OK, I've "bit the bullet" (in the interest of doing things well, once, not cheapskating and re-doing later, which always seems to cost more in the long run) and have, on hand:

1200 gallons of unpressurized (6x6 ft wide x 5 ft high) 409 stainless storage, with a stratification baffle in progress that will keep the hot water going into and coming out of the top of the tank, and the cold water into/out of the bottom

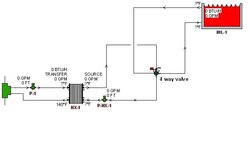

A GEA/ FlatPlate 5x12x70 plate HX

a set of Wilo 3 speed circs, iron for the pressurized side between my primary/ secondary and the the plate HX, and bronze for the open/ tank side

a Caleffi DirtCal to catch crud on the open tank side

a pair of Tekmar 722 1.25 inch 4 way valves to use to swap directions of flow on both sides of the plate HX, so as to be able to attain and keep maximum efficiency of heat transfer across the plate HX

and

both hot and cold to/from the tank to the plate HX will come out of the _bottom_ of the tank, so as to maintain maximum feasible gravity head across the "open" circulator in hopes of minimizing risk of cavitation as the tank gets to max temps

in a perfect world, where I was far further ahead on my install, I'd enjoy figuring out all the nuances of the plumbing diagrams for maintaining counterflow across both sides of the plate HX, under all scenarios, all on my own-

but- between the schedule of the day job, weather patterns, and other things I need to move on with with the install- I am WAY behind where I'd hoped and aimed to be, so,

PLEASE- someone/ everyone give me some hints/diagrams on the plumbing and valving configurations with the 4-ways to maintain counterflow both when the boiler is the heat source and the tank is the heat sink, and when the boiler'sfire is out and the tank is the heat source and the house is the heat sink. [recall that the boiler, tank, and house are all in a loop on aprimary secondary arrangement, and that the use of the Taco twin tees makes all secondary circuits happily bi-directional, unlike normal "closely spaced tees")

Thanks

1200 gallons of unpressurized (6x6 ft wide x 5 ft high) 409 stainless storage, with a stratification baffle in progress that will keep the hot water going into and coming out of the top of the tank, and the cold water into/out of the bottom

A GEA/ FlatPlate 5x12x70 plate HX

a set of Wilo 3 speed circs, iron for the pressurized side between my primary/ secondary and the the plate HX, and bronze for the open/ tank side

a Caleffi DirtCal to catch crud on the open tank side

a pair of Tekmar 722 1.25 inch 4 way valves to use to swap directions of flow on both sides of the plate HX, so as to be able to attain and keep maximum efficiency of heat transfer across the plate HX

and

both hot and cold to/from the tank to the plate HX will come out of the _bottom_ of the tank, so as to maintain maximum feasible gravity head across the "open" circulator in hopes of minimizing risk of cavitation as the tank gets to max temps

in a perfect world, where I was far further ahead on my install, I'd enjoy figuring out all the nuances of the plumbing diagrams for maintaining counterflow across both sides of the plate HX, under all scenarios, all on my own-

but- between the schedule of the day job, weather patterns, and other things I need to move on with with the install- I am WAY behind where I'd hoped and aimed to be, so,

PLEASE- someone/ everyone give me some hints/diagrams on the plumbing and valving configurations with the 4-ways to maintain counterflow both when the boiler is the heat source and the tank is the heat sink, and when the boiler'sfire is out and the tank is the heat source and the house is the heat sink. [recall that the boiler, tank, and house are all in a loop on aprimary secondary arrangement, and that the use of the Taco twin tees makes all secondary circuits happily bi-directional, unlike normal "closely spaced tees")

Thanks