I was looking up some things about exemptions at the EPA site. Saw lots of stoves with this 35:1 air ratio. Didn't see a definition of that. I can see the EPA is soon to close the gaps for all wood burning appliances made, even pizza ovens and chimineas. But anyway, would like to know why stoves with this 35:1 ratio are currently exempt.

35:1 Ratio - Meaning?

- Thread starter REF1

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

34:1 is hydrogen. I could read that page all week and not figure out everything it is stating. But you're probably right about the stoichiometry.

thechimneysweep

Minister of Fire

The way it was explained to me, 35:1 is about the ratio of air to fuel in a given fire. When wood smoke pollutants were first being studied, it was found that particulate emissions increased dramatically in the controlled-airflow environment of the airtight stoves of the day. In other words, a smoldering fire is a smokey fire. Open fires were seen as less polluting, as the free availability of air to the fire made for a more complete burn, and the unburned particulates were spread out over the much larger volume of airflow out the chimney.

Take an open fireplace with a 5 cu.ft. (100 lb.) load of wood. The minimum airflow through the system required to maintain a 35:1 air/fuel ratio would be about 175 cu.ft./minute, which is a relatively low flow rate for a fireplace flue ( I have seen numbers as high as 400 cu.ft./minute for a briskly burning fire). With that much airflow, more of the wood solids would be consumed at the source by the resulting tall, hot flames, while the remaining unburned particles would enter the airshed in a very low concentration due to the vast volume of air in the mix.

So, to qualify for exemption under the 35:1 rule, a wood stove with a 2 cu.ft. (40 lb.) load would need a constant airflow rate through the firebox of at least 70 cu.ft./minute. This does not describe high-efficiency airtight stoves, which typically have an airlow rate somewhere around 25 CFM or less. In an airtight, some form of secondary combustion is necessary to keep the particulate density of the exhaust at an acceptable level.

Take an open fireplace with a 5 cu.ft. (100 lb.) load of wood. The minimum airflow through the system required to maintain a 35:1 air/fuel ratio would be about 175 cu.ft./minute, which is a relatively low flow rate for a fireplace flue ( I have seen numbers as high as 400 cu.ft./minute for a briskly burning fire). With that much airflow, more of the wood solids would be consumed at the source by the resulting tall, hot flames, while the remaining unburned particles would enter the airshed in a very low concentration due to the vast volume of air in the mix.

So, to qualify for exemption under the 35:1 rule, a wood stove with a 2 cu.ft. (40 lb.) load would need a constant airflow rate through the firebox of at least 70 cu.ft./minute. This does not describe high-efficiency airtight stoves, which typically have an airlow rate somewhere around 25 CFM or less. In an airtight, some form of secondary combustion is necessary to keep the particulate density of the exhaust at an acceptable level.

thechimneysweep

Minister of Fire

Now here's an example of how hearth.com has grown over the last couple of years. When I signed on there was no hearth wiki, and I still don't think to go there. So, assuming we started our replies at about the same time, BeGreen was able to beat my response time by about 27 minutes. And provide better data to boot. Sometimes I feel like a dinosaur in the Information Age...

Battenkiller

Minister of Fire

Clearly explained or not, the information is not correct.

The air:fuel ratios are always based on mass, not volume - a huge difference. Specifically, in this case, grams of dry air per gram of dry wood burned.

Using volumetric measurements to determine air:fuel ratios doesn't even make sense. Picture the inside of your car engine. The stoichiometric (fancy word for balanced chemical reaction) air:fuel ratio of gasoline during complete combustion is somewhere around 15:1. Air:fuel ratios is excess of this number are considered lean, while those that are lower indicate a rich mixture. But does it make a difference how many cubic inches of displacement that particular cylinder has, or how rapidly that cylinder is cycled?

Wood needs a lot less air than does gasoline to achieve complete combustion. Roughly, six pounds of air to one pound dry wood. Due to much less efficient mixing of intake air and fuel gases compared to an internal combustion engine, stoves need air in great excess of the stoichiometric amount. Airtight stoves deliver between 1.5 to 3 times that much, so there is always a lot of excess air inside any efficiently burning stove. A wood burning system that provides 3 times the amount of air (by weight) needed for complete combustion gives an 18:1 ratio of fuel to air. That is about half the air need to achieve a 35:1 ratio, so these stoves are not exempt from the EPA standard. That is how the determination is made, and not at all on firebox volume.

Another small but significant quibble. Particulate density inside your system is not the only indicator of the amount of smoke pollution a stove produces per unit time (which is what the stove is being tested for). It all ends up in the atmosphere, so it is the total amount of particulate matter per hour that the stove produces that is measured, not the smoke density. These two things can be highly correlated in practice, but there is no direct physical relationship between them. A stove can produce copious amounts of smoke, and yet the smoke density can be low due to draft and flue design (for example, an excessively tall and oversize flue chimney), and the opposite can also occur, where a stove burns fairly clean, but low flue temps and poor draft can lead to relatively longer residence times and, therefore, increased smoke density. No matter, once it escapes the top of the stack it is all the same amount of pollution.

What is important and is often overlooked is how all these variables can add up to problems in certain applications. Just because your stove passes the EPA standard doesn't mean you can burn it any old way and get good clean burns with lots of heat delivered into the room. Non-cat heaters can make up to 7.5 grams of particulate matter per hour and still pass.

Since these devices are tested under somewhat ideal conditions, the very least a 24/7 burner will produce is about 85 pounds of particulate matter in a 7 month burning season. If you add in just the startup burn (the smokey "pre-load" part the EPA doesn't test for), you are probably up to well over over 100 pounds of particulate matter. Now consider all the days that you can't buy a decent burn for no apparent reason... even more smoke produced. In all, there is enough particulate matter going up the flue of even the most efficient stoves to produce dozens of gallons of creosote, all of it having at least the potential for deposition onto the chimney walls if the flue temps and residence times are low enough.

