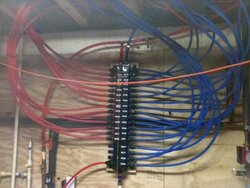

After lots of discussion and pictures over the years of near-boiler plumbing, I realized the most convoluted plumbing that I have is far from the boiler.

This picture shows the outside wall of my boiler room. There are six holes through the wall for connection to storage:

- DHW preheat supply and return

- Main HX coil top and bottom

- Storage refill (there's a few gallons a year of evaporative loss)

- Sensor cables

My two-stage DHW mixing valves are in the picture also. The first (and closest) mixes preheated water with cold water with a target temp of 115. The second mixes the output of the first with hot water from the DHW tank with a target temp of 118.

The water softener adds a bit of extra plumbing all its own.

The clear plastic tube at the top is a sight glass to monitor the storage tank water level.

You can just see the untrimmed window opening at the left - that's where we pass wood into the boiler room. You can see the 1" polyiso board underneath the sheetrock.

Mixed in with all this is a drain for the A/C system and the softener.

It should be obvious from these photos that you'd much rather have me doing controls than plumbing ;-)

This picture shows the outside wall of my boiler room. There are six holes through the wall for connection to storage:

- DHW preheat supply and return

- Main HX coil top and bottom

- Storage refill (there's a few gallons a year of evaporative loss)

- Sensor cables

My two-stage DHW mixing valves are in the picture also. The first (and closest) mixes preheated water with cold water with a target temp of 115. The second mixes the output of the first with hot water from the DHW tank with a target temp of 118.

The water softener adds a bit of extra plumbing all its own.

The clear plastic tube at the top is a sight glass to monitor the storage tank water level.

You can just see the untrimmed window opening at the left - that's where we pass wood into the boiler room. You can see the 1" polyiso board underneath the sheetrock.

Mixed in with all this is a drain for the A/C system and the softener.

It should be obvious from these photos that you'd much rather have me doing controls than plumbing ;-)

hh: LOL

hh: LOL