I heat my house with an older pre-epa add-on woodfurnace. The woodburner has it's own blower. I have noticed that when I run my ng furnace my ductwork is a lot cooler to the touch at the same temperature than my woodburner. Does this mean that I need a more powerful blower on the woodburner?

blower question

- Thread starter pistonslap

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

It would be good to know the cfm the woodburner is rated at and the cfm of the NG furnace blower. How many btu is the NG furnace? It could just be that the woodburner is running hotter. But it could also be that the blower motor on the woodburner is running slow. Has it been cleaned and lubricated regularly and lately? Is the woodstove blower direct drive or belt driven? If belt driven is the tension too loose or too tight? If direct-drive is it single speed or multi-speed. If multi-speed, is it on a low speed tap? So many questions, but not enough info.

The furnace is an older model with no tags or info anywhere. The blower is a 1 speed direct drive squirrel cage type. One of the reasons I wonder about the blower is that there is plenty of heat in my ducts but it doesn't seem like it is pushing enough of it to my first and second floors. I can't use my ng blower because of the way I have the WB tapped in to my ductwork. When I use the woodburner blower my ducts get filled with very hot air and when I turn on my ng blower I think the force of it blocks the heat from the woodburner getting into the ducts. It blows very hot air for about a minute, then begins to cool off. If you feel the hot supply coming from the WB, it is very hot. If you feel the ductwork above where the WB taps in it is cool. The way my ng furnace and ducts are set up, it is the only place I can tap in and get heat to the front of my house. All I can tell you about my ng blower is that is is a 5 speed and it is set medium high. The woodburner blower doesn't have nearly as much force.

What about maintenance? Has the WB motor been oiled recently? Hard to say whether adequately sized, but usually a mfg. is aware of this and sizes close to average condition. What size is the WB squirrel cage? Does the WB motor have a rating plate?

Can you run the NG fan for circulation while the WB is going?

Can you run the NG fan for circulation while the WB is going?

I oiled it before the season. No tags on motor, If I remember correctly, it's a 10 or 12 " squirrel cage. No, you can't run the ng blower with the WB because of the way I have tapped the WB in. I may have to try a different way of tapping in. but I'm really restricted because of the closeness of the ducts for the front of the house to the ng furnace. My estimation of the age of this furnace is probably early 1980's

Can you draw a diagram of the install an post it? Jus wondering if this is an airflow and not a blower issue.

stoveguy2esw

Minister of Fire

if it is airflow,you may possibly be able to install a simple angled piece of sheet metal at the upwind side of the duct from where the WS duct enters. we did this with my dads setup and it worked quite well. ideally as the air passes the entry duct you want the air coming out of the WS duct into the mainline to pull the air out of the WS duct and carry it , creating a little "bump" sometimes does the trick by creating a small pocket of vacuum over the Ws duct , however the angle would have to be set just right , too steep and the main blower would create an eddy that would force the air back down the WS duct. too shallow and the vacuum effect would not be ample enough to pull out the heat. you would want to do this only if it was easy to access because you would probably have to tinker with the angle to get it right , there is no "set angle" im aware of that works for all. so if it is complecated to get at it , i'd try a different solution.

laynes69

Minister of Fire

There are problems when most of the wood furnaces aren't installed properly. If the wood furnace goes into the gas furnaces plenum and there are no dampers, you will lose alot of heat. I know this because my dad installed ours 18 years ago, and everytime the wood furnace kicked on, the air would try to go into the furnace instead of the house. Also with the setup he had, it was a parellel installation and he would have to really burn the furnace hot to try to heat the home. There was no cold air return or returns at all, that were hooked into the wood furnace. When you push air, something needs to be there to assist it through the home. I talked to alot of people and decided since I was installing all new duct work in the home, I would re-install the woodfurnace. I installed mine in series this time, and this way I dont need a single damper or baffle to stop the air from going the wrong way. When the wood furnace gets hot, the limit control tells the LP furnace to kick on the blowers of the LP furnace only, and it heats ALL of the air going around the firebox. Also this way the returns in the whole house are used. So much more heat from a different installation. When the blower kick on with the wood/furnace running, its no different heat than gas. You would never tell the difference. This can also be done with dividing the LP furnace plenum in 2 with a piece of sheetmetal. The bottom of the plenum would take trunk into the woodfurnace and the woodfurnace would comeout and go into the top of the LP Plenum an into the main heat trunk of the house. Ill see If I can find some different diagrams. As far as I know in Canada the only Legal way to tie a woodfurnace into a gas furnace is to install it in series. It makes much more sense.

