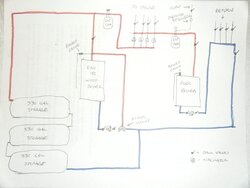

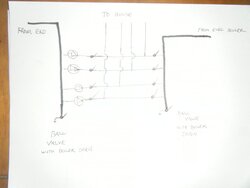

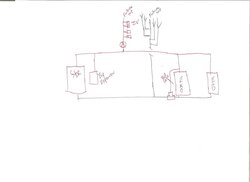

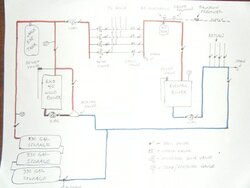

Here I am again still looking for some additional help on Installing my EKO 40. I am still not sure where I need to install Check Valves, Backflow Preventers, Pressure Guages, Temperature Gauges and such.

I have revised my drawing since my last post so my mixing valve isn’t before the storage, and after re-reading replies from my november posts, I think I need to connect my 1-1/4†supply from the wood boiler to the electric boiler so when the house isn’t demanding heat, the wood boiler can push the heated water thru the electric boiler into the storage. Hopefully,someone can confirm or deny this.

I am actually hoping that someone will actually print out my drawing and pencil in exactly where I need to put my pumps, check valves, backflow preventers, aquastats etc, and then repost or email me directly. I am not afraid to do the work, I just lack the confidence to make the decisions.

I have reviewed nofossil’s “Simplified Plumbing with Storage†and have found it very helpful, but lacks detailed info as to where to put these items, or even if they are needed. Also, the location of my storage relative to my boilers is not the same as in the sketches in this chat room.

I also have a qestion on the Taco pump that was provided with my install kit. I noticed that the flange kit is 1-1/4†which is what most of my system is, however, it appears that the opening on the pump is about 3/4†to 1†diameter. Is this supposed to be this way?

If I choose to use 4 circ pumps instead of zone valves, can I eliminate the other pumps? Which is better?

Looking forward to anyone’s input.

I have revised my drawing since my last post so my mixing valve isn’t before the storage, and after re-reading replies from my november posts, I think I need to connect my 1-1/4†supply from the wood boiler to the electric boiler so when the house isn’t demanding heat, the wood boiler can push the heated water thru the electric boiler into the storage. Hopefully,someone can confirm or deny this.

I am actually hoping that someone will actually print out my drawing and pencil in exactly where I need to put my pumps, check valves, backflow preventers, aquastats etc, and then repost or email me directly. I am not afraid to do the work, I just lack the confidence to make the decisions.

I have reviewed nofossil’s “Simplified Plumbing with Storage†and have found it very helpful, but lacks detailed info as to where to put these items, or even if they are needed. Also, the location of my storage relative to my boilers is not the same as in the sketches in this chat room.

I also have a qestion on the Taco pump that was provided with my install kit. I noticed that the flange kit is 1-1/4†which is what most of my system is, however, it appears that the opening on the pump is about 3/4†to 1†diameter. Is this supposed to be this way?

If I choose to use 4 circ pumps instead of zone valves, can I eliminate the other pumps? Which is better?

Looking forward to anyone’s input.