i am having problems with my room air blower... after a few weeks or more of operation it starts making horrible noises... i am on my 4th blower and this one is doing the same thing. its at the point where you cannot hear the tv over the screetching. the screching comes and goes but the longer i use it the worse it gets. i have sent a blower back and was told no problem was found... my recent calls to englander i am told that this is possibly normal operation and a supervisor told me it is normal for squirl cage blowers to be noisy... i know the normal noise and every new blower has fixed it for weeks... this noise is not normal. there are also others on this site with the same issue as me.

i emailed video to her and am awaiting a phone call but i was told by people on this site that you are the guy to get in contact with.

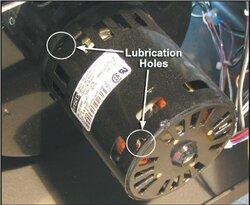

i took apart one of my old motors. i found the rear bearing is noisy and the ball bearings are actually blued. you can feel a major difference between the front and rear bearing. i think the rear bearing is getting hot because it sits in a rubber mount and there is no heatsink for it. the front bearing has the shaft that goes to the metal squirl cage. i think that keeps the front bearing cool. plus the motors fan is up front.

here are the viedos of my noise... any input is welcomed.

http://www.youtube.com/watch?v=rfSwRTaJ9FA

http://www.youtube.com/watch?v=tXNtirjbSAs

http://www.youtube.com/watch?v=tMT32LuQG1M

http://www.youtube.com/watch?v=EIgPsDi5CRA

http://www.youtube.com/watch?v=tNIUvEuZ9MY

i emailed video to her and am awaiting a phone call but i was told by people on this site that you are the guy to get in contact with.

i took apart one of my old motors. i found the rear bearing is noisy and the ball bearings are actually blued. you can feel a major difference between the front and rear bearing. i think the rear bearing is getting hot because it sits in a rubber mount and there is no heatsink for it. the front bearing has the shaft that goes to the metal squirl cage. i think that keeps the front bearing cool. plus the motors fan is up front.

here are the viedos of my noise... any input is welcomed.

http://www.youtube.com/watch?v=rfSwRTaJ9FA

http://www.youtube.com/watch?v=tXNtirjbSAs

http://www.youtube.com/watch?v=tMT32LuQG1M

http://www.youtube.com/watch?v=EIgPsDi5CRA

http://www.youtube.com/watch?v=tNIUvEuZ9MY