This is a big read, but hopefully you guys will slog through it until the pictures show up :lol:

As we’ve slowly been trying to improve the energy loss out of this house, one of the things we’ve had to tackle is the 300 square feet of glass on the end of our Great Room. The lower 3 panels are actually a sliding door and glazed with low-end double-pane glass without any coatings for an assembly value of about R2. Sadly, the upper two windows are single pane uncoated glass for an assembly of about R1! Our first winter here, once outside temps dropped into the 50s, the Great Room became basically unusable because it was so cold. There’s two reasons for this. First, the room as running 1-2 degrees colder than the rest of the house due to heat loss out the glass. More important is something called mean radiant temperature. MRT has a HUGE impact on how comfortable you are!

So you guys probably learned in high school that heat moves in 3 ways: Conduction (stuff touching each other), Convection (thing heats up air, air moves to other object, warms other object up), and Radiation (stuff emits infrared photons). Radiation is the thing that doesn’t get enough attention. Your body can’t sense temperature. What it senses is how rapidly heat energy is moving in our out of your skin. When heat is moving into you, you perceive higher temperatures. When heat is moving out of you, you perceive lower temperatures. How fast the heat is moving is how you actually judge what temperature you think something is. This is why a book at 70F will feel warmer than a block of metal at 70F: They’re both colder than you, so you perceive heat flow out of you and into them but the heat moves MUCH faster into the metal, so you mistakenly perceive it as colder. While that example uses conduction, it sets us up to talk about mean radiant temperature. You emit infrared photons at whatever temperature your skin happens to be. These exiting photons represent a loss of heat. However, everything in your environment is also emitting infrared photons and some those hit you and you absorb them (which represents heat moving into you). When the stuff around you is about the same temperature as you, the photons you emit are balanced but the photons you absorb, so you don’t lose or gain any heat this way. The Mean Radiant Temperature is a measure of what temperature your surroundings feel like to you in terms of radiant energy. When the things around you are colder than you, the MRT is low and you lose significant heat energy by radiating it off towards your environment without getting an equal amount back from them.

There’s some practical implications to this. First, this is how those space/survival blankets work: shiny metal surfaces reflect infrared photons, rather than absorbing them, so your environment turns out to be reflections of you. So you get most of your emitted photons back because they bounce off the blanket and smack back into you. This is also why you can hang one of these blankets behind you while you sit in front of a fire and the infrared photons will come out of the fire, bounce off the blanket, and run into you, warming you. It’s like having a fire on multiple sides of you. Second, if you have a lot of uncoated glass that just transmits IR photons beside you in a room, that whole glazed area feels like it’s the same temperature as outside. So sitting in our Great Room, one whole end of the house felt like it was 50F outside, or -20F, depending on the day. Very uncomfortable.

Step one in fixing this room was to take the glass we could get to easily and make opaque insulating shutters for it. Basically, we leave the glass uncovered in the day so the sun comes in and then put the shutters in the windows (from the inside) at sunset. The shutters are made from sheets of Owens Corning Super TUFF-R. This is a polyisocyanurate insulation board with a reflective metal foil on one side. Dow Thermax would be better if you can get it because it’s safer. The important thing about this product is that it’s light, rigid, and has thermal properties we like. They’re easy to handle even though each shutter is almost 4x8 feet. If you drop one or one falls over, nothing gets hurt. They also move that part of the wall from R2 to R10, which is a BIG savings in energy! More importantly, we place them with the shiny metal side facing in to the room. What this means is that the shutters reflect the IR photons from the rest of the house, and us, back into the room, raising the MRT massively. Instead of feeling like the entire end of the room is at whatever the outside temperature is, it feels like it’s about 70F, since that’s what’s being reflected back. Suddenly, the room was comfortable, even in winter. Interior skin temperature improved dramatically. With the bare glass, the inside skin of the glass was about 40F when the outside temp was 20F. With the shutters in place, the interior skin of the shutter is at about 67-68F when the outside temp is 20F.

