1. I am getting a lot of creosote build up that I can not open the damper or the door without using a hammer. The wood is very dry cut 2 years ago. I have about 3 feet of single wall black pipe and the rest is triple wall pipe. I was told to insulate the single wall pipe but have not found the insulation to do it yet.

2. When I load it at night I wake up the next morning with the thing almost still full of wood with fuel indicator on.

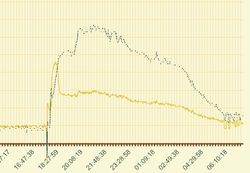

3. I have 1000 gallon storage t that seems to be taking for ever to heat up. the boiler gets to about 150f and then it drops down to 130. This happens over and over. I have not seen it get up over 160 yet. I think because the water coming back into the boiler just is not hot enough yet and keeps cooling the boiler down. I do have a 3 way mixing valve.

4. I still have to set all the air intake settings. I have been messing with the fan air intake and that is all. I have that open all the way.

thanks for the help

2. When I load it at night I wake up the next morning with the thing almost still full of wood with fuel indicator on.

3. I have 1000 gallon storage t that seems to be taking for ever to heat up. the boiler gets to about 150f and then it drops down to 130. This happens over and over. I have not seen it get up over 160 yet. I think because the water coming back into the boiler just is not hot enough yet and keeps cooling the boiler down. I do have a 3 way mixing valve.

4. I still have to set all the air intake settings. I have been messing with the fan air intake and that is all. I have that open all the way.

thanks for the help