So part of doing it your self is messing up. At least that's what I've been telling my self, it how you learn right?

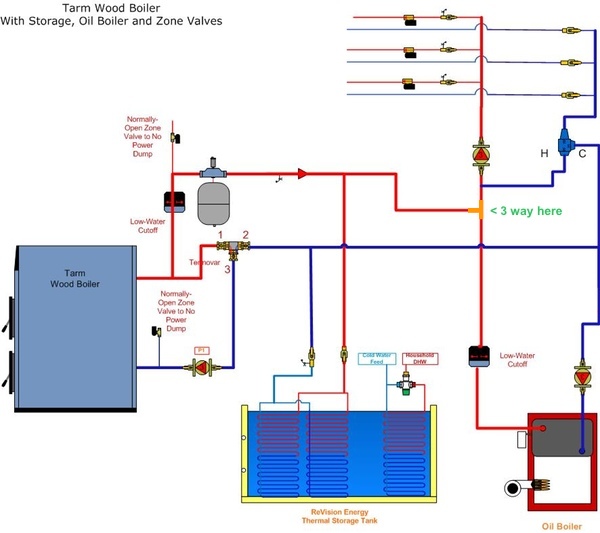

When I plumbed in my Tarm Solo Innova I thought I had done everything, well it turns out I had forgot to put a zone valve in the line to my oil boiler that is suppose to prevent hot water from circulating back into it when I'm on wood/storage. I solved this by just shutting a ball valve by hand and manually turning off my oil boiler. It worked for the winter but there was no automatic backup which is a bit of a pain.

So I have a choice a the moment. The way the folks at Revision Heat like to setup their systems is both the wood and fossil fuel boilers dump heat into storage. Currently I have a Johnson Controls A419 on my storage that I can use to control the oil boiler. If the tank dips below a set temp the oil boiler kicks on and bring it back up.

The way my system is setup now is my Taco Zone Controller is what controls the operation of my oil boiler via the end switch. If there's a all for heat the switch closes and allows the boiler to fire if it's below temp. Pretty simple.

So here's my question. I could go to the Revision model which is supposedly more efficient since you are running the oil boiler for longer period vs. short on/off cycles. They also assume I have a DHW coil in the tank, which I don't have at the moment, I have an indirect hot water heater.

The other option would be to use a 3 way valve in place of the other ZV and install it where everything Tees in. When the temp of the tank it down the oil boiler would work the way it's setup now and just kicking on when the zone controller calls for heat. When the tank is up to temp the oil boiler would be shot off and water would flow from the wood boiler/storage. I would be more or less using the A419 as a switch between the end switch and the oil boiler (which is how I have it wired at the moment). Pretty much when oil boiler is needed the wood/storage side shut off.

I plan on burning wood during the heating season and oil when there's no call for heat, pretty much just for hot water. Am I really going to gain that much by keeping my 820 gallon tank hot all summer just to supply my DHW (via indirect hot water heater) or am I better of just letting my oil boiler take care of it on an as need basis?

Here's what my setup looks like (thanks to Revision Heat):

Thanks,

K

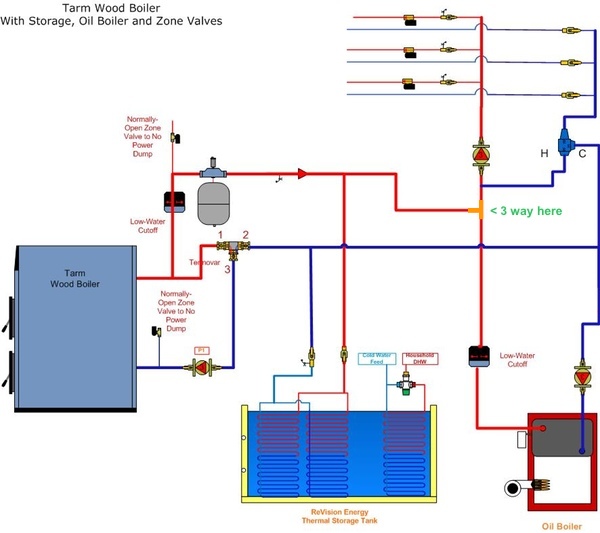

When I plumbed in my Tarm Solo Innova I thought I had done everything, well it turns out I had forgot to put a zone valve in the line to my oil boiler that is suppose to prevent hot water from circulating back into it when I'm on wood/storage. I solved this by just shutting a ball valve by hand and manually turning off my oil boiler. It worked for the winter but there was no automatic backup which is a bit of a pain.

So I have a choice a the moment. The way the folks at Revision Heat like to setup their systems is both the wood and fossil fuel boilers dump heat into storage. Currently I have a Johnson Controls A419 on my storage that I can use to control the oil boiler. If the tank dips below a set temp the oil boiler kicks on and bring it back up.

The way my system is setup now is my Taco Zone Controller is what controls the operation of my oil boiler via the end switch. If there's a all for heat the switch closes and allows the boiler to fire if it's below temp. Pretty simple.

So here's my question. I could go to the Revision model which is supposedly more efficient since you are running the oil boiler for longer period vs. short on/off cycles. They also assume I have a DHW coil in the tank, which I don't have at the moment, I have an indirect hot water heater.

The other option would be to use a 3 way valve in place of the other ZV and install it where everything Tees in. When the temp of the tank it down the oil boiler would work the way it's setup now and just kicking on when the zone controller calls for heat. When the tank is up to temp the oil boiler would be shot off and water would flow from the wood boiler/storage. I would be more or less using the A419 as a switch between the end switch and the oil boiler (which is how I have it wired at the moment). Pretty much when oil boiler is needed the wood/storage side shut off.

I plan on burning wood during the heating season and oil when there's no call for heat, pretty much just for hot water. Am I really going to gain that much by keeping my 820 gallon tank hot all summer just to supply my DHW (via indirect hot water heater) or am I better of just letting my oil boiler take care of it on an as need basis?

Here's what my setup looks like (thanks to Revision Heat):

Thanks,

K