Greetings-

I'm new to the site but have been reading various posts regarding coal burning and coal burning furnaces. We recently moved into a house equipped with a 1981 Tarm 404 wood/coal furnace along side a newer oil burning furnace. Considering the cost of home heating oil, I was anxious to figure out how to burn coal as either a supplement to my oil furnace or an alternative. I read through the operation manual and thought I had a pretty good understanding of how to burn anthracite. I bought several bags and gave it a shot.

Unfortunately, after half a dozen attempts I was growing increasingly frustrated as I could get the fire started okay, but it would end up going out after 2-3 hours. I eventually found a post on this site that complained about similair struggles in his Tarm 500 series, which apparently is an identical model to my 400 series. Someone mentioned that in order to burn coal, a coal conversion kit was required, which consists of a 3 piece coal baffle setup. A few folks mentioned that they had purchased coal baffles from Tarm in NH for around $255. So, I called Tarm and talked to someone in the parts department who told me that the coal baffles are either $255 or $265, depending on if my furnace was a 402 or 404 model. At the time I wasn't sure which model I had, so I went home later that day and determined it was a 404. I called Tarm the next day and this time someone different picked up and told me that whoever had quoted me the price yesterday was wrong, the price is actually around $600 ($200/ea for the upright baffles and $190 for the base plate).

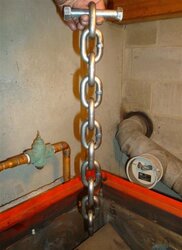

I'm confused because not only was I given a price of $255 during my first call, but I've read several online posts in which Tarm owners said they paid $255 for these baffles before they started burning coal. I'm wondering if these baffles are available from anywhere other than Tarm, such as maybe a Tarm dealer. I know that it's often cheaper in other industries to buy from a dealer than direct from the manufacturer. Secondly, I'm wondering if anyone has attempted fabricating the baffles themselves. I'd be willing to give it a shot if I had some specs or a detailed picture to go off of. The only thing I've been able to find is a pdf bulletin from Tarm with instructions on installing the baffles. The pdf was originally scanned and the image quality is poor.

http://www.woodboilers.com/uploads/public/Coal Baffle Instructions.pdf

I read somewhere that the webmaster a former owner of Tarm, so hopefully this is a good place to ask this question.

Thanks in advance for any help.

Jeff

I'm new to the site but have been reading various posts regarding coal burning and coal burning furnaces. We recently moved into a house equipped with a 1981 Tarm 404 wood/coal furnace along side a newer oil burning furnace. Considering the cost of home heating oil, I was anxious to figure out how to burn coal as either a supplement to my oil furnace or an alternative. I read through the operation manual and thought I had a pretty good understanding of how to burn anthracite. I bought several bags and gave it a shot.

Unfortunately, after half a dozen attempts I was growing increasingly frustrated as I could get the fire started okay, but it would end up going out after 2-3 hours. I eventually found a post on this site that complained about similair struggles in his Tarm 500 series, which apparently is an identical model to my 400 series. Someone mentioned that in order to burn coal, a coal conversion kit was required, which consists of a 3 piece coal baffle setup. A few folks mentioned that they had purchased coal baffles from Tarm in NH for around $255. So, I called Tarm and talked to someone in the parts department who told me that the coal baffles are either $255 or $265, depending on if my furnace was a 402 or 404 model. At the time I wasn't sure which model I had, so I went home later that day and determined it was a 404. I called Tarm the next day and this time someone different picked up and told me that whoever had quoted me the price yesterday was wrong, the price is actually around $600 ($200/ea for the upright baffles and $190 for the base plate).

I'm confused because not only was I given a price of $255 during my first call, but I've read several online posts in which Tarm owners said they paid $255 for these baffles before they started burning coal. I'm wondering if these baffles are available from anywhere other than Tarm, such as maybe a Tarm dealer. I know that it's often cheaper in other industries to buy from a dealer than direct from the manufacturer. Secondly, I'm wondering if anyone has attempted fabricating the baffles themselves. I'd be willing to give it a shot if I had some specs or a detailed picture to go off of. The only thing I've been able to find is a pdf bulletin from Tarm with instructions on installing the baffles. The pdf was originally scanned and the image quality is poor.

http://www.woodboilers.com/uploads/public/Coal Baffle Instructions.pdf

I read somewhere that the webmaster a former owner of Tarm, so hopefully this is a good place to ask this question.

Thanks in advance for any help.

Jeff