I have a few questions about my brand new ideal steel. I will preface this with a bit of background. I have a new to me house, with a brick with clay liner interior chimney. I am going to reline the chimney(insulated ss) this summer. About 19' of run to the top.

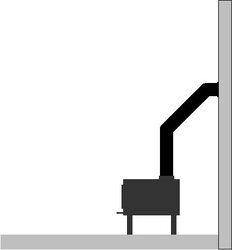

I just purchased a new ideal steel stove and installed it this past week, and have had jus a few fires in it. It has a soapstone liner and no ash pan. I am currently using 3 feet of single wall pipe and an elbow to connect into the masonry chimney. I am in Maine, and we are now getting into some milder temps of 30s and 40s during the day. I am not sure if some of what I am seeing is draft related issues that the liner and colder temps will later fix (I hope).

I have noticed that the stove seems real slow to get started. When I get the kindling going with the door cracked, as soon as I close the door, it really slows the fire quite a bit, even with the air all the way open. Is this what others are seeing as well? Then it seems like the stove takes quite a while to get up to temp, and hangs between 300-400 for a long time. Once it does get to temp it runs great, with nice secondary's and good burn times. What is a good stovetop temp for this stove to cruise at? 500?

Also the stove seems real dark a lot of the time with no real flames showing, but real good temps like 500 on the top. Am I running this correctly, or am I shutting it down to much?

Today I noticed that the soapstone liner has taken on a black and brown covering, with a little bit of the dreaded shiny black as well. Is this normal? Makes me wonder what my chimney is looking like? I have had not cat (Lopi) stoves before and the firebrick inside always stayed clean, and I am not sure if this is normal for a cat stove?

I also am struggling with the thought of not knowing if the cat is running or not. I always wait until the stovepipe is at least 300 before I engage the cat. Once I engage it the pipe temp will drop some, but the stove top temp will hover around 300-400 and I just don't know if the cat is light or not. Any one else see this?

This is my first cat stove, and all new ground for me. I know this is supposed to be a great stove, and I just don't want to screw it up! Any help much appreciated. Thanks.

I just purchased a new ideal steel stove and installed it this past week, and have had jus a few fires in it. It has a soapstone liner and no ash pan. I am currently using 3 feet of single wall pipe and an elbow to connect into the masonry chimney. I am in Maine, and we are now getting into some milder temps of 30s and 40s during the day. I am not sure if some of what I am seeing is draft related issues that the liner and colder temps will later fix (I hope).

I have noticed that the stove seems real slow to get started. When I get the kindling going with the door cracked, as soon as I close the door, it really slows the fire quite a bit, even with the air all the way open. Is this what others are seeing as well? Then it seems like the stove takes quite a while to get up to temp, and hangs between 300-400 for a long time. Once it does get to temp it runs great, with nice secondary's and good burn times. What is a good stovetop temp for this stove to cruise at? 500?

Also the stove seems real dark a lot of the time with no real flames showing, but real good temps like 500 on the top. Am I running this correctly, or am I shutting it down to much?

Today I noticed that the soapstone liner has taken on a black and brown covering, with a little bit of the dreaded shiny black as well. Is this normal? Makes me wonder what my chimney is looking like? I have had not cat (Lopi) stoves before and the firebrick inside always stayed clean, and I am not sure if this is normal for a cat stove?

I also am struggling with the thought of not knowing if the cat is running or not. I always wait until the stovepipe is at least 300 before I engage the cat. Once I engage it the pipe temp will drop some, but the stove top temp will hover around 300-400 and I just don't know if the cat is light or not. Any one else see this?

This is my first cat stove, and all new ground for me. I know this is supposed to be a great stove, and I just don't want to screw it up! Any help much appreciated. Thanks.

before I notice a reduction and even then the fire takes off pretty quickly. I just have to be mindful of smoke spillage until the flue is warmed up. That is with a straight up 20 ft chimney and good dry kindling.

before I notice a reduction and even then the fire takes off pretty quickly. I just have to be mindful of smoke spillage until the flue is warmed up. That is with a straight up 20 ft chimney and good dry kindling.