Hello All,

almost done now, we are staring electrical work today.

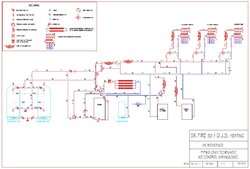

These are some pix(post 1 & 2) of the plbg layouts we finished last week, but started in June..slow go..life takes precedence.

All naked for now, will all be wrapped upon final testing and multiple firings before heating season.

Thank you to ALL IN THIS ROOM...ESPECIALLY RENE @ Tarm, HEATERMAN, JIM IN PA, DUANE, RUSS, KARL K & his brother AND ALL THE OTHER INVALUABLE BOILER ROOM "WRENCHES & BRAINS".

I LEARNED MORE FROM YOU THAN I CAN EVER ACCOUNT AND HOPE TO ADEQUATELY THANK FOR.

Also if it wasn't for Doug and DJS Heating & Brian form TE....this would look...well it wouldn't look like this.

I finally decided on this set up after a long and heavily calculated progress(financial & design/application standpoints).

My original plans were Garn, but certain aspects and values were prohibitive in the end.

Nothing to do with Garn value & quality, just tax, building , trench and location/system issues.

(..as a result, also had to re cut lengths for 6 cords from 26" average down to 13"-21").

More to follow.

Scott

ps: Buderus boiler and indirect are piped for temp, so the wife does not crucify me on the front yard..she may yet ...but the kids are happy...

almost done now, we are staring electrical work today.

These are some pix(post 1 & 2) of the plbg layouts we finished last week, but started in June..slow go..life takes precedence.

All naked for now, will all be wrapped upon final testing and multiple firings before heating season.

Thank you to ALL IN THIS ROOM...ESPECIALLY RENE @ Tarm, HEATERMAN, JIM IN PA, DUANE, RUSS, KARL K & his brother AND ALL THE OTHER INVALUABLE BOILER ROOM "WRENCHES & BRAINS".

I LEARNED MORE FROM YOU THAN I CAN EVER ACCOUNT AND HOPE TO ADEQUATELY THANK FOR.

Also if it wasn't for Doug and DJS Heating & Brian form TE....this would look...well it wouldn't look like this.

I finally decided on this set up after a long and heavily calculated progress(financial & design/application standpoints).

My original plans were Garn, but certain aspects and values were prohibitive in the end.

Nothing to do with Garn value & quality, just tax, building , trench and location/system issues.

(..as a result, also had to re cut lengths for 6 cords from 26" average down to 13"-21").

More to follow.

Scott

ps: Buderus boiler and indirect are piped for temp, so the wife does not crucify me on the front yard..she may yet ...but the kids are happy...

That man was a killer

That man was a killer