Definition of secondary burn?

- Thread starter mywaynow

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

LLigetfa

Minister of Fire

Secondary burn is where superheated air is introduced to the flame path away from the fuel source to extend the flame.

Backwoods Savage

Minister of Fire

In other words, it is the smoke and gasses being burned further before exiting the stove. This is extra heat you would not have gotten plus you aren't pouring bad things into the outdoor air.

As LL and Backwoods said. However, a picture is worth 1000 words.

(turn your sound down now, I'm no movie maker)

This, and more information that you may find useful was pulled from this thread https://www.hearth.com/econtent/index.php/forums/viewthread/65174/

Good luck,

pen

(turn your sound down now, I'm no movie maker)

This, and more information that you may find useful was pulled from this thread https://www.hearth.com/econtent/index.php/forums/viewthread/65174/

Good luck,

pen

Backwoods Savage

Minister of Fire

Backwoods Savage said:Nice show Pen.

I can't believe I was missing with the old stove.

pen

Backwoods Savage

Minister of Fire

Renovation

New Member

mywaynow said:Is my older VC Defiant able to do this? Or, is it only newer catalytic stoves?

Newer, EPA type stoves do it.

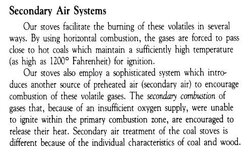

There are two kinds. The first is a thermal, non-catalytic method, that injects superheated air, usually at the top of the firebox, to burn the smoke coming off the fire at about 1200. They produce a lovely floating/rolling flame at the top of the firebox, like the non-cat does in the video above.

The second type is catalytic, which has the exiting smoke pass through a honeycomb covered in a catalyst, which allows the smoke to ignite at only 600 degrees. Catalysts are usually pretty hidden from sight, and glow rather than flame. Often the view is more smoky, and not the spectacular flame presentation of a non-cat. The upside is more efficiency, and having the option to burn slower and cooler.

So the short answer is no, older stoves generally can't do it. But the good news is the stove in the video is relatively affordable and, if you give it the right chimney and wood that's seasoned at least a year, can burn about half as much wood. How's that for a win-win?

Caveat--I'm a newbie and might be wrong.

HTH

So the exhuast redirect baffle in the VC I have does not accomplish any reburn? It is just a means of holding the hot air within the stove longer, as opposed to the top exhaust? Just for clarification, the exhaust on the VC Defiant can be routed to the bottom of the stove, opposite the air inlet.

Renovation

New Member

mywaynow said:So the exhuast redirect baffle in the VC I have does not accomplish any reburn? It is just a means of holding the hot air within the stove longer, as opposed to the top exhaust? Just for clarification, the exhaust on the VC Defiant can be routed to the bottom of the stove, opposite the air inlet.

Oops, my mistake--told you I'm a newbie!

I believe your stove has a variation of the air-injection technique called downdraft of everburn, that burns the smoke in a chamber towards the rear of the stove. If I'm correct, it does the same thing as the stove in the video, only more out of sight, and it's sometimes harder to get that secondary burn going.

If you search on the threads you'll find a lot of discussion on that. The VCs and the lopi leyden both use variations of that technique I believe.

So you have the same challenge of getting the secondaries going, which provides the most efficient burn--you'll know you're doing it when little or no smoke comes out your chimney, and I think with everburn there's a rumble. I hope experienced folks (there are many of them here) will chime in, and you can search for it too.

HTH!

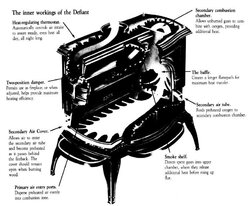

The Defiant had one of the early secondary combustion systems. It is a pretty sophisticated stove. The little port on the left side is the secondary air intake. It should be left open for secondary combustion.

Attachments

Thanks for the info. I believe I am getting a secondary burn once the temps rise and the wood has "settled" into a consistent burn. Most of the time the exhuast is very light to no smoke, after the original load come to a nice burn. I do hear a rumble when I am initiating a new load. Typically, I am loading on top of coals only. I use a method I read about on the forum called "zipper" method. Lining the coals up lengthwise from the side door towards the lower exhaust. Two split logs either side of the coals, and then a "lid" log, flat on the side facing down that creates a tunnel over the coals. I never need to add kindling doing this. It may take a couple minutes, but eventually the ignition starts, and within a minute you hear what sounds like your oil burner. The air is being sucked down that tunnel creating some serious heat. I let this go for a couple minutes, and then change the exhuast to straight out the top. This allows the flames to spread a bit more. Then it's back to the lower exhaust, load a couple more logs and shut the door. I am good for 3-4 hours at 50-60% of the box loaded. If I load it full and slow the air I can get 6-7 and still have a coal bed. The Cape is over 70 degrees with the outside temps in the 20s, no oil burning. I am content with that.

