I've presently got a shop, 28*48, with 4 loops of 1/2 pex feeding the floor. It is currently running off of a baxi. There is a "header" loop of 1" copper and the floor feeds off of close spaced tees. Floor pump is currently wired to run continually. I plan on hooking a plate style exchanger fed by a boiler and run the floor pump off of a line voltage thermostat and shut off the baxi.

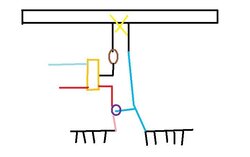

I wanted to run from the pump to the HX to the floor. Can I use one of the three way mixing valves like this;

https://www.hearth.com/econtent/index.php/forums/viewthread/65991/P15/

look at post # 20

Can I run my pump into the top with my return from the slab into the right? Keep in mind there are close spaced tees just above this.

I would rather not temper the water coming from the boiler just in case I, in the future, want to put in a forced air liquid to air exchanger for those "need heat right now" situations, as I usually keep the shop in the low to mid 50's.

I have thought about a valve trio but I would rather have something I could "set and forget".

I wanted to run from the pump to the HX to the floor. Can I use one of the three way mixing valves like this;

https://www.hearth.com/econtent/index.php/forums/viewthread/65991/P15/

look at post # 20

Can I run my pump into the top with my return from the slab into the right? Keep in mind there are close spaced tees just above this.

I would rather not temper the water coming from the boiler just in case I, in the future, want to put in a forced air liquid to air exchanger for those "need heat right now" situations, as I usually keep the shop in the low to mid 50's.

I have thought about a valve trio but I would rather have something I could "set and forget".