Here is the latest change to my system. This 50 gallon prototype tank has six 2" FIP ports on the sides and three 3/4' on top. It acts as a hydro-separator tank, instead of a primary loop with closely spaced tees. It also serves as an air eliminator, and a bit of buffer tank.

On the left side it is piped to the EKO boiler. Out the back it pipes to a 500 gallon LP tank storage. Facing out are the connections to my heat and DHW located across the shop.

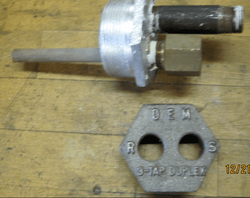

For a nice boiler fitting I use a Duplex bushing with an air vent and a sensor well. This 2" tee on top of the EKO is the high point in the boiler room piping. An additional vent will go on top of the separator tank. The separator tank has a well I built to allow 3 sensors to go into the tank.

Control work in progress as we speak. A dual differential (solar) control runs the boiler pump and the pump from the separator to the 500 gallon. Both pumps run on a variable speed function, as the temperature rises in the boiler the pump speeds up. The pump kicks on when the boiler reaches 150F at that top sensor, off at 140F.

hr

On the left side it is piped to the EKO boiler. Out the back it pipes to a 500 gallon LP tank storage. Facing out are the connections to my heat and DHW located across the shop.

For a nice boiler fitting I use a Duplex bushing with an air vent and a sensor well. This 2" tee on top of the EKO is the high point in the boiler room piping. An additional vent will go on top of the separator tank. The separator tank has a well I built to allow 3 sensors to go into the tank.

Control work in progress as we speak. A dual differential (solar) control runs the boiler pump and the pump from the separator to the 500 gallon. Both pumps run on a variable speed function, as the temperature rises in the boiler the pump speeds up. The pump kicks on when the boiler reaches 150F at that top sensor, off at 140F.

hr