 3 speed circs enhance the adjustability on the fixed speed circs.hr

heat4steve said:Based on the description of the Econoburn controls, the bypass circulator operates until the aquastat reaches a setpoint of 150. If the bypass circulator is removed the controls need to be change to only use the primary circulator. I am sure this can be done - did Mark tell you how this can be done? As you are probably aware these mixing valves can be expensive - especially for the pipe sizes of 1-1/2" so I want to make sure I don't buy a valve unecessarily.goosegunner said:I just talked to Mark at Econoburn today. I had the same question. He said if you are setting up with storage to use a mixing valve and you did not need the pump they included. He said pump can be used elsewhere in your system but is included for people not using storage.

I didn't get that drawing from econoburn that you posted. Seems odd to return water to boiler only and not storage. Wouldn't that cool boiler down to storage temp if fire is not going?

gg

Concerning the diagram, this one of two schematics Dale at econoburn provided - the other without storage. For this mechanization, you are correcct, the boiler will cooldown with the thermal storage temperature. In addition, it is not setup for reverse flow in the case where youre tanks are thermaly stratified.

No one should use that drawing... it's just wrong for thermal storage. That's not even a good way to pipe a large buffer tank.

To be honest, I don't think you really even need circulation through the boiler below 150... water will move throughout the vessel via convection until the vessel hits 150 and the circulator turns on. This is how some of the european gasifiers operate, including the Froling FHG. I would not set up an econoburn like that, however, unless they provided a written addendum to your warranty that approves the design.

According to what the Tech team at Tarm says, the pressure drop across an 1 1/4" termovar mixing valve is negligible, so plumbing an 1 1/4" valve into an 1 1/2" system will be fine. You also have to consider, that your storage will be running a pretty good sized delta T most of the time... you might be sending 165 or 170° water to the top of the tank and returning 110 or 120... with that kind of a delta T, you don't need much flow anyways. Actually, the termovar loading units that we use on even the big solo plus boilers (200,000 Btu) just use a little 15-58 grundfos. You might only get 10 or 12 gpm to a closed loop storage tank... but that's all you need.

cheers

[quote author="Piker" date="1289024136[/quote]

No one should use that drawing... it's just wrong for thermal storage. That's not even a good way to pipe a large buffer tank.

To be honest, I don't think you really even need circulation through the boiler below 150... water will move throughout the vessel via convection until the vessel hits 150 and the circulator turns on. This is how some of the european gasifiers operate, including the Froling FHG. I would not set up an econoburn like that, however, unless they provided a written addendum to your warranty that approves the design.

According to what the Tech team at Tarm says, the pressure drop across an 1 1/4" termovar mixing valve is negligible, so plumbing an 1 1/4" valve into an 1 1/2" system will be fine. You also have to consider, that your storage will be running a pretty good sized delta T most of the time... you might be sending 165 or 170° water to the top of the tank and returning 110 or 120... with that kind of a delta T, you don't need much flow anyways. Actually, the termovar loading units that we use on even the big solo plus boilers (200,000 Btu) just use a little 15-58 grundfos. You might only get 10 or 12 gpm to a closed loop storage tank... but that's all you need.

cheers[/quote]

Thanks for your response - It makes sense. I am planning on a 15-58 to the thermal storage and I expect that the head loss at 12gpm will be about 5ft. Should be no problem for this pump. Seems that the econoburn should follow the Tarm configuration.

Steve

No one should use that drawing... it's just wrong for thermal storage. That's not even a good way to pipe a large buffer tank.

To be honest, I don't think you really even need circulation through the boiler below 150... water will move throughout the vessel via convection until the vessel hits 150 and the circulator turns on. This is how some of the european gasifiers operate, including the Froling FHG. I would not set up an econoburn like that, however, unless they provided a written addendum to your warranty that approves the design.

According to what the Tech team at Tarm says, the pressure drop across an 1 1/4" termovar mixing valve is negligible, so plumbing an 1 1/4" valve into an 1 1/2" system will be fine. You also have to consider, that your storage will be running a pretty good sized delta T most of the time... you might be sending 165 or 170° water to the top of the tank and returning 110 or 120... with that kind of a delta T, you don't need much flow anyways. Actually, the termovar loading units that we use on even the big solo plus boilers (200,000 Btu) just use a little 15-58 grundfos. You might only get 10 or 12 gpm to a closed loop storage tank... but that's all you need.

cheers[/quote]

Thanks for your response - It makes sense. I am planning on a 15-58 to the thermal storage and I expect that the head loss at 12gpm will be about 5ft. Should be no problem for this pump. Seems that the econoburn should follow the Tarm configuration.

Steve

Jeff S

Feeling the Heat

In Hot Water - Would you mind stating the differential control device you are using for your set up.I am aware of the Tekmar 157 with variable speed there may be others ,but I would like to incorporate something like your design into my own system.

