jtakeman

Minister of Fire

olddawgsrule said:Results from the test run on high;

Ran for 3 hrs kicking out some nice heat.

225' coming out the blower, 350' read on the firebox.

Now, one thing I had not mentioned is I've had the sides off the unit to watch and read these temps.

Once I out the sides on, out she went!

I mean, 30 seconds after I put the sides on!

I no more than put them on, sighed that this may be over and out it went.

With 350 degrees read off the firebox and this being 1.25 inches from the sensor, it makes sense that it tripped and shut down.

I'm now believing this unit will not run on high with it's current feed/blower settings.

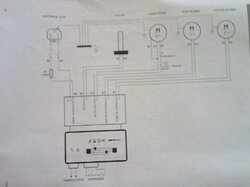

If only I was smart enough to 'hack' into this control panel.

I'm going to take a picture of it and send it over to another forum I belong to to figure out the circuit.

At this point it seems a waste of time to ask USSC since they haven't figured out the exhaust port problem... Andy did!

Post the chip info here too! I have the ability to read them(if there not OTP or locked). Programming it, you would need a coder to have a look at it.