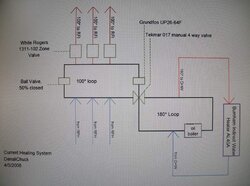

Attached is a diagram of my present system.

I'm planning to integrate a Tarm 40 that uses a flat plate hx to heat 1,200 gallons of unpressurized storage. I would like the house to receive heat from the Tarm first (when hot), the storage tank second and the oil boiler last. Since the radiant floor heat wants 100* water, I would like to be able to use the storage tank heat even if it is as low as 100*.

I also would like to begin heating a hot tub also using a flat plate hx and would like the heat to come from the Tarm first (when hot) and the storage tank second. I do not want to heat the tub with the oil boiler (or have somebody else mistakenly do this).

In the top of the storage tank I plan to run a home made copper tube hx to preheat DHW before running it into the current 40 gallon tank heater.

Where do I connect the new components to the existing system?

How do I control these different systems?

Thanks!

Chuck

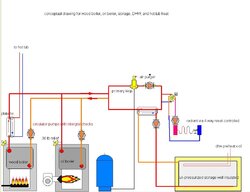

I'm planning to integrate a Tarm 40 that uses a flat plate hx to heat 1,200 gallons of unpressurized storage. I would like the house to receive heat from the Tarm first (when hot), the storage tank second and the oil boiler last. Since the radiant floor heat wants 100* water, I would like to be able to use the storage tank heat even if it is as low as 100*.

I also would like to begin heating a hot tub also using a flat plate hx and would like the heat to come from the Tarm first (when hot) and the storage tank second. I do not want to heat the tub with the oil boiler (or have somebody else mistakenly do this).

In the top of the storage tank I plan to run a home made copper tube hx to preheat DHW before running it into the current 40 gallon tank heater.

Where do I connect the new components to the existing system?

How do I control these different systems?

Thanks!

Chuck