as i get closer to plumbing my radiant and tieing my wood boiler to my current heating system (baseboard w/oil boiler) i have some design questions. i currently have baseboard heat but the addition will be radiant. i am hoping to use 7/8" pex 16" oc but worried that the water temp would be too hot to run the same temp to the baseboard and radiant. what are my options to run two differant temps and do i need too? i have also been told to not exceed 80 deg floor temp with my hardwood floors.....

BASEBOARD AND RADIANT PLUMBING...... PRELIMINARY DRAWINGS

- Thread starter 91LMS

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

Clarkbug

Minister of Fire

You definitely want different temps for radiant as opposed to your baseboard heat.

Install a mixing valve that tempers the supply water temp headed out to the radiant loop. There are a few ways to set this up, and others with radiant systems can be of more help. But you for sure dont want to run the same temps through your baseboard and your in-floor loops.

Install a mixing valve that tempers the supply water temp headed out to the radiant loop. There are a few ways to set this up, and others with radiant systems can be of more help. But you for sure dont want to run the same temps through your baseboard and your in-floor loops.

Clarkbug

Minister of Fire

Not necessarily.

You can rig it up so that you use the return water from your baseboard that has dumped its high grade heat already and use that as your "hot" water for the radiant system. The other alternative is that if you have a storage system you can pull from the middle or bottom of the tank to use cooler water.

You can rig it up so that you use the return water from your baseboard that has dumped its high grade heat already and use that as your "hot" water for the radiant system. The other alternative is that if you have a storage system you can pull from the middle or bottom of the tank to use cooler water.

no storage right now. that would be the way to go if i pulled off the baseboard return. is there any trouble with too many feet of pipe in a loop like that? with this being the case my wood boiler would be tied in parralel to the oil boiler right? disconnect the return from the baseboard, pipe that to the input of my radiant manifold and the return from radiant back to the return on the oil boiler?

Clarkbug

Minister of Fire

Not necessarily.

It really depends on the layout of your current system, so a schematic diagram would really be quite useful. Depending on how you control your zoning currently and what you would like to do, there may be more (or less) to it than that.

Any chance you have a drawing of your layout handy?

It really depends on the layout of your current system, so a schematic diagram would really be quite useful. Depending on how you control your zoning currently and what you would like to do, there may be more (or less) to it than that.

Any chance you have a drawing of your layout handy?

i dont have a drawing but could in fact make one to give a better idea. basically tapping into the existing sytem of the house, the addition is 300% larger and planning on radiant. there are only two zones on the oil boiler right now. upstairs and the basement(which never gets used and was planning on using the baseboard for my over temp zone for my wood boiler). both of those zones have circulators on them so there are no zone valves. from there i have to plumb in my wood boiler and figure how to lower the water temp for my radiant. the oil boiler and the wood boiler are about 40 feet away from each other. was thinking i needed to circulate my wood boiler through the oil boiler to keep my domestic coil hot which is in the oil boiler. no boiler mate or storage planned at this point due to budget. i need heat and i need it fast, lol.

not sure the baseboard return water will work though as i would not have any water available for my radiant if the baseboard zone was not calling for heat at the same time. sounds like a mixing valve would work but what do you plumb up for the cold side of the valve, t'd into the return water from the radiant? where would the water go? variable speed circulator would be my only viable option???

If you took the water returning from your baseboard and sent it back out to the radiant lines it would work. Might not be optimal but simple and it would get you heated soon and cheap.

Even better would be to figure out how you would put a mixing valve between the baseboard return and radiant manifold supply and pipe it all with ball valve shutoffs and unions of some sort so that if it doesn't turn out to work as well as needed without mixing (or you just want to 'improve' it as funds and time become available) you could add in a mixing device.

The mixing device could be a simple manual or thermostatic 3-way valve or a motorized microprocessor/outdoor reset type setup that could control both baseboard and radiant systems to your requirements. Piping it so you could just "plug in" the mixing system without draining everything out and going through all that air chasing routine would be very valuable to you then.