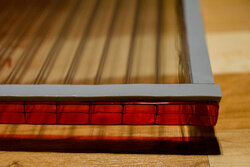

Step two in fixing the room was to do something about the single-pane glass windows up near the ceiling. The problem is that they’re 18 feet off the ground so we can’t put shutters in them and take them back out each day. However, at 150 square feet, we can’t really just ignore them either. We needed something we could put up there and just leave through the whole winter. For this, we decided to use the corrugated polycarbonate panels often used to build small greenhouses. The specific product we went with is Lexan Thermoclear triple-wall 19mm thick panels. The panels are a little better than R3.5, so combining that with the existing single-pane glass plus the air-gap between them ought to produce around an R5.5 assembly. In other words these should stop 80% of the heat that was previously falling out the crappy windows. Our plan was to make panels what would just fit within the jamb of the window and press forwards against the wood frame of the glazing in order to provide an air seal. The picture below shows most of the relevant details. The Thermoclear is divided up into cells with two cells being between the inside and outside world. We used polyethlyne tape to seal the ends of the cells and then normal weatherstripping to provide an air seal against the frame of the glazing.

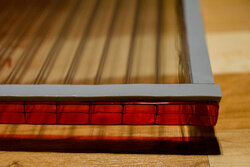

Same stuff, just a little more context:

This is an inside view. You can see how they do distort the outside world enough you can’t really use it as a picture window anymore, but that’s a decent tradoff for what we’re getting. They still let light and solar heat into the house all day but slow the rate of heat loss at night. You can see we secured the shutter by pressing it into the window using cleats I made from PVC that are screwed into the window jamb. The vertical stripe about 2/3rds of the way to the left is the seam we made because we had to join two panels due to the width of our windows.

From outside, you can see that stuff near the shutters is somewhat visible, but you can’t make out any of the outside loft just a few feet into the room.

There’s one final benefit: these are impact rated and effectively air and water proof. So if the glass is every broken (say during a hailstorm), I can unscrew these from the inside, screw them to the outside, run a bead of caulk around the edges, and I’ll be able to wait out however long it takes to order custom windows in this stupid size without having water leaks, air leaks, having to use tarps, etc.

As we’ve slowly been trying to improve the energy loss out of this house, one of the things we’ve had to tackle is the 300 square feet of glass on the end of our Great Room. The lower 3 panels are actually a sliding door and glazed with low-end double-pane glass without any coatings for an assembly value of about R2. Sadly, the upper two windows are single pane uncoated glass for an assembly of about R1! Our first winter here, once outside temps dropped into the 50s, the Great Room became basically unusable because it was so cold. There’s two reasons for this. First, the room as running 1-2 degrees colder than the rest of the house due to heat loss out the glass. More important is something called mean radiant temperature. MRT has a HUGE impact on how comfortable you are!

So you guys probably learned in high school that heat moves in 3 ways: Conduction (stuff touching each other), Convection (thing heats up air, air moves to other object, warms other object up), and Radiation (stuff emits infrared photons). Radiation is the thing that doesn’t get enough attention. Your body can’t sense temperature. What it senses is how rapidly heat energy is moving in our out of your skin. When heat is moving into you, you perceive higher temperatures. When heat is moving out of you, you perceive lower temperatures. How fast the heat is moving is how you actually judge what temperature you think something is. This is why a book at 70F will feel warmer than a block of metal at 70F: They’re both colder than you, so you perceive heat flow out of you and into them but the heat moves MUCH faster into the metal, so you mistakenly perceive it as colder. While that example uses conduction, it sets us up to talk about mean radiant temperature. You emit infrared photons at whatever temperature your skin happens to be. These exiting photons represent a loss of heat. However, everything in your environment is also emitting infrared photons and some those hit you and you absorb them (which represents heat moving into you). When the stuff around you is about the same temperature as you, the photons you emit are balanced but the photons you absorb, so you don’t lose or gain any heat this way. The Mean Radiant Temperature is a measure of what temperature your surroundings feel like to you in terms of radiant energy. When the things around you are colder than you, the MRT is low and you lose significant heat energy by radiating it off towards your environment without getting an equal amount back from them.