Renovation

New Member

Yay! I told you someone knowledgeable would be along.

My description was in the general neighborhood, but not quite right.

I think I've heard secondary burning on those stoves with the horizontal path engaged called "burning horizontal". Yes, there it is in the manual.

Wow, it even has a thermostat! Sophisticated indeed! So there's an early non-cat with a thermostat. I didn't know that.

Do you have the manual for your stove, MyWayNow?

My description was in the general neighborhood, but not quite right.

I think I've heard secondary burning on those stoves with the horizontal path engaged called "burning horizontal". Yes, there it is in the manual.

Wow, it even has a thermostat! Sophisticated indeed! So there's an early non-cat with a thermostat. I didn't know that.

Do you have the manual for your stove, MyWayNow?

Renovation

New Member

mywaynow said:Thanks for the info. I believe I am getting a secondary burn once the temps rise and the wood has "settled" into a consistent burn. Most of the time the exhuast is very light to no smoke, after the original load come to a nice burn. I do hear a rumble when I am initiating a new load. Typically, I am loading on top of coals only. I use a method I read about on the forum called "zipper" method. Lining the coals up lengthwise from the side door towards the lower exhaust. Two split logs either side of the coals, and then a "lid" log, flat on the side facing down that creates a tunnel over the coals. I never need to add kindling doing this. It may take a couple minutes, but eventually the ignition starts, and within a minute you hear what sounds like your oil burner. The air is being sucked down that tunnel creating some serious heat. I let this go for a couple minutes, and then change the exhuast to straight out the top. This allows the flames to spread a bit more. Then it's back to the lower exhaust, load a couple more logs and shut the door. I am good for 3-4 hours at 50-60% of the box loaded. If I load it full and slow the air I can get 6-7 and still have a coal bed. The Cape is over 70 degrees with the outside temps in the 20s, no oil burning. I am content with that.

Okay, sweet. So you are on top of things and a secondary-burner indeed. It looks like you've learned your setup's personality.

BeGreen uses a similar log arrangement, NS, minus the lid log, to start fires. He calls it most unprovocatively the Tunnel of Love. :lol:

No manual. Begreen, you have confirmed yet again the talent and high participation level that amazes me on this site. I posted a question a few weeks ago about the thermostat on this stove. Within 15 minutes, someone posted a diagram of the thermostat. This forum is so informative. And this is happening at 4 am too.

That thermostat is working fantastic now that it is correctly installed. When I installed this stove, which I received gratus from a customer of mine, the problem I was having was that the stove would get so hot, and progessively. It turned out the thermostat was backwards; opening the air inlet more as heat increased. Obviously that is not the designer's intention. Now that t is properly operating, the stove burns quite consistently.

That thermostat is working fantastic now that it is correctly installed. When I installed this stove, which I received gratus from a customer of mine, the problem I was having was that the stove would get so hot, and progessively. It turned out the thermostat was backwards; opening the air inlet more as heat increased. Obviously that is not the designer's intention. Now that t is properly operating, the stove burns quite consistently.

mywaynow said:Is my older VC Defiant able to do this? Or, is it only newer catalytic stoves?

More than a few pre-EPA-compliant stoves had provision for secondary burning, without any pricy goodies like cats.

Even the very inexpensive mid-80s-vintage Supra I ran for years had a moderately effective secondary air preheater, and discharged

that air near the top of the firebox.

VC, IIRC had a means of preheating secondary in a cast-in channel in the firebox and discharging that air into the exhaust from the

firebox so the next chamber of the stove was for secondary burning. IIRC the Defiant & Vigilant had such.

The problem is to get a sufficiently pre-heated flow of adequate amount, without destroying efficiency. Took people a while.

The rubber hit the road, so to speak, when the exhaust particulates had to be measured and not exceed the limit.

