woodchip

Minister of Fire

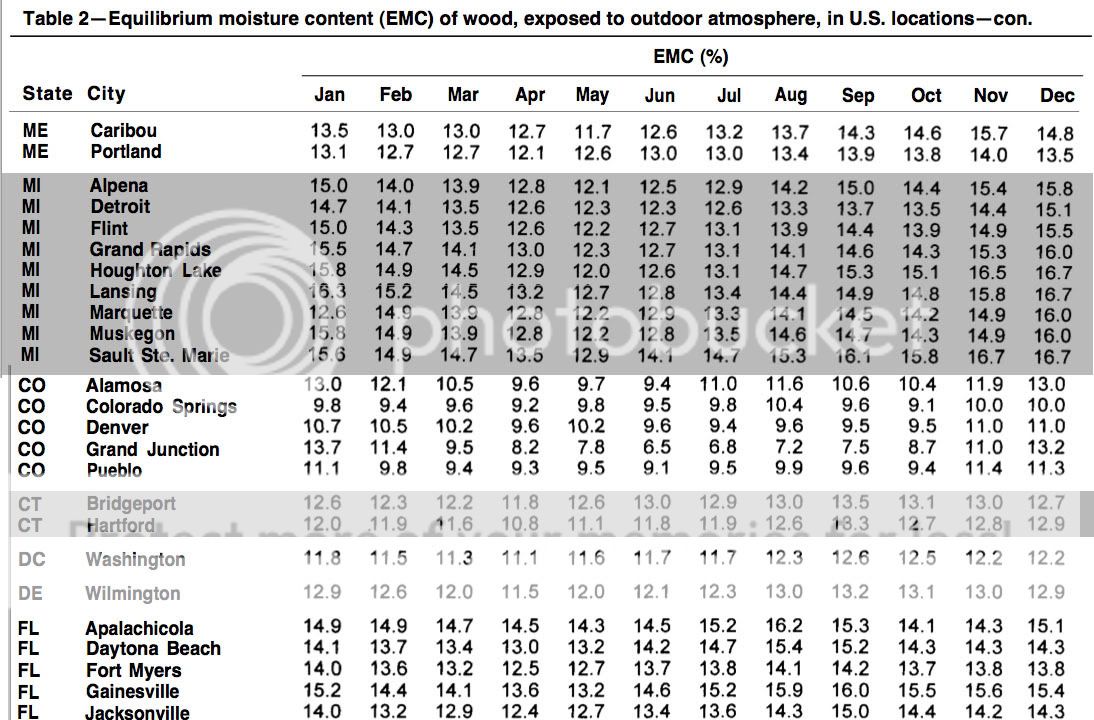

skyline said:From the graphs what should be clear is that the fresh "live" c/s/s wood will dry quickly at first, practically no matter the conditions. See Portland's weather last April-June if you have any doubts.

Thanks for this follow up post, I'm following this with a lot of interest.

Taking this thought of fast initial seasoning no matter what the conditions, I'm going to put my thoughts here if I may.

The rapid loss of the first part of moisture occurs because the wood is damper than most dry or humid days, and will also give up more moisture while the sapways (is that the right term) are more open after cutting.

If this is the case, cutting in the early fall will allow seasoning to take pace during the fall/winter while the split is still relatively wet, and will continue to season well the following Summer when the humidity should be lower and seasoning conditions better.

On that basis, with good wind flow and a dryish Summer, most wood would dry well with in one year of cutting where you are.

Now for the acid test. Have you any plans to burn your test wood against some which has been seasoning for, say, 3 years ???

), but now we can actually base it on factual info. No more guestimating WHY. And it also backs up the often repeated mantra of "split, stack, season for two years and you should be good to go". Could it happen sooner - sure. But that covers the bases as about complete as one can while only using a single statement.

), but now we can actually base it on factual info. No more guestimating WHY. And it also backs up the often repeated mantra of "split, stack, season for two years and you should be good to go". Could it happen sooner - sure. But that covers the bases as about complete as one can while only using a single statement.