I'm enclosing class a chimney that runs through our dining room. I need to keep the 2" minimum to combustibles, which if I use wood studs would enclose a much wanted outlet inside the chase. If I use metal studs turned sideways I can save the outlet. Can my metal studs enter this 2" clearance area? I'm wondering if the heat would conduct through the stud and to the paper on my drywall causing a problem. Thanks for your help.

Metal studs for building a chase through living space

- Thread starter ericj

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

LLigetfa

Minister of Fire

Instead of the traditional 2x4 metal studs, I use 2x2 metal studs so they don't encroach inside the 2" clearance requirement.

Thanks for the heads up about the 2*2 metal studs. What I'd like to do is place those 2*2 metal studs inside the 2" clearance for the chimney so that my drywall begins two inches from the chimney. Possible? (Provided the studs don't actually contact the chimney? Maybe ripping them and keeping a one inch gap.)

Dakotas Dad

Minister of Fire

The way I see it, is 2" to combustibles is, well, just that. If anything closer than 2" is noncombustible, then it's ok.

Since you are doing drywall work anyways, why not just move the outlet? Takes about 20 minutes usually.

Since you are doing drywall work anyways, why not just move the outlet? Takes about 20 minutes usually.

LLigetfa

Minister of Fire

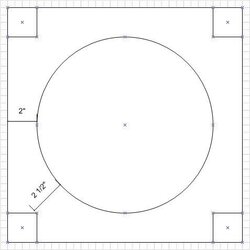

I'm assuming the chimney you speak of is actually round and that the chase will be built square in which case there is room in the corners for the 2x2 studs and still have 2" clearance. I would also go with paperless drywall and I would vent the chase top and bottom.

LLigetfa

Minister of Fire

IMHO it is a 2" clearance requirement, combustible or not. The only exception would be a firestop at the floor and at the ceiling.Dakotas Dad said:The way I see it, is 2" to combustibles is, well, just that. If anything closer than 2" is noncombustible, then it's ok.

Dakotas Dad

Minister of Fire

LLigetfa said:IMHO it is a 2" clearance requirement, combustible or not. The only exception would be a firestop at the floor and at the ceiling.Dakotas Dad said:The way I see it, is 2" to combustibles is, well, just that. If anything closer than 2" is noncombustible, then it's ok.

My chimney instructions said 2" clearance to combustibles, not "to anything". Since the OP gave the same requirement in his question, my guess is his is the same, and I answered accordingly.

Here you go, right from the first page of the instructions: http://www.duravent.com/?page=1b.php seems pretty straight forward to me.

I think I found my answer. The Selkirk Supervent instructions online say:

MAINTAIN A 2" MINIMUM AIR SPACE CLEARANCE BETWEEN INSULATED CHIMNEY SECTIONS AND COMBUSTIBLE MATERIALS.

So the 2" minimum clearance must be "air space." Occupying this space with something, combustible or non-combustible, isn't OK. It's not "airspace" anymore. This is the way I'm understanding it.

So, if I move the outlet I would need to extend the wires from the current outlet box about 1'. Do they make a blank plate with a round knockout that I could screw to the current box? The idea is to run the wire through a wire clamp put in the knock out. (This all has to be up to code. Any other thoughts on how to do this?)

MAINTAIN A 2" MINIMUM AIR SPACE CLEARANCE BETWEEN INSULATED CHIMNEY SECTIONS AND COMBUSTIBLE MATERIALS.

So the 2" minimum clearance must be "air space." Occupying this space with something, combustible or non-combustible, isn't OK. It's not "airspace" anymore. This is the way I'm understanding it.

So, if I move the outlet I would need to extend the wires from the current outlet box about 1'. Do they make a blank plate with a round knockout that I could screw to the current box? The idea is to run the wire through a wire clamp put in the knock out. (This all has to be up to code. Any other thoughts on how to do this?)

Dakotas Dad

Minister of Fire

ericj said:I think I found my answer. The Selkirk Supervent instructions online say:

MAINTAIN A 2" MINIMUM AIR SPACE CLEARANCE BETWEEN INSULATED CHIMNEY SECTIONS AND COMBUSTIBLE MATERIALS.

So the 2" minimum clearance must be "air space." Occupying this space with something, combustible or non-combustible, isn't OK. It's not "airspace" anymore. This is the way I'm understanding it.

So, if I move the outlet I would need to extend the wires from the current outlet box about 1'. Do they make a blank plate with a round knockout that I could screw to the current box? The idea is to run the wire through a wire clamp put in the knock out. (This all has to be up to code. Any other thoughts on how to do this?)