LLigetfa

Minister of Fire

Over 30 years ago, I heated with a top loading round vertical wood burner that employed two hollow channels in the firebrick as downdraft reburners. It even had a bi-metal thermostat. Unlike the modern EPA stoves, that one didn't need the wood to be seasoned for years in advance. I wish I could remember the brand. It was made in Quebec. It was already an old stove back then, and the sheet metal "cylinder" portion was all rusted away. A friend made a new one out of much heavier sheet metal.CTYank said:More than a few pre-EPA-compliant stoves had provision for secondary burning, without any pricy goodies like cats...

branchburner

Minister of Fire

The old Defiant is a great stove. I think it was ahead of its time, in that people generally didn't understand secondary combustion and the need for dry wood and the correct balance of air. Like many people, we burned ours like it was a plain, big old metal box, simply shutting the air supply off when it got too hot. As a result, it smoldered and produced creosote and did not live up to its potential efficiency. Only 30 years later, after buying an EPA stove, do I realize I grew up with a truly sophisticated stove.

woodchip

Minister of Fire

My little regal has a secondary burn, the primary in the wood comes from the air from the door inlets, keeping the glass clean (usually called airwash), and the secondary burn comes from the soot and other bits of carbon in the exhaust gases being burnt by the warm air inlet just below the baffle plate. In modern woodburners (and it is noticeable in mine), the baffle plate is carefully shaped, and extended almost to the front of the burner just above the door, with the hot gases being circulated in the woodburner for as long as possible. This means the efficiency of the secondary burn is at it's maximum, keeping the stove hottest where you want the most heat, at the front, and helping ensure that the combustable materials have been fully burned before exiting up the flue.

And the most important bit about secondary burns is that you must use well seasoned wood, otherwise the mix of steam from wet wood mixed with the exhaust gases will slow or stop the secondary burn taking place, which effectively cuts the woodburners efficiency by as much as 50%, even more on the most efficient ones.

I love my secondary burn, all that extra free heat from my wood

And the most important bit about secondary burns is that you must use well seasoned wood, otherwise the mix of steam from wet wood mixed with the exhaust gases will slow or stop the secondary burn taking place, which effectively cuts the woodburners efficiency by as much as 50%, even more on the most efficient ones.

I love my secondary burn, all that extra free heat from my wood

Battenkiller

Minister of Fire

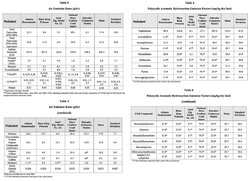

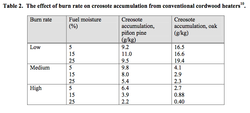

A while back, Environment Canada did an emissions study of five conventional stoves and came up with some interesting data. All of the stoves were well-used, donated for the test by folks around the country. They were chosen to represent examples of what a typical homeowner might be using at the time of the study. The testing was done by developing a protocol that would best represent a real-world "medium" burn rate of about 6 hours of usable heat using conventional cordwood as fuel. So, no, they weren't opened to the max or anything. They were trying to burn these stoves like an ordinary homeowner might use one as a space heater in his or her home. The completion of the combustion was defined when the flue gas temperature cooled to 200ºF as measured at the center of the chimney at 12" above the heater. At 200º the combustion process was considered essentially complete and the heater would no longer be considered as producing useful heat.

Two of the stoves (a Jotul 121 and a Schrader) tested under the EPA allowable maximum for particulate emissions (7.5 g/hr), and the old BK Princess (non-cat version) came real close at 8.6 g/hr. Most notably, the Jotul 121 "Elg" (a box stove built like the 118 only larger) not only achieved a breathtakingly low 3.1 g/hr total particulate emissions, it also had astoundingly lower emissions for the real nasty stuff, like benzene, benzo(a)pyrene, formaldehyde, phenols, etc. - from 10-40 times lower than the others. This says something about what can be done inside a well designed stove without the aid of any secondary combustion. In addition, both the Atlanta Homesteader and the BK Princess were able to achieve a measured 63% real-world total efficiency. This is using the actual low-heat value of the fuel, not the bogus high-heat value that creates a false number of 75% efficiency that can never really be achieved without condensing all the water of combustion inside the home. These tests were done using real cordwood rather than the EPA test charge. Specifically, they used naturally-seasoned, locally available white oak that was in the 15-25% MC range.

BTW a similar study in New Zealand during the same time period examined 12 stoves (don't know which ones) with very similar findings (about 10.0 g/hr on the average) across the board. Only a couple grams less particulates per hour and they would have passed the EPA test with flying colors.

And, yes, the early VC stoves were way ahead of their time. I am glad I finally have one. It is a rugged heat-meister, and a joy to own and operate... especially now that I actually have it together correctly. And if it ain't cleaner and more efficient than some old box stove, I'll eat the damn thing in front of a live Hearth.com audience.

