I took some pictures of my grandfather's fireplace a couple of weeks ago. His house was built right around 1800 and supposedly the bricks were handmade on the property in NH. I thought you guys might like to see a couple pics of just another old fireplace

I'm curious if the bricks were really hand made. Is there any way to tell whether or not they were based on these pictures?

A closer view of the bake oven.

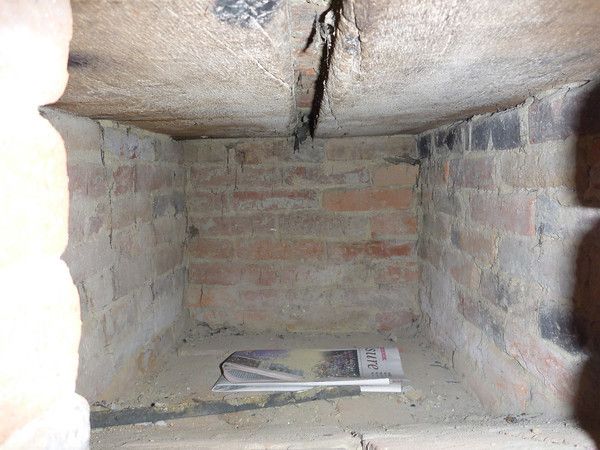

....And here is one of the inside of the bake oven as well as the flu going up the chimney, the flu is directly behind (and of course above) the door, so in other words it is in the very front of the bake oven, is this typical?

I'm assuming the section directly underneath the bake oven was used for wood storage or some other type of storage? These pics are of the lower steel door and inside the compartment. Notice the wood planks supporting the bricks to the base of the bake oven above.

I should have checked the date on that newspaper

I have always loved this fireplace and admire it every time I visit my grandfather. He used to have an old woodstove hooked up to it but he removed it since he doesn't burn wood anymore. It is currently accumulating rust and dust up in the barn, I'm hoping to have it restored one day.

I'm curious if the bricks were really hand made. Is there any way to tell whether or not they were based on these pictures?

A closer view of the bake oven.

....And here is one of the inside of the bake oven as well as the flu going up the chimney, the flu is directly behind (and of course above) the door, so in other words it is in the very front of the bake oven, is this typical?

I'm assuming the section directly underneath the bake oven was used for wood storage or some other type of storage? These pics are of the lower steel door and inside the compartment. Notice the wood planks supporting the bricks to the base of the bake oven above.

I should have checked the date on that newspaper

I have always loved this fireplace and admire it every time I visit my grandfather. He used to have an old woodstove hooked up to it but he removed it since he doesn't burn wood anymore. It is currently accumulating rust and dust up in the barn, I'm hoping to have it restored one day.