There’s some practical implications to this. First, this is how those space/survival blankets work: shiny metal surfaces reflect infrared photons, rather than absorbing them, so your environment turns out to be reflections of you. So you get most of your emitted photons back because they bounce off the blanket and smack back into you. This is also why you can hang one of these blankets behind you while you sit in front of a fire and the infrared photons will come out of the fire, bounce off the blanket, and run into you, warming you. It’s like having a fire on multiple sides of you. Second, if you have a lot of uncoated glass that just transmits IR photons beside you in a room, that whole glazed area feels like it’s the same temperature as outside. So sitting in our Great Room, one whole end of the house felt like it was 50F outside, or -20F, depending on the day. Very uncomfortable.

Step one in fixing this room was to take the glass we could get to easily and make opaque insulating shutters for it. Basically, we leave the glass uncovered in the day so the sun comes in and then put the shutters in the windows (from the inside) at sunset. The shutters are made from sheets of Owens Corning Super TUFF-R. This is a polyisocyanurate insulation board with a reflective metal foil on one side. Dow Thermax would be better if you can get it because it’s safer. The important thing about this product is that it’s light, rigid, and has thermal properties we like. They’re easy to handle even though each shutter is almost 4x8 feet. If you drop one or one falls over, nothing gets hurt. They also move that part of the wall from R2 to R10, which is a BIG savings in energy! More importantly, we place them with the shiny metal side facing in to the room. What this means is that the shutters reflect the IR photons from the rest of the house, and us, back into the room, raising the MRT massively. Instead of feeling like the entire end of the room is at whatever the outside temperature is, it feels like it’s about 70F, since that’s what’s being reflected back. Suddenly, the room was comfortable, even in winter. Interior skin temperature improved dramatically. With the bare glass, the inside skin of the glass was about 40F when the outside temp was 20F. With the shutters in place, the interior skin of the shutter is at about 67-68F when the outside temp is 20F.

Step two in fixing the room was to do something about the single-pane glass windows up near the ceiling. The problem is that they’re 18 feet off the ground so we can’t put shutters in them and take them back out each day. However, at 150 square feet, we can’t really just ignore them either. We needed something we could put up there and just leave through the whole winter. For this, we decided to use the corrugated polycarbonate panels often used to build small greenhouses. The specific product we went with is Lexan Thermoclear triple-wall 19mm thick panels. The panels are a little better than R3.5, so combining that with the existing single-pane glass plus the air-gap between them ought to produce around an R5.5 assembly. In other words these should stop 80% of the heat that was previously falling out the crappy windows. Our plan was to make panels what would just fit within the jamb of the window and press forwards against the wood frame of the glazing in order to provide an air seal. The picture below shows most of the relevant details. The Thermoclear is divided up into cells with two cells being between the inside and outside world. We used polyethlyne tape to seal the ends of the cells and then normal weatherstripping to provide an air seal against the frame of the glazing.

Same stuff, just a little more context:

This is an inside view. You can see how they do distort the outside world enough you can’t really use it as a picture window anymore, but that’s a decent tradoff for what we’re getting. They still let light and solar heat into the house all day but slow the rate of heat loss at night. You can see we secured the shutter by pressing it into the window using cleats I made from PVC that are screwed into the window jamb. The vertical stripe about 2/3rds of the way to the left is the seam we made because we had to join two panels due to the width of our windows.

From outside, you can see that stuff near the shutters is somewhat visible, but you can’t make out any of the outside loft just a few feet into the room.

There’s one final benefit: these are impact rated and effectively air and water proof. So if the glass is every broken (say during a hailstorm), I can unscrew these from the inside, screw them to the outside, run a bead of caulk around the edges, and I’ll be able to wait out however long it takes to order custom windows in this stupid size without having water leaks, air leaks, having to use tarps, etc.