EDIT: I forgot to attach the test data. :roll:

Two of the stoves (a Jotul 121 and a Schrader) tested under the EPA allowable maximum for particulate emissions (7.5 g/hr), and the old BK Princess (non-cat version) came real close at 8.6 g/hr. Most notably, the Jotul 121 "Elg" (a box stove built like the 118 only larger) not only achieved a breathtakingly low 3.1 g/hr total particulate emissions, it also had astoundingly lower emissions for the real nasty stuff, like benzene, benzo(a)pyrene, formaldehyde, phenols, etc. - from 10-40 times lower than the others. This says something about what can be done inside a well designed stove without the aid of any secondary combustion. In addition, both the Atlanta Homesteader and the BK Princess were able to achieve a measured 63% real-world total efficiency. This is using the actual low-heat value of the fuel, not the bogus high-heat value that creates a false number of 75% efficiency that can never really be achieved without condensing all the water of combustion inside the home. These tests were done using real cordwood rather than the EPA test charge. Specifically, they used naturally-seasoned, locally available white oak that was in the 15-25% MC range.

BTW a similar study in New Zealand during the same time period examined 12 stoves (don't know which ones) with very similar findings (about 10.0 g/hr on the average) across the board. Only a couple grams less particulates per hour and they would have passed the EPA test with flying colors.

And, yes, the early VC stoves were way ahead of their time. I am glad I finally have one. It is a rugged heat-meister, and a joy to own and operate... especially now that I actually have it together correctly. And if it ain't cleaner and more efficient than some old box stove, I'll eat the damn thing in front of a live Hearth.com audience.

EDIT: I forgot to attach the test data. :roll:

Attachments

Renovation

New Member

The manual for this stove covers all of the early VC stoves. It is posted in 2 parts here:

https://www.hearth.com/econtent/index.php/wiki/Vermont_Castings_Older_Stove_Models/

https://www.hearth.com/econtent/index.php/wiki/Vermont_Castings_Older_Stove_Models/

Battenkiller

Minister of Fire

RenovationGeorge said:Thanks Battenkiller, for a great read. Very cool.

Yeah, I could get lost in all the good data I find on the Internet. A lot of the government stuff is hard to pass along on a board such as this because the clickable links all lead to direct downloads of PDFs. I have hundreds of similar documents stored on my computer from over 10 years of online research, but they are all in PDF format. Same in this case. I can't get a direct link to that PDF, but if you follow the link below, you can get the document by clicking the link at the top of the list:

EPA Emissions PDFs

The article listed right below that one is even more fascinating. It compares emissions as a function of burn rate, showing that low burn rates are dirtier than high burn rates by a factor of 48 in hardwood like oak. The implication is that occasional burners and other folks who are burning at very low rates "just to take the chill out" are the worst offenders, pollution wise.

There is a huge sacred cow getting toppled in that study as well. You can see by the table below that at low burn rates, wood at 25% MC makes a bit more creosote than wood at 15% MC, but that trend reverses itself at higher burn rates. In fact, oak at 5% MC forms almost 7 times as much creosote at high burn rates as wood at 25% MC. It appears that kiln-dried hardwood is a very dirty burn indeed. Also, dense hardwoods at 25% MC produces only half the creosote that is formed by burning wood at 15% MC. Of course, I expect to here a chorus of BS being called on this info. After all, it's only scientific data, not hardcore anecdotal evidence. %-P Would it help to add that this data was gathered during in-home testing?

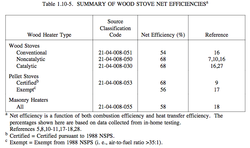

Further down there is an article about net efficiencies. Right from the EPA's mouth, the older stoves average 54% net efficiency, whereas both cat and non-cat stoves average only 14% higher in net efficiency at 68%. As the footnote states, net efficiency is a function of both combustion efficiency and heat transfer efficiency. It is the heat you actually get released into your home. 54% ain't so bad when folks are constantly claiming the old stoves are more like 30% efficient, and that you'll half your wood usage with the same amount of heat just by switching to an EPA stove. Well, I've been calling BS on that notion for years now. Maybe I can get a job with the EPA. ;-)

Attachments

graycatman

Member

Re BK's table on creosote formation: how interesting...and timely! Just burned the driest split in my stack-piece I bought last year as kiln dried at the grocery (my first year of burning). Put it on some hot coals with another split, and got strong secondaries immediately. I did cut the air back pretty quickly, but in stages. The dry split was off to one side of my firebox, and the glass on that side collected a coating of light black (although you can see through it). This has never happened to me before-usually a little bit in the lower corners after a few fires. I had cleaned the glass this morning. Burn rate was at least medium, maybe even high, since the thing took off. I was wondering why such a dry piece of wood with strong secondaries would dirty my glass-!

- Status

- Not open for further replies.

Similar threads

- Replies

- 6

- Views

- 455

- Replies

- 11

- Views

- 1K

- Replies

- 8

- Views

- 2K

- Replies

- 12

- Views

- 1K