But it might work just fine with the baseboard and radiant in series. I think especially if the radiant is under the subfloor or in a slab. The experts say you don't want the floor above low 80s but that might take 140F water to do when it's really cold out.

Even better would be to figure out how you would put a mixing valve between the baseboard return and radiant manifold supply and pipe it all with ball valve shutoffs and unions of some sort so that if it doesn't turn out to work as well as needed without mixing (or you just want to 'improve' it as funds and time become available) you could add in a mixing device.

The mixing device could be a simple manual or thermostatic 3-way valve or a motorized microprocessor/outdoor reset type setup that could control both baseboard and radiant systems to your requirements. Piping it so you could just "plug in" the mixing system without draining everything out and going through all that air chasing routine would be very valuable to you then.

But it might work just fine with the baseboard and radiant in series. I think especially if the radiant is under the subfloor or in a slab. The experts say you don't want the floor above low 80s but that might take 140F water to do when it's really cold out.

Hunderliggur

Minister of Fire

Pipe the HOT towards the radiant floor, add a mixing valve with the floor return as the "cold" side and the HOT to make 130F (or whatever) for the radiant. You are not wasting any heat. If HOT is 180 and radiant floor return is say 120, you will use 1/5 HOT and 4/5 return water (to give a 10F rise). Get the picture?

Hunderliggur said:Pipe the HOT towards the radiant floor, add a mixing valve with the floor return as the "cold" side and the HOT to make 130F (or whatever) for the radiant. You are not wasting any heat. If HOT is 180 and radiant floor return is say 120, you will use 1/5 HOT and 4/5 return water (to give a 10F rise). Get the picture?

i like that approach and seems it would be much easier for me to plumb where my radiant manifolds and wood boiler are so far from my existing plumbing. using the return side of the baseboard is a great idea however if my baseboard zone is not circulating there would be no water to supply my radiant with. just a headsup that the baseboard zone is heating 450 sq. ft of house that often gets heat from the wife cooking and such and this radiant is going to be heating about 1200 sq. ft.. i have a feeling that my radiant will call for more circulation that the baseboard.

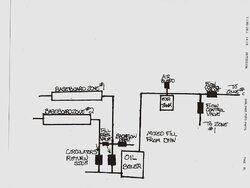

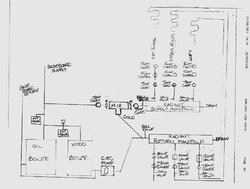

ok so i made a drawing of my existing heating system and another drawing of what i have drafted to plumb radiant heat in my addition and add my wood boiler. couple of issues i have come across from reading a multiple posts as i try to design my system. one of the issues is i am going to have to step my hot water supply down to my radiant as apposed to the supply on my existing baseboard. i also wonder if there is any need to temper the return water to the boiler. the biggest posed for me to determine wheter to hook the wood boiler in series or in paralled, keeping in my that i would like to use the domestic coil that is still in my OIL boiler to heat my dhw. okay boys tear it apart, tell me the issues or if i am actually on the right track..... thanks!

Attachments

Clarkbug

Minister of Fire

Well, I do see a few things....

If you are wanting to make sure that you always keep the oil hot for DHW, you will need a path that allows water to flow through the oil boiler after the wood boiler. The way your second pic is drawn right now, I dont see how that will happen.

To keep the oil boiler hot all the time, you would need to hook in series, not parallel, but you will have some standby losses that way.

Others can sort out the finer points better than I can, since Im still figuring those out myself. But it looks like you are getting there!

If you are wanting to make sure that you always keep the oil hot for DHW, you will need a path that allows water to flow through the oil boiler after the wood boiler. The way your second pic is drawn right now, I dont see how that will happen.

To keep the oil boiler hot all the time, you would need to hook in series, not parallel, but you will have some standby losses that way.

