Hello All-

If we all had 2 to 5k laying around hot water storage would be a breeze. That combined with the freight of some of these solutions to remote locations like mine, makes the decision a difficult one.

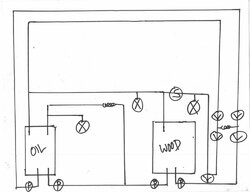

So I'm considering a project in phases. My end goal is to add 400 gallons of storage so as cash becomes available I simply add another pair of drums until things balance out. After surfing the web I think that a collection of 55 gallon steel drums plumbed in parallel will work quite nicely. Each drum will need a anti-corrosion rod but I think I can even keep it pressurized.

Questions and opinions are welcome....

What kind of pressure do I need for heating and can I find a closed steel drum to meet that spec? 50PSI Before it blows?

Does the storage need an expansion tank?

Has anyone used this method before and suffered a dismal failure?

Is their a major concept I'm missing here?

Ed Hills

Tarm MB 55

1940 something coal boiler, converted to steam then oil

My First Winter on Wood.

If we all had 2 to 5k laying around hot water storage would be a breeze. That combined with the freight of some of these solutions to remote locations like mine, makes the decision a difficult one.

So I'm considering a project in phases. My end goal is to add 400 gallons of storage so as cash becomes available I simply add another pair of drums until things balance out. After surfing the web I think that a collection of 55 gallon steel drums plumbed in parallel will work quite nicely. Each drum will need a anti-corrosion rod but I think I can even keep it pressurized.

Questions and opinions are welcome....

What kind of pressure do I need for heating and can I find a closed steel drum to meet that spec? 50PSI Before it blows?

Does the storage need an expansion tank?

Has anyone used this method before and suffered a dismal failure?

Is their a major concept I'm missing here?

Ed Hills

Tarm MB 55

1940 something coal boiler, converted to steam then oil

My First Winter on Wood.