When venting through a 100% brick wall (no drywall, no plaster, no lath, no studs, etc etc just brick and mortar) what is the diameter of the smallest circular hole that can be used for a stove that has a 6" vent, given code restrictions and available venting components? I asked at one company and was told the circle would have to be 14.5" diameter. Although I am completely inexperienced at this, having never had a wood stove, 14.5" seems like an awfully big hole to me for a 6" stove-vent. Is the O.D. of double-walled 6" I.D. chimney pipe 14.5" ? Are smaller-diameter thimbles available for non-combustible walls that would still meet code?

venting through 100% brick and mortar: smallest circular hole allowed / possible for a stove with 6"

- Thread starter tr123

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

If the wall is 100% non-combustible, then you need a hole just big enough to put in a thimble, typically clay. The people that you talked to are talking about a super thimble, or some such thing, designed to pass through a combustible wall in order to access a masonry chimney. Is there a masonry chimney in place? Masonry chimneys typically have a clay thimble. If you are adding a thimble, you need to make sure there are no other open thimbles or appliances using this chimney.

summit

Minister of Fire

as long as there is 12" of solid masonry around the thimble to combustible surfaces then all you need is a hole big enough to pass the pipe thru into your chimney. I would reccommend using a stainless sleeve instead of clay or a galvinized thimble to make the connection, as the stainless will not rot out.

Thanks for the replies. No existing chimney is involved: daylight on the outside of the wall, and it's solid masonry a minimum of 3 feet from the hole in all directions. On an online vendor's website I found something called a Double-Wall 6-Inch Black Stovepipe to Masonry Chimney Adaptor - For Solid-Fuel Stoves. It has a stainless pipe inside a black collar and the stainless pipe is 12" in length. Would that be suitable for passing through a wall to daylight where it would meet a Class A stainless chimney pipe?

Does the black stove pipe coming from the stove fit *over* the black adapter pipe, or into it? How is the stove pipe attached/secured to the adapter? Is there a gasket? Or do the pipe and the adapter get cemented, or sealed with high-temp silicone?

Does the black stove pipe coming from the stove fit *over* the black adapter pipe, or into it? How is the stove pipe attached/secured to the adapter? Is there a gasket? Or do the pipe and the adapter get cemented, or sealed with high-temp silicone?

are we talking solid concrete or concrete block? If it's concrete block and you cut your hole, I'd stuff the hole in the cores of the blocks above your pass through full of insulation.

It appears that the black pipe just slides into the end of that pipe you've shown.

pen

It appears that the black pipe just slides into the end of that pipe you've shown.

pen

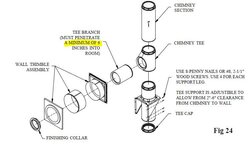

It sounds like you would be best with a Class A tee system, install it like you are passing through any other wall, you just won't have to worry about making such a huge hole. By doing this you won't have to worry about adapring over to class A.

@Webby: do you mean this?

outside the wall, with a piece of stainless chimney pipe that connects to the horizontal opening passing through the wall? Does the indoor double-walled black stove pipe simply screw into the stainless chimney segment that passes through the wall?

outside the wall, with a piece of stainless chimney pipe that connects to the horizontal opening passing through the wall? Does the indoor double-walled black stove pipe simply screw into the stainless chimney segment that passes through the wall?

oconnor

Minister of Fire

Just make sure you read the instructions. Do whatever the manufacturer of the product says to do - you aren't the first guy to put a chimney thru a basement wall, so it's likely the instructions cover what you need done. Some chimney systems spec for air circulation around the pipe to allow for expansion and to keep the pipe from overcooling in a specific spot and getting creosote buildup. If you were to set it is concrete you could get that effect.

All of the questions you should ask are covered in the sheets you can get from the supplier. If he doesn't have them, chaeck the web, or get your chimney parts from someone who can get you all the instructions and such. Great to have when the insurance company asks.

All of the questions you should ask are covered in the sheets you can get from the supplier. If he doesn't have them, chaeck the web, or get your chimney parts from someone who can get you all the instructions and such. Great to have when the insurance company asks.

I'd like to use a couple of 45 degree elbows to route the chimney so it avoids an overhanging eave. I see they make 45-degree double-walled/insulated Class A elbows, so I take it there's no code requirement that you have to be able to see straight down from the cap all the way to where the chimney meets the horizontal pipe that exits the wall?

oconnor

Minister of Fire

There isn't a specific code requirement to see straight down the flue, but code does require you to follow the manufacturers instructions - most of them prohibit using elbows on external installs.

From your questions, I suspect you haven't gotten the instructions from the manufacturer of the system you are planning. Recommend you do that. It will save you lots of grief.

From your questions, I suspect you haven't gotten the instructions from the manufacturer of the system you are planning. Recommend you do that. It will save you lots of grief.

I've been trying to learn what is allowed/prevented by code in terms of the venting and chimney before spending money on any components. We haven't selected a stove yet. Thanks for that fact about the elbows being forbidden by most manufacturers, though that's not good news for me.

The max angle is 30 deg for an offset elbow on class A. There are elbow kits for this. Or consider penetrating the eave if it is deep enough and go straight up.

The pipe wouldn't really be going "around" the overhang up near the roof; the 30-degree elbow would simply carry the chimney away from the wall about 10-12 inches about 6' above ground-level where the horizontal branch of the Tee emerges from the wall in a room on the first storey, and then a reverse 30-degree elbow would correct the trajectory, bringing the chimney plumb starting at about 7' above ground level. The chimney will be straight up-down for at least 10 feet before it ever reaches the eave.

oconnor

Minister of Fire

The issue isn't about going around things, it's about the flow reduction caused by elbows, and how they can be a spot for creosote buildup. 2 x 45* elbows reduces the effective chimney height by 5 feet, so once you are done, you likely won't have the 15 feet of effective chimney height that is the minimum most stoves require for adequate draft. When used external to a building there is a lot more cooling, so companies usually prohibit the use of them - it doesn't matter why you use it, the just prohibit it. In an internal install, there aren't the same cooling forces to deal with, so less concern about creosote buildup at the elbows, hence they permit them when the chimney is internal to the building.

As for what code requires, code requires that you follow the manufacturers instructions. Factory built chimney systems aren't covered in building code - masonary ones are, as the code describes how to build them. You build a factory built chimney by following the manufacturers instructions.

As for what code requires, code requires that you follow the manufacturers instructions. Factory built chimney systems aren't covered in building code - masonary ones are, as the code describes how to build them. You build a factory built chimney by following the manufacturers instructions.

wagvan said:Thanks for asking this. We are looking at doing something similar. Lots of good info here!

I'm glad to learn that my ignorance is an asset.

Master of Fire, when you write "the manufacturer's instructions" do you mean the manufacturer of the chimney and venting products? Or the stove manufacturer? Do I need to know what stove I want to use before the chimney could be specified? E.g. its BTU/hr rating?

tr123 said:wagvan said:Thanks for asking this. We are looking at doing something similar. Lots of good info here!

I'm glad to learn that my ignorance is an asset.

- Status

- Not open for further replies.

Similar threads

- Replies

- 3

- Views

- 3K

- Replies

- 6

- Views

- 2K

- Replies

- 13

- Views

- 5K

- Replies

- 13

- Views

- 6K