Others can sort out the finer points better than I can, since Im still figuring those out myself. But it looks like you are getting there!

i am guessing then that my best bet is to coil with a boilermate for my dhw at a later time and just rely on my oil for dhw this winter. once i am up and running and it all pans out i have hopes to fine tune its operation. hoping more posters will chime in on this and help out.

ewdudley

Minister of Fire

91LMS said:i am guessing then that my best bet is to coil with a boilermate for my dhw at a later time and just rely on my oil for dhw this winter. once i am up and running and it all pans out i have hopes to fine tune its operation. hoping more posters will chime in on this and help out.

Check out the mattd860 'figure eight' setup for connecting to existing fossil fuel system:

https://www.hearth.com/econtent/index.php/forums/viewthread/81444/P30/

The existing system stays pretty much untouched and the wood boiler circulates hot water 'backwards' through the existing boiler, unless there is load and then some or all of the wood boiler output goes the other way.

ewdudley

Minister of Fire

91LMS said:but with circulating water backwards wouldnt that affect the way that the baseboard water is circulated? or would i just be better off cost wise to buy the dhw coil for my boiler?

The 'backwards' flow just keeps the existing boiler hot when the wood boiler has nothing better to do. When the system tries to pull heat from the oil boiler like it always used to, the flow from the wood boiler is there to meet the need.

As far as DHW goes, if your existing boiler won't lose a lot of heat being kept hot then you're fine, else need to go ahead and get a boilermate or some such sooner or later.

so how do i go about having the wood boiler circulate backwards through the oil boiler? and does this happen all the time when there is not heat demand? once the plumbing part makes sense i am in a world of hurt trying to wire all this, lol. am i going to send my electricity bill through the ceiling running that circulator all the time? one of the baseboard zones in my existing system is in the basement and never used so i will be using that as my overtemp dump zone.

ewdudley

Minister of Fire

As with the mattd860 figure eight configuration, you have a circ that pumps hot water from the hot side of the wood boiler to the hot side of the fossil fuel boiler and it pulls from the cool side of the fossil boiler into the cool side of the wood boiler.91LMS said:so how do i go about having the wood boiler circulate backwards through the oil boiler?

Your existing loads will pull from the hot side of the fossil fuel boiler, same as they are plumbed and controlled now. Any new loads pull in parallel with the existing loads from the hot side of the fossil fuel boiler.

If the load flow is less than the boiler-to-boiler flow then some boiler-to-boiler flow goes to load and some recirculates backwards through the fossil fuel boiler.

If your load flow is more than the boiler-to-boiler flow then all the boiler-to-boiler flow will go to the loads and some load flow will recirculate through the fossil fuel boiler.

If there is no load flow than all the boiler-to-boiler flow will flow backwards through the fossil fuel boiler and your DHW stays hot.

Simplest would be all the time when the wood boiler is running, pretty much seventy watts all the time during heating season, pretty affordable probably.and does this happen all the time when there is not heat demand?

The other simplest would be to run the boiler-to-boiler circ only when any load circ is running, but this would not guarantee the the fossil fuel boiler stays hot and therefore DHW supply could suffer.

Better would be to run boiler-to-boiler circ whenever any load circ is running OR whenever aquastat on cool side of fossil fuel boiler is less than 150 degF (or whatever).

Good news! Making sense of the plumbing is the hard part.once the plumbing part makes sense i am in a world of hurt trying to wire all this, lol.

thanks ewdudley. i like the approach of using the aqua stat to circulate with no loads calling and below 150deg. i have no idea yet how this boiler will operate but possibly if i circulate all the time when the wood boiler is running it would prevent idling and creosote problems. the previous owner said he had not issues but i think he ran it flat out and its not a gasser.

- Status

- Not open for further replies.

Similar threads

- Replies

- 20

- Views

- 858

- Replies

- 8

- Views

- 852

- Replies

- 24

- Views

- 1K

- Replies

- 13

- Views

- 2K