Long story short, I ordered Quad Adventure III, 630# and the dealer didn't seem to be very keen on getting that installed despite my offers to help. So I ended up doing it myself. Just me and my tractor ; )

I rented a truck and dealer was kind enough to forklift it in. Here we just arrived home, it's a monster crate. Labeled 630# of dead weight.

Here is my buddy doing all the hard work:

This is where the stove will need to go in. We got this house earlier this spring so there has been lots of projects to get it in living condition. Those stairs are rough shape. They lead to the top floor where the hearth is.

Since there is no way to lift that stove even with a couple of people (there is, but not very pleasant one) I made a quick roller cart. The wheels are from HF, rated at 300#

Instead of dragging it by the stairs, I figured to lift the whole thing to the top level, requiring temporarily taking out the railing (I put it back together after ; )

Because top stairs aren't level with the main floor (i.e. there is one extra step into the house) I screwed together a ramp from scraps:

Now to the fun part, lifting the stove from the grate foundation to the dolly:

... but first you need to unscrew the lag bolts holding it to the crate bottom:

and the hidden ones ; )

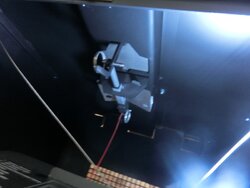

I got Kubota L25 to help:

In order to lift it to the top of the stairs, I'm lifting from under. The height is about over 6', so tractor can't lift from the top and the higher you life, the less lifting force you got. The stove is top heavy, and base is narrow, so I bound foundation of it to the forks. That was a really really good idea.

I got the stove to the top, not as square as I wanted to. The ground is not even and there is a hill behind me, so moving around with forks swaying and top heavy, very expensive stove on top was the scariest part of the whole operation. Hence there are no photos of it hanging from the tractor.

Once the stop was on top, I screwed in some boards just in case the dolly wanted to roll off the 3' square ramp. Once this thing wants to roll, there is not a whole lot that can do.

Well, that was easy to roll it into the house, but placing it onto the hearth wasn't picknick. First I had to remove it from the dolly.

Then place it onto rolling "pipes" ... one of those pipes it's not really a pipe ... guess what it is ; )

With stove this heavy you may as well forget sliding it. Letting gravity do it's work is the only way. I tried those easy sliders, even lubed them with water. Not a whole much luck. I'm 220# and there is little I can do to rock or nudge it side to side.

Well, the only sweat broken is during the lift of the stove and doing some prep work like building the dolly and the ramp. It took me an afternoon of work, no cussing. If you got plan together and you are willing to take time, good plan is better than several sweaty guys trying to muscle 630# in.

I rented a truck and dealer was kind enough to forklift it in. Here we just arrived home, it's a monster crate. Labeled 630# of dead weight.

Here is my buddy doing all the hard work:

This is where the stove will need to go in. We got this house earlier this spring so there has been lots of projects to get it in living condition. Those stairs are rough shape. They lead to the top floor where the hearth is.

Since there is no way to lift that stove even with a couple of people (there is, but not very pleasant one) I made a quick roller cart. The wheels are from HF, rated at 300#

Instead of dragging it by the stairs, I figured to lift the whole thing to the top level, requiring temporarily taking out the railing (I put it back together after ; )

Because top stairs aren't level with the main floor (i.e. there is one extra step into the house) I screwed together a ramp from scraps:

Now to the fun part, lifting the stove from the grate foundation to the dolly:

... but first you need to unscrew the lag bolts holding it to the crate bottom:

and the hidden ones ; )

I got Kubota L25 to help:

In order to lift it to the top of the stairs, I'm lifting from under. The height is about over 6', so tractor can't lift from the top and the higher you life, the less lifting force you got. The stove is top heavy, and base is narrow, so I bound foundation of it to the forks. That was a really really good idea.

I got the stove to the top, not as square as I wanted to. The ground is not even and there is a hill behind me, so moving around with forks swaying and top heavy, very expensive stove on top was the scariest part of the whole operation. Hence there are no photos of it hanging from the tractor.

Once the stop was on top, I screwed in some boards just in case the dolly wanted to roll off the 3' square ramp. Once this thing wants to roll, there is not a whole lot that can do.

Well, that was easy to roll it into the house, but placing it onto the hearth wasn't picknick. First I had to remove it from the dolly.

Then place it onto rolling "pipes" ... one of those pipes it's not really a pipe ... guess what it is ; )

With stove this heavy you may as well forget sliding it. Letting gravity do it's work is the only way. I tried those easy sliders, even lubed them with water. Not a whole much luck. I'm 220# and there is little I can do to rock or nudge it side to side.

Well, the only sweat broken is during the lift of the stove and doing some prep work like building the dolly and the ramp. It took me an afternoon of work, no cussing. If you got plan together and you are willing to take time, good plan is better than several sweaty guys trying to muscle 630# in.