Last night I finished setting up my 500 Gallon storage tank and began charging it/opened it to the entire system.

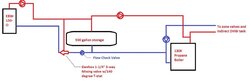

My plumbing is simple:

Supply Side: Wood boiler supply 150' underground to in basement T, one end goes to top of storage tank, the other goes through a 3-speed circ to a T on supply side of my propane boiler.

Return Side: Return on propane boiler T to T on bottom of storage tank, one end goes to tank and the other goes through a Danfoss 3-way mixing valve to the return side of the wood boiler.

- 150' x 1" dia. underground pex each way (from house to wood boiler and back)

- indoor propane boiler has zone valves for upstairs, downstairs, indirect domestic hot water tank (just another zone with mixed output on the potable side) and radiant loop for bathroom

- indoor propane boiler has 1 Grundfos circ pump

- Econoburn Outdoor 150 set to 178 degrees F

I'm not sure if this is the most efficient way to plumb everything, and there are a few questions I'm having since putting the storage online last night:

1) How do I know if my circulators running too fast or too slow? My Econoburn 150 Outdoor model came with a 3-speed Grundfos, so that is set to the middle speed. The Circ on the storage tank is also set to the middle speed. The circulator on my propane boiler is a one-speed Grundfos, so I'll have to look into model to determine speed/flow.

2) The Econoburn Outdoor models are different than the indoor models in that they continuously run the circulator as long as there is power to the boiler. There is a Honeywell aquastat that is set to 190 degrees F on the supply side that shuts the fan off if the temp is 190 or higher. This morning the storage tank felt good and hot, however the indoor boiler showed a temp of 148 degrees F. The outdoor boiler was around 150 degrees F and the fan wasn't on (idling), however the firebox was more than half full of dry white oak splits.

- I'm thinking that the boiler fan should have been cranking and gasifying since my delta T was >20 degrees.

I think I need to set the Honeywell aquastat to something higher than 190 degrees F when running with storage, but does anyone out there have experience with the outdoor econoburn models and storage?

Matt

My plumbing is simple:

Supply Side: Wood boiler supply 150' underground to in basement T, one end goes to top of storage tank, the other goes through a 3-speed circ to a T on supply side of my propane boiler.

Return Side: Return on propane boiler T to T on bottom of storage tank, one end goes to tank and the other goes through a Danfoss 3-way mixing valve to the return side of the wood boiler.

- 150' x 1" dia. underground pex each way (from house to wood boiler and back)

- indoor propane boiler has zone valves for upstairs, downstairs, indirect domestic hot water tank (just another zone with mixed output on the potable side) and radiant loop for bathroom

- indoor propane boiler has 1 Grundfos circ pump

- Econoburn Outdoor 150 set to 178 degrees F

I'm not sure if this is the most efficient way to plumb everything, and there are a few questions I'm having since putting the storage online last night:

1) How do I know if my circulators running too fast or too slow? My Econoburn 150 Outdoor model came with a 3-speed Grundfos, so that is set to the middle speed. The Circ on the storage tank is also set to the middle speed. The circulator on my propane boiler is a one-speed Grundfos, so I'll have to look into model to determine speed/flow.

2) The Econoburn Outdoor models are different than the indoor models in that they continuously run the circulator as long as there is power to the boiler. There is a Honeywell aquastat that is set to 190 degrees F on the supply side that shuts the fan off if the temp is 190 or higher. This morning the storage tank felt good and hot, however the indoor boiler showed a temp of 148 degrees F. The outdoor boiler was around 150 degrees F and the fan wasn't on (idling), however the firebox was more than half full of dry white oak splits.

- I'm thinking that the boiler fan should have been cranking and gasifying since my delta T was >20 degrees.

I think I need to set the Honeywell aquastat to something higher than 190 degrees F when running with storage, but does anyone out there have experience with the outdoor econoburn models and storage?

Matt