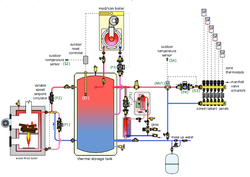

I think this concept, designed by John Siegenthaler www.hydronicpros.com covers most of the functions that many want.

The boiler is protected from low return temperature by a variable speed circ. I like this for high output boilers especially. Less cost and less pressure drop compared to large loading units, this could be an ECM pump for additional energy savings. Actually all the circs could be ECM which are mandated in Europe now for all heating pumps.

I believe with a swing check, and generously sized boiler piping, the boiler would thermo-siphon for over-heat protection, remove any spring checks from the pump! It seems to work well in the loading units with a swing ck.

The controls could be very simple. The wood boiler runs it's own pump P-1, all seem to have a relay output for that function. The load circ P-2 could be a brand with the logic built on, or