Gday all, now the weather is warm here in Aus I want to try and get some more go out of my new wood stove. Brought it just before winter this year and was very disappointed.

I got this type because it had the secondary burn (didn’t know what that was till I started looking around then come on here) and a nice size fire box but it does not work at all. The secondary burn is a square tube (you cab see the square hole in my drawing) that runs from one side to the other just in front of the baffle with about 20 holes in it. Even when I got this thing really hot after leaving both air controls open then shutting them closed all I could see was little pockets of air blowing into the flames coming around the baffles, then as it died down and started to smoke ...nothing.

I can also only get 7 hours burn time with dry hard wood. I have modded the air controls so I can shut it down more than factory, still no good

After doing a fair bit of searching and reading I have come up with this.

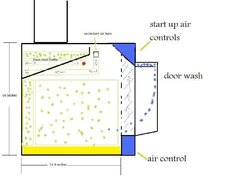

The stuff in green is what I want to add.

It has 7 and a half 4.5" x 9" x 1" fire bricks in the bottom. I want to add another 15 bricks in there, along the back and around both sides also remove the steel baffle and but the rest of the bricks up there, to add some mass and hopefully reflect some of the heat back into the fire.

With the secondary burn I want to use the existing holes and run the preheat pipe along the side, half way along the back, do a "U" turn head back folowing the same path then come out to the middle of the fire box just below the new brick baffle. The other side will be a mirror image.

Question are should I just mount the new fire brick baffle on the same angle as the steel one was (the easy way) or weld on a new frame to make it level like in my drawing? also should I make the new baffle longer (extending towards the front more) so the smoke have a longer parth to travel?

and finally do u think the tubes will be long enough to work? each side will be about 52" long and all of it will be right up the top where all the heat should be.

Any comments would be greatly appreciated

Thanks Shane

I got this type because it had the secondary burn (didn’t know what that was till I started looking around then come on here) and a nice size fire box but it does not work at all. The secondary burn is a square tube (you cab see the square hole in my drawing) that runs from one side to the other just in front of the baffle with about 20 holes in it. Even when I got this thing really hot after leaving both air controls open then shutting them closed all I could see was little pockets of air blowing into the flames coming around the baffles, then as it died down and started to smoke ...nothing.

I can also only get 7 hours burn time with dry hard wood. I have modded the air controls so I can shut it down more than factory, still no good

After doing a fair bit of searching and reading I have come up with this.

The stuff in green is what I want to add.

It has 7 and a half 4.5" x 9" x 1" fire bricks in the bottom. I want to add another 15 bricks in there, along the back and around both sides also remove the steel baffle and but the rest of the bricks up there, to add some mass and hopefully reflect some of the heat back into the fire.

With the secondary burn I want to use the existing holes and run the preheat pipe along the side, half way along the back, do a "U" turn head back folowing the same path then come out to the middle of the fire box just below the new brick baffle. The other side will be a mirror image.

Question are should I just mount the new fire brick baffle on the same angle as the steel one was (the easy way) or weld on a new frame to make it level like in my drawing? also should I make the new baffle longer (extending towards the front more) so the smoke have a longer parth to travel?

and finally do u think the tubes will be long enough to work? each side will be about 52" long and all of it will be right up the top where all the heat should be.

Any comments would be greatly appreciated

Thanks Shane