That's why I advocate burning hot and learning to live with whatever heat goes up the flue. Stove top temp is irrelevant. If you have the proper flue gas temp, you are burning correctly, even when using less than ideal wood as your fuel. Hot flue temps = better, cleaner burns, and increased safety in the long run. Remember, burning clean is the goal of modern stove designs. Increased efficiency (if it exists at all) is just a by-product of a stove designed to burn cleaner.

The air:fuel ratios are always based on mass, not volume - a huge difference. Specifically, in this case, grams of dry air per gram of dry wood burned.

Using volumetric measurements to determine air:fuel ratios doesn't even make sense. Picture the inside of your car engine. The stoichiometric (fancy word for balanced chemical reaction) air:fuel ratio of gasoline during complete combustion is somewhere around 15:1. Air:fuel ratios is excess of this number are considered lean, while those that are lower indicate a rich mixture. But does it make a difference how many cubic inches of displacement that particular cylinder has, or how rapidly that cylinder is cycled?

Wood needs a lot less air than does gasoline to achieve complete combustion. Roughly, six pounds of air to one pound dry wood. Due to much less efficient mixing of intake air and fuel gases compared to an internal combustion engine, stoves need air in great excess of the stoichiometric amount. Airtight stoves deliver between 1.5 to 3 times that much, so there is always a lot of excess air inside any efficiently burning stove. A wood burning system that provides 3 times the amount of air (by weight) needed for complete combustion gives an 18:1 ratio of fuel to air. That is about half the air need to achieve a 35:1 ratio, so these stoves are not exempt from the EPA standard. That is how the determination is made, and not at all on firebox volume.

Another small but significant quibble. Particulate density inside your system is not the only indicator of the amount of smoke pollution a stove produces per unit time (which is what the stove is being tested for). It all ends up in the atmosphere, so it is the total amount of particulate matter per hour that the stove produces that is measured, not the smoke density. These two things can be highly correlated in practice, but there is no direct physical relationship between them. A stove can produce copious amounts of smoke, and yet the smoke density can be low due to draft and flue design (for example, an excessively tall and oversize flue chimney), and the opposite can also occur, where a stove burns fairly clean, but low flue temps and poor draft can lead to relatively longer residence times and, therefore, increased smoke density. No matter, once it escapes the top of the stack it is all the same amount of pollution.

What is important and is often overlooked is how all these variables can add up to problems in certain applications. Just because your stove passes the EPA standard doesn't mean you can burn it any old way and get good clean burns with lots of heat delivered into the room. Non-cat heaters can make up to 7.5 grams of particulate matter per hour and still pass.

Since these devices are tested under somewhat ideal conditions, the very least a 24/7 burner will produce is about 85 pounds of particulate matter in a 7 month burning season. If you add in just the startup burn (the smokey "pre-load" part the EPA doesn't test for), you are probably up to well over over 100 pounds of particulate matter. Now consider all the days that you can't buy a decent burn for no apparent reason... even more smoke produced. In all, there is enough particulate matter going up the flue of even the most efficient stoves to produce dozens of gallons of creosote, all of it having at least the potential for deposition onto the chimney walls if the flue temps and residence times are low enough.

That's why I advocate burning hot and learning to live with whatever heat goes up the flue. Stove top temp is irrelevant. If you have the proper flue gas temp, you are burning correctly, even when using less than ideal wood as your fuel. Hot flue temps = better, cleaner burns, and increased safety in the long run. Remember, burning clean is the goal of modern stove designs. Increased efficiency (if it exists at all) is just a by-product of a stove designed to burn cleaner.

Fsappo

Minister of Fire

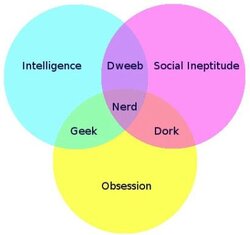

Batten Killer is a nerd.

Great post though. Reading information like that a few times always helps me explain combustion to clients with more confidence

Great post though. Reading information like that a few times always helps me explain combustion to clients with more confidence

Battenkiller

Minister of Fire

Franks said:Batten Killer is a nerd.

:lol:

Not sure you nailed it right, though. I may be closer to a dork than a nerd. :roll:

Attachments

Fsappo

Minister of Fire

Battenkiller said:Franks said:Batten Killer is a nerd.

:lol:

Not sure you nailed it right, though. I may be closer to a dork than a nerd. :roll:

Lovely, now i gottas do the test and see where I fit in

Fsappo

Minister of Fire

Battenkiller

Minister of Fire

Franks said:Just look at the circles, I guess I'm a Dork as well, but I new maintain Batten is a dweeb

I can live with "dweeb". At least I'm not all in the pink circle of pure social ineptitude.

I was looking over the EPA exemption list to see if my dream stove - the small Vogelzang box stove - passed the 35:1 exemption measurement. No, it turns out, but it does pass the >5kg/hour burn rate test. All you guys paying $3K for fancy new EPA rated burners, and I'm going to squeak past the regs with a classic design from the past for about a tenth the price. 96,000 BTU/hr! How could I go wrong? ;-)

No wonder the used ones on Craig's list are always two-toned.

cycloxer

Minister of Fire

Danno77

Minister of Fire

- Status

- Not open for further replies.

Similar threads

- Replies

- 5

- Views

- 723

- Replies

- 20

- Views

- 736

- Replies

- 9

- Views

- 858

- Replies

- 12

- Views

- 1K