Wow, what a great site. Wealth of knowledge on here.

I was checking out boilers at the Fryeburg fair in Maine. Really liked the look of the Vigas that Mark of AHONA had there. A little background.

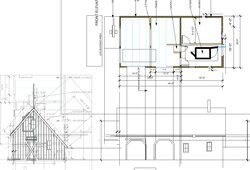

When I originally built my home/wife's photo studio (approx 6k sf heated. Half being finished basement/garage) I had planned to do a Tarm dual fuel with heat storage in the basement. The price initially, and frankly the need for more equipment to get wood scared me off. The nail in the coffin was the increased chance of hurting myself collecting wood. (i'm a pilot, accident means no salary)

So.. i went with a buderus oil boiler. Whole house has radiant. I have a 80 gallon DHW tank that's under the boiler. I've been happy with it's operation. In the dead of winter it will run 16 or 18 hours of the day. I burn, A LOT of oil.

Now the better part. I'm making a portion of the fuel. I make 1200 or so gallons of biodiesel per year. I run some in my mercedes, and I ran it this year at about 65% biodiesel mixed with HHO. Bio cost is around a buck a gallon complete. My complete uneducated guess is that i'm burning 1500 gal of oil a year.

Now, the house is built. I've 70 acres of woods. I've got a 4WD kubota cab tractor. I see enough blow downs (it's wet ground) to have me thinking again about wood. I am thinking a two bay garage close to the back of the house (it's a daylight basement, with the garage around back) would be nice for stuff like the golf cart, the kubota, and all that kinda stuff.

A dedicated building could be built and planned ahead for the boiler and storage. It would be maybe a 50 to 75 food underground run to get back into the garage, with the oil boiler 30 feet from there. (boiler is in the back of the garage, which is under the 1200sf studio)

I don't care about heating the building, but I figure residual heat from the boiler would heat it enough. I go away a lot. But I think the wife would be motivated to not use oil enough to feed the boiler a couple times a day when she walks the dogs.

Thoughts? My guess is that between the building and the boiler I'm gonna spend 35 or 40k. It will need to match the home in a way, but the wife wants it to have 3 different looks, as she is a photographer and we will design the sides to all be different backgrounds. Maybe an old time garage look at the front for kids to have pics taken with their cars.

Anyway, a lot of info in there. Just wondering what I should be thinking next.

PS.. the change of heart over collecting wood. We just got a really good disability policy that would cover me if I got injured. It may sound dumb to some.. but hurt, I can't replace my current salary.

Jason

I was checking out boilers at the Fryeburg fair in Maine. Really liked the look of the Vigas that Mark of AHONA had there. A little background.

When I originally built my home/wife's photo studio (approx 6k sf heated. Half being finished basement/garage) I had planned to do a Tarm dual fuel with heat storage in the basement. The price initially, and frankly the need for more equipment to get wood scared me off. The nail in the coffin was the increased chance of hurting myself collecting wood. (i'm a pilot, accident means no salary)

So.. i went with a buderus oil boiler. Whole house has radiant. I have a 80 gallon DHW tank that's under the boiler. I've been happy with it's operation. In the dead of winter it will run 16 or 18 hours of the day. I burn, A LOT of oil.

Now the better part. I'm making a portion of the fuel. I make 1200 or so gallons of biodiesel per year. I run some in my mercedes, and I ran it this year at about 65% biodiesel mixed with HHO. Bio cost is around a buck a gallon complete. My complete uneducated guess is that i'm burning 1500 gal of oil a year.

Now, the house is built. I've 70 acres of woods. I've got a 4WD kubota cab tractor. I see enough blow downs (it's wet ground) to have me thinking again about wood. I am thinking a two bay garage close to the back of the house (it's a daylight basement, with the garage around back) would be nice for stuff like the golf cart, the kubota, and all that kinda stuff.

A dedicated building could be built and planned ahead for the boiler and storage. It would be maybe a 50 to 75 food underground run to get back into the garage, with the oil boiler 30 feet from there. (boiler is in the back of the garage, which is under the 1200sf studio)

I don't care about heating the building, but I figure residual heat from the boiler would heat it enough. I go away a lot. But I think the wife would be motivated to not use oil enough to feed the boiler a couple times a day when she walks the dogs.

Thoughts? My guess is that between the building and the boiler I'm gonna spend 35 or 40k. It will need to match the home in a way, but the wife wants it to have 3 different looks, as she is a photographer and we will design the sides to all be different backgrounds. Maybe an old time garage look at the front for kids to have pics taken with their cars.

Anyway, a lot of info in there. Just wondering what I should be thinking next.

PS.. the change of heart over collecting wood. We just got a really good disability policy that would cover me if I got injured. It may sound dumb to some.. but hurt, I can't replace my current salary.

Jason

).. It's a buderus tank that my boiler is setting on top of. It's an 80 gallon tank. Overkill, but like many things in my new home.. I overcompensated for the shortcomings of my last house. Just my wife and I and the dogs, so HW is never an issue.

).. It's a buderus tank that my boiler is setting on top of. It's an 80 gallon tank. Overkill, but like many things in my new home.. I overcompensated for the shortcomings of my last house. Just my wife and I and the dogs, so HW is never an issue.