Maine said:

Let me see if I get this right, you are charging your tank with a pex, hx, and also removing heat with a pex hx. Something I was considering with my 750 gal tank.

Steve

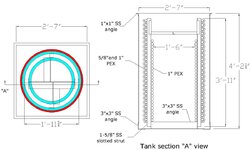

Yes. I installed a separate storage tank (from the furnace storage tank) and made it from type 201 SS. 201 is similar to 304, but much cheaper. The tank walls are 12 ga. and welded at the vertical corners. The bottom horizontal corners of the tank are 3"x3" SS angle and the top lip is supported by 1"x1" SS angle. It holds ~215 gal. We run boiler water through it in parallel 5/8" pex. Parallel to slow the flow and increase heat transfer. 5/8" because that's what I had left over from our floor install. Then I ran well water supplying the LP gas water heater through 300' of 1" pex in the tank.

The 5/8" and 1" are coiled around a SS slotted unistrut support frame I welded up. Both 1" and 5/8" pex are coiled together on the outside of the frame and just the 1" on the inside loop. The pex is attached to the slotted strut frame with tye-wraps rated for 185* and tied 4 to 8 times for each loop. The frame is supported by 3"x3" SS angle at the bottom and 1"x1" SS angle at the top. Hopefully this will last for a few decades.

I'm using the same pump that runs water to my fin and tube coil in my furnace and back to the boiler plate hx. The water flow is controlled by a stat set at 100*. That stat closes a valve when the supply water drops below 100*. That way the preheat tank won't cool off while I'm heating the house from my storage tank and the temps get down low. It's also separately valved with ball valves allowing me to heat the tank directly from my boiler plate hx without heating the rest of the house.

The preheated water then runs into my LP water heater, which has been turned off for 3 days now. We've had more than enough hot water for all our needs (including 2 teenagers). Just checked the tank and it's at 139* at the top, 129* at the bottom.

This will save us $500-$600 per year. The tank materials cost ~$925 including the SS sheet, SS angle, 308L welding wire, 1" and 5/8" pex, pex fittings, black pipe, vales, tye-wraps, plywood and insulation. Less than two year pay back.

If I were to install the loops in the large storage tank the cost would be less, but we might be still use some LP because the large storage tank drops down to 80 degrees at times. Not enough heat to supply all of our hot water. And the length of time we'd have stored water to heat the house with would be less.

I'll send photos and CAD drawings later this evening......