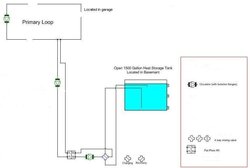

I have a Grundfos 15-58 on the cold side of a flat plate heat exchanger that isn't holding its prime (its pumping air). The diagram attached shows the design I am using. What it doesn't show clearly is that the HX and pump is at ground level in the garage. The tank is in the basement. I have the pump on high speed and the head is within the pump's capacity. Why do you suppose the cold side won't pump?

Unpressurized Storage Pump not Holding its prime

- Thread starter Mushroom Man

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.