I believe it's an airflow and a blower problem, but after looking at my setup, more of an air flow problem. My scanner is broken and it's been a long time since I used paint, so I will draw and post my set up in the morning. I appreciate the help. I know that I have plenty of heat in the firebox, I'm just not getting it out to the house.

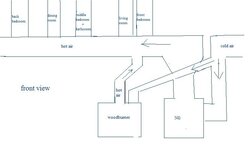

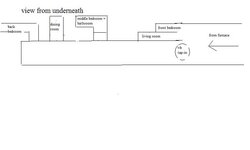

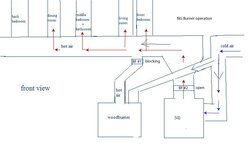

Here are some crude drawings of my set up. I installed an angled piece in the upwind side of the wb hot supply today. It seems to be letting the ng blower push the heat to the middle bedroom, dining room and back bedroom. It still is pushing it past the living room and front bedroom. The way those 2 ducts are set up is with the opening towards the ng furnace. I think they are to far forward of my hot air supply of my woodburner. As I said before, I am restricted by space to move the wb hot air supply back any further. Do you thiny adding a tee to the wb supply to go directly into those 2 ducts would solve the problem?

Attachments

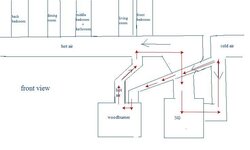

That's a big help PS. The pictures help visualize the system a lot better. First question going through my mind is - if the WB is running alone, what stops a circulation loop from skipping the main ducting? It looks like the problem is that there are no backflow dampers installed. I've added a picture to a possible circulation loop that may be occurring.

To test whether this is happening, remove the NG system air filter and tape a thin sheet of cardboard over it or heavy paper. The idea is to change the filter into a damper that blocks airflow. THIS IS A TEMPORARY TEST. Be sure to turn the NG furnace off while testing or you may destroy the furnace fan and have severe overheating. Reinsert the blocked filter and run on Woodburner ONLY. If the WB blower efficiency is dramatically improved, then this is the issue. REMOVE the filter and remove the paper covering. Restore all systems to normal operations.

If this is the case, take a look at the installation manual recommendations for installation for other wood burning furnaces. Also note the duct to combustible surface requirements. Best to work with a sheet metal shop or heating contractor to make safe modifications.

http://www.yukon-eagle.com/pdfs/jack.pdf page 7 for ducting

http://www.magnumheat.com/downloads/public/Magnum-6500-7500-Manual.pdf - page 19

If you are using round pipe from the WB furnace, here is an example of a round pipe, backdraft damper:

http://www.continentalfan.com/pdfs/bddampers.pdf

http://www.rewci.com/416splobada.html

To test whether this is happening, remove the NG system air filter and tape a thin sheet of cardboard over it or heavy paper. The idea is to change the filter into a damper that blocks airflow. THIS IS A TEMPORARY TEST. Be sure to turn the NG furnace off while testing or you may destroy the furnace fan and have severe overheating. Reinsert the blocked filter and run on Woodburner ONLY. If the WB blower efficiency is dramatically improved, then this is the issue. REMOVE the filter and remove the paper covering. Restore all systems to normal operations.

If this is the case, take a look at the installation manual recommendations for installation for other wood burning furnaces. Also note the duct to combustible surface requirements. Best to work with a sheet metal shop or heating contractor to make safe modifications.

http://www.yukon-eagle.com/pdfs/jack.pdf page 7 for ducting

http://www.magnumheat.com/downloads/public/Magnum-6500-7500-Manual.pdf - page 19

If you are using round pipe from the WB furnace, here is an example of a round pipe, backdraft damper:

http://www.continentalfan.com/pdfs/bddampers.pdf

http://www.rewci.com/416splobada.html

Attachments

I see what you mean. I will give that a try tomorrow morning. If this is the case, would the solution be a 100% damper between the wb and the ng?

Also, I really don't know much about hvac, but am I correct in thinking that the loop stops the cold air from circulating, therefore causing no airflow thru the entire system other than what gets pushed down thru the stairwells?

The loop becomes self contained. Air will take the path of least resistance. If it is easier to circulate in a loop, then circulate the air through the house and back through the returns, then it will.

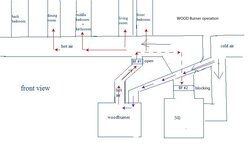

I added some links to the prior post for you that illustrate proper installation with a backdraft damper. Yukon has a good couple examples. Notice that they set up backflow prevention for when the NG is running as well as one for when the WB is running. It's also possible that the NG furnace's efficiency is also being compromised by a loop through the wood furnace when the NG is running. I strongly recommend having a heating professional evaluate the situation. Get a few quotes for the ductwork modifications and backdraft damper additions. I suspect you will end up saving wood and NG with the system running right.