You can't hurt anything by keeping a 2" clearance to "anything", but as I said, I see/read it as clearance to combustibles, which steel studs aren't.

on the electrical box.. shut off electricity, remove cover, remove outlet from wires, run "extension from new "old work" box, and into existing box, through the knock outs. Use wire nuts to attach "extension" to existing wire, push wires back into box, put on plain/blank cover, wire outlet in new box just like it was in the old box. It is almost exactly the same as the wiring going from one outlet/box to the next.

LLigetfa

Minister of Fire

I don't want to beat this 2" to combustibles to death, but I also read that nothing is supposed to be put in that 2" space, combustible or not. They make radiation shields that are 4" (2" each side) bigger than the chimney and the radiation shield is made of metal which is surely non-combustible.

As for the electrical outlet, why can the box not be detached from the stud and moved over without having to extend the wires? By code, the box should have been wired with some slack in it.

As for the electrical outlet, why can the box not be detached from the stud and moved over without having to extend the wires? By code, the box should have been wired with some slack in it.

The electrical box is enclosed behind drywall. I can't access the knockouts on the back of the box, or see the mounting brackets on the side. I think it would be hard to pry or cut loose from the stud. My plan is to turn this outlet box into a junction box and extend wire out the front to run to a new outlet box. I just didn't want to run wire out the wide open front of the box. So I'm looking for a cover plate that will accept a wire clamp/connector.

LLigetfa

Minister of Fire

Why can you not cut away the drywall around the box to move it? Since you will be doing drywall work anyway with the new chase, what's another bit to mud and tape? It is against code to have a hidden junction, so you cannot keep the existing box in place and then cover over it. Mind you, you cound install a vent in the chase near the existing outlet box and call it an access panel so that technically, it isn't an inaccessible hidden junction. I installed vents in my chase top and bottom to cool the chase and reclaim some of the heat that otherwise would go up the chimney.

Dakotas Dad

Minister of Fire

No such critter exists that I know of, and I have spent a bit of time in the home wiring world..

You are not wanting to put the new box in the same wall as the current box, but into the new wall of the chase? If so a person could buy a blank plate and drill a hole in it to insert the clamp into. If this is fairly modern construction, you *probably* have a plastic box which doesn't use seperate clamps, they are push through anchor/traps in the box itself.

LLigetfa: By code, no extra slack is required, but by code the wires must be secured to the stud within 8" of the box. That little tidbit notwithstanding, modern boxes are secured to the stud in such a way that removing them will wreck them, and in my experience, if someone wants to move an outlet, it always works out to be on the wrong side of the stud anyways.

You are not wanting to put the new box in the same wall as the current box, but into the new wall of the chase? If so a person could buy a blank plate and drill a hole in it to insert the clamp into. If this is fairly modern construction, you *probably* have a plastic box which doesn't use seperate clamps, they are push through anchor/traps in the box itself.

LLigetfa: By code, no extra slack is required, but by code the wires must be secured to the stud within 8" of the box. That little tidbit notwithstanding, modern boxes are secured to the stud in such a way that removing them will wreck them, and in my experience, if someone wants to move an outlet, it always works out to be on the wrong side of the stud anyways.

LLigetfa

Minister of Fire

Code or not code... slack or no slack... I'm not here to argue... maybe they do things different in KY. Ever watch Holmes on Homes? Around here we have a loop of slack at the box and my inspector demanded it. If for some reason the wire breaks or comes up short, it can be pulled out a bit.

This is all conjecture anyway. The OP could have conduit or knob and tube, etc. The box could be on the wrong side of the stud. Even if it were, he may be able to drill a hole through the stud and move it to the other side. There is one way to be sure, remove some drywall and have a look. I mean, most of it will be hidden by the chase anyway so what's the big deal?

This is all conjecture anyway. The OP could have conduit or knob and tube, etc. The box could be on the wrong side of the stud. Even if it were, he may be able to drill a hole through the stud and move it to the other side. There is one way to be sure, remove some drywall and have a look. I mean, most of it will be hidden by the chase anyway so what's the big deal?

I don't really understand what a, "chase" is, even though I hear/read the terminology frequently. I understand what a masonry chimney is, but I don't fully understand the different parts that comprise the "chimney" in total. Would someone explain it to me quickly or direct me to something that spells it out in "in plain english"?

LLigetfa

Minister of Fire

A chase is a wall around the chimey to protect inhabitants from touching the hot chimney and for cosmetics.

