Hello to everyone. I have enjoyed reading all about your experiences with boilers. Because of your wealth of experience, I would like to ask you for some advice.

I currently live in south central PA, in a 100+ year old farmhouse with some insulation (I know it’s there because I see it blow across the floor when it is windy). I have been heating the last 15 years with a Tarm Excel 2000 with oil backup. The house is roughly 3600 sq.ft. and I burn about 5 to 6 cords of hardwood, along with 100-200 gallons of oil per year (If I use only oil, I burn about 50 to 60 gallons a week). I have baseboard heat, set at 68 degrees, on all four floors and we also use the system to heat our DHW . The Tarm has been a great setup, but after 15 years the secondary combustion chamber is starting to show its age, my wife is sick of the dust in the house and I am tired of loading wood in the basement (especially since the kids are away at school). I was considering going with the GARN, Frohling, or the E-Classic 2300, but after reading countless threads, and doing a lot of research, I am going with the GARN.

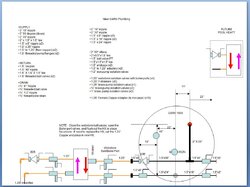

I am planning on putting the GARN in a woodshed that I am building this fall. I am timber framing an 18 X 30’ woodshed about 100’ from the house. I figure with this size I can easily store enough wood, have room for the boiler, and still have room to move around. I would like to keep the Tarm in my basement as the backup oil burning boiler, and pipe the GARN into the existing setup.

Would you have any specific recommendations for my situation? I have already made a mental plan for how I would like to set this up, but before I put it down on paper, I would love to hear your thoughts.

Any advice, tips, or warnings you can give me would be greatly appreciated.

Thank you....Bob

I currently live in south central PA, in a 100+ year old farmhouse with some insulation (I know it’s there because I see it blow across the floor when it is windy). I have been heating the last 15 years with a Tarm Excel 2000 with oil backup. The house is roughly 3600 sq.ft. and I burn about 5 to 6 cords of hardwood, along with 100-200 gallons of oil per year (If I use only oil, I burn about 50 to 60 gallons a week). I have baseboard heat, set at 68 degrees, on all four floors and we also use the system to heat our DHW . The Tarm has been a great setup, but after 15 years the secondary combustion chamber is starting to show its age, my wife is sick of the dust in the house and I am tired of loading wood in the basement (especially since the kids are away at school). I was considering going with the GARN, Frohling, or the E-Classic 2300, but after reading countless threads, and doing a lot of research, I am going with the GARN.

I am planning on putting the GARN in a woodshed that I am building this fall. I am timber framing an 18 X 30’ woodshed about 100’ from the house. I figure with this size I can easily store enough wood, have room for the boiler, and still have room to move around. I would like to keep the Tarm in my basement as the backup oil burning boiler, and pipe the GARN into the existing setup.

Would you have any specific recommendations for my situation? I have already made a mental plan for how I would like to set this up, but before I put it down on paper, I would love to hear your thoughts.

Any advice, tips, or warnings you can give me would be greatly appreciated.

Thank you....Bob