Hello everyone!

So I have the small Englander pellet stove and while it works great I've been having problems this year. I've already burned through over 1.5 tons of pellets and it seems to burn dirty. It was made 2/08 and this will be the 4th season with it. I've never replaced the burn pot gasket so I have one on order and hope this helps with the dirty burn.

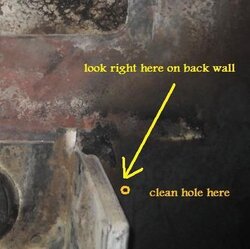

Also, while give it a thorough vacuuming today we noticed that behind the impingement plate there is a crack and it is bowed out. Also the impingement plate fits a bit loose and leans forward some. Is this crack going to be a problem? Is there a way to repair it? I should think I can get more than 4 seasons out of this stove!! HELP

Here's a picture of what I'm talking about.

So I have the small Englander pellet stove and while it works great I've been having problems this year. I've already burned through over 1.5 tons of pellets and it seems to burn dirty. It was made 2/08 and this will be the 4th season with it. I've never replaced the burn pot gasket so I have one on order and hope this helps with the dirty burn.

Also, while give it a thorough vacuuming today we noticed that behind the impingement plate there is a crack and it is bowed out. Also the impingement plate fits a bit loose and leans forward some. Is this crack going to be a problem? Is there a way to repair it? I should think I can get more than 4 seasons out of this stove!! HELP

Here's a picture of what I'm talking about.