I added some links to the prior post for you that illustrate proper installation with a backdraft damper. Yukon has a good couple examples. Notice that they set up backflow prevention for when the NG is running as well as one for when the WB is running. It's also possible that the NG furnace's efficiency is also being compromised by a loop through the wood furnace when the NG is running. I strongly recommend having a heating professional evaluate the situation. Get a few quotes for the ductwork modifications and backdraft damper additions. I suspect you will end up saving wood and NG with the system running right.

Attachments

When I installed the ductwork on the woodburner, I put manual 100% dampers on the hot and cold air returns on the woodburner. But I can see that you would want to put a different type that would open and close by itself when the ng furnace runs. I will talk to my furnace guy about that,

Try the ** temporarily ** blocked NG system filter test with the woodburner running. If it makes a big difference, you're on the right track.

I blocked the filter opening. I did notice a slight rise in the airflow. When I opened the ng furnace cover, there was definitly warm air backing up into the area where the filter was. So I think a damper is in order. Also I need to seal some airleaks in my ductwork. I think every little bit will help. I'll keep you posted.

laynes69

Minister of Fire

Down the road install in series and you wont have a problem with heat output. Last night got down to 10 degrees. 2400 square foot home, 10 foot ceilings both up and down, 150+ year old home, house temp 76 degrees both up and down. You wont have to worry about any dampers with a series installation.

Is there a formula for figuring cfm? I found a tag on the underside of my blower motor. I cleaned it up and everything is still readable. It says 115v, 60hz, 3.6A and 1500 rpm. There is no horsepower on the tag. The squirrel cage dimensions are 10" round by 5" wide. Also, if the problem is cfm, would I raise the cfm by higher rpm or bigger squirrel cage?

It sounds like it maybe a 1/4 hp motor. A 10" x 5" wheel is pretty tiny. I'm guessing it's around 900-1000 cfm, but that's just a guess. Is this a direct or belt driven blower? If direct and there's room, a wider wheel would make a difference. For example, a 10 x 8 wheel with a 1/3hp, 4 speed motor will deliver about 900-1500 cfm. If belt driven, see if it has an adjustable drive pully. If so, that may be set to drive the blower faster.

It's a direct drive. I disconnected the duct coming out of the wb, and the amount of force coming out of it is about the same as you get out of your dashboard vents in a car with the air on high.

laynes69

Minister of Fire

Thats why I use my main furnace blower only to push the heat from the wood furnace. With my new ductwork, the main heat trunk is close to 45 feet long, it goes from the basement to the attic. Try taking 2 little blowers that came with my furnace and push heat upstairs with it, no way. When im burning with a good fire, the heat that comes out of all of my ducts feels like gas heat, and you feel the heat 4 feet in the air. Used to be you'd be lucky if you felt the wood heat a foot off the floor.

Gooserider

Mod Emeritus

pistonslap said:Is there a formula for figuring cfm? I found a tag on the underside of my blower motor. I cleaned it up and everything is still readable. It says 115v, 60hz, 3.6A and 1500 rpm. There is no horsepower on the tag. The squirrel cage dimensions are 10" round by 5" wide. Also, if the problem is cfm, would I raise the cfm by higher rpm or bigger squirrel cage?

Either

You can spin the same size cage faster or you can spin a bigger cage at the same speed, both will move more air. Note that a bigger cage would also need a matching enclosure. The faster you spin the cage, the noisier it will be. Either option may well require a bigger motor, as mfgr's for obvious reasons will tend to use the least amount of motor they can to get a job done.

You can spin the same size cage faster or you can spin a bigger cage at the same speed, both will move more air. Note that a bigger cage would also need a matching enclosure. The faster you spin the cage, the noisier it will be. Either option may well require a bigger motor, as mfgr's for obvious reasons will tend to use the least amount of motor they can to get a job done. If there is a brand on the blower, I would see if the mfgr has a website with specs on it, and see what alternatives they offer. I'm not sure offhand about squirrel cage blowers, but I know that you can get very good specs from the folks that make the square "muffin" fans that are used in PC's

Gooserider

- Status

- Not open for further replies.

Similar threads

- Replies

- 2

- Views

- 288

- Replies

- 1

- Views

- 607

- Replies

- 3

- Views

- 537

- Replies

- 17

- Views

- 793