So, the rough, cinderblock "face" of the "masonry chimney" in my workroom that I faced with multiple surface "skim coats" to smooth out the cinderblock surface is the "chase", right? The "chase" is the part of the chimney that I see from inside the room? Our chimneys are inside our home and inside the baHn, so we see the chimney from inside our living/working spaces. Thanks! I think I "get it" now.

LLigetfa

Minister of Fire

I would not consider a skim coat of plaster over a masonry chimney as a "chase". In many jurisdictions, even a masonry chimney may need to have clearance to combustibles and as such there is often an air space between it and a chase. In the case of ericj, he is chasing in a class A metal chimney which in most jurisdictions is required to keep the occupants from touching the hot steel.

Thank your for your reply. I now at least understand the basics of a "chase" and I also understand that the finishing details of a "chase" may vary greatly depending on local code. And the recommended clearances dictated by the stove/insert manufacturer. Thanks!

santacruzbluz

New Member

A "chase" can be any enclosed space that piping, ducting, or even electrical wires run through, built to protect them or hide them.

As for the 2" space question, I don't see how some metal studs coming up through that space would compromise the "air space" requirement. I think the air space will still perform its job with the studs there, and would use them.

As for the 2" space question, I don't see how some metal studs coming up through that space would compromise the "air space" requirement. I think the air space will still perform its job with the studs there, and would use them.

LLigetfa

Minister of Fire

C'mon, quit bein' a dink.

Some of us ask questions that may seem really stupid to you, but are honestly posed.

I may be a complete fool to you but the questions I pose may be uimportant to someone who's just stumbled onto this website. If you don't wish to participate DON'T!

But spare us your "thinly disguised contempt".

Some of us ask questions that may seem really stupid to you, but are honestly posed.

I may be a complete fool to you but the questions I pose may be uimportant to someone who's just stumbled onto this website. If you don't wish to participate DON'T!

But spare us your "thinly disguised contempt".

Renovation

New Member

LLigetfa said:I don't want to beat this 2" to combustibles to death, but I also read that nothing is supposed to be put in that 2" space, combustible or not. They make radiation shields that are 4" (2" each side) bigger than the chimney and the radiation shield is made of metal which is surely non-combustible.

To continue the beating and hair splitting, one function of the attic shield is to hold combustibles (insulation, that 2x4 someone leaned against it--a very nasty story) at least 2" away from the chimney, which means the shield has to be at least 2" away from the chimney.

FWIW, my experienced HVAC/Furnace/fireplace installer said there is no combustion danger from having metal, like studs/ducts within 2", or even touching the chimney.

LLigetfa

Minister of Fire

I don't understand why you want to hang on the literal wording "CTC". Fill the 2" void with concrete and see if it will pass inspection. The purpose of 2" of air is insulation. A thermally conductive metal or concrete put in the space (both non-combustible), would not provide the required insulation.RenovationGeorge said:To continue the beating and hair splitting...

If you put shorter legs on a stove, you would have to make up the lost R-value from less air space by having more R-value in masonry. The length of the legs insure the distance is maintained.

Anyway, as per the pic I drew, I would still like to hear from ericj, how there can not be enough clearance for 2" metal studs in the corners.

LLigetfa said:I don't understand why you want to hang on the literal wording "CTC". Fill the 2" void with concrete and see if it will pass inspection. The purpose of 2" of air is insulation. A thermally conductive metal or concrete put in the space (both non-combustible), would not provide the required insulation.RenovationGeorge said:To continue the beating and hair splitting...

If you put shorter legs on a stove, you would have to make up the lost R-value from less air space by having more R-value in masonry. The length of the legs insure the distance is maintained.

Anyway, as per the pic I drew, I would still like to hear from ericj, how there can not be enough clearance for 2" metal studs in the corners.

Thanks for your reply. I have plenty of room for studs in the corner. The issue would be the bottom and top plate - that anchor to the floor and ceiling - that run along one side of the chase. These top and bottoms plates would fall within the clearance zone because I need the drywall to begin right at two inches (to save the outlet). I could float the drywall, that is, not anchor it to anything at the top and bottom, just to the vertical studs. Would this pass muster for code? It would only be about 1' at the top and bottom of the chase between two studs where the drywall isn't anchored.

- Status

- Not open for further replies.

Similar threads

- Replies

- 21

- Views

- 1K

- Replies

- 1

- Views

- 814

- Replies

- 1

- Views

- 4K

- Replies

- 9

- Views

- 365