Thanks Jeff

Thanks Jeff

wood thing

Member

The by-pass circ is located per ecconoburn manual. There is no mention of a mixing valve. I don't understand the reason for both. I don't have graphics so will try to explain my set up. The primary circ (a) is used to charge storage when the boiler is over 150 and there is no demand at the house. A third circ (b) is installed for the primary loop controled by a demand relay. I also installed a second relay to disable circ (a) and open a zone valve that ties the boiler supply directly to the primary loop. All return waters go thru the boiler. I have been using a simple timer to shut off the boiler after a complete burn (boiler cold - all heat out of storage). Now that its getting colder and the boiler requires more firing, I'm not sure if i will use the timer. Hope this helps. By the way, I like Dale and all have been fast to reply.

wood thing said:The by-pass circ is located per ecconoburn manual. There is no mention of a mixing valve. I don't understand the reason for both. I don't have graphics so will try to explain my set up. The primary circ (a) is used to charge storage when the boiler is over 150 and there is no demand at the house. A third circ (b) is installed for the primary loop controled by a demand relay. I also installed a second relay to disable circ (a) and open a zone valve that ties the boiler supply directly to the primary loop. All return waters go thru the boiler. I have been using a simple timer to shut off the boiler after a complete burn (boiler cold - all heat out of storage). Now that its getting colder and the boiler requires more firing, I'm not sure if i will use the timer. Hope this helps. By the way, I like Dale and all have been fast to reply.

The manual now states that a mixing valve should be used to prevent thermal shock. My initial plan was to setup somewhat like you have Using a Grudnfos 15-58 for both the byapss (procvided with boiler) and for the primariy ciruclator supplying the thermal storage and in addition use a taco 007 for the zone valves supply the house. The obvious issue without the mixing valve is the potential to get cold slugs of water into the boiler when the primary circulator kicks on - and this will likely happen after long off times. This is the reason Dale recommends a mixing valve and why he uses a caleffi on his home setup. At this point with a mixing valve it is uncessary to have a bypass circulator but it won't hurt. What type and size pipe did you use for your system? I like copper size at 1-1/4" but my wallet doesn't.

wood thing

Member

heat4steve said:wood thing said:The by-pass circ is located per ecconoburn manual. There is no mention of a mixing valve. I don't understand the reason for both. I don't have graphics so will try to explain my set up. The primary circ (a) is used to charge storage when the boiler is over 150 and there is no demand at the house. A third circ (b) is installed for the primary loop controled by a demand relay. I also installed a second relay to disable circ (a) and open a zone valve that ties the boiler supply directly to the primary loop. All return waters go thru the boiler. I have been using a simple timer to shut off the boiler after a complete burn (boiler cold - all heat out of storage). Now that its getting colder and the boiler requires more firing, I'm not sure if i will use the timer. Hope this helps. By the way, I like Dale and all have been fast to reply.

The manual now states that a mixing valve should be used to prevent thermal shock. My initial plan was to setup somewhat like you have Using a Grudnfos 15-58 for both the byapss (procvided with boiler) and for the primariy ciruclator supplying the thermal storage and in addition use a taco 007 for the zone valves supply the house. The obvious issue without the mixing valve is the potential to get cold slugs of water into the boiler when the primary circulator kicks on - and this will likely happen after long off times. This is the reason Dale recommends a mixing valve and why he uses a caleffi on his home setup. At this point with a mixing valve it is uncessary to have a bypass circulator but it won't hurt. What type and size pipe did you use for your system? I like copper size at 1-1/4" but my wallet doesn't.

All my piping is 1 1/4" copper except for 1 1/4" pex to the house.

mpoyneer

New Member

Okay - what is the problem with running your circulator 100% of the time through the storage and boiler and the entire system? I realize that the storage tank will stratify when circ's are off, but not so when the water is constantly circulating through it and the entire system.

Consider your water pressure valve: it's on all the time waiting for the pressure in your indoor (propane, natural gas, etc.) boiler to drop, then dumps cold water directly into your indoor boiler at the return side. I would agree that is not the ideal setup, however most indoor systems are setup that way and have been for years.

I think you would be fine circulating all the time as long as the following conditions are true: 1) fill the added storage slowly the first time with the added water coming through your cold water pressure valve OR 2) let the entire system cool down and fill the storage tank through the entire system at 50 degrees and heat the entire loop slowly with small burns to bring it up to operating temp and keep it there.

Thoughts?

Consider your water pressure valve: it's on all the time waiting for the pressure in your indoor (propane, natural gas, etc.) boiler to drop, then dumps cold water directly into your indoor boiler at the return side. I would agree that is not the ideal setup, however most indoor systems are setup that way and have been for years.

I think you would be fine circulating all the time as long as the following conditions are true: 1) fill the added storage slowly the first time with the added water coming through your cold water pressure valve OR 2) let the entire system cool down and fill the storage tank through the entire system at 50 degrees and heat the entire loop slowly with small burns to bring it up to operating temp and keep it there.

Thoughts?

- Status

- Not open for further replies.

Similar threads

- Replies

- 9

- Views

- 2K

- Replies

- 22

- Views

- 1K

- Replies

- 13

- Views

- 748

- Replies

- 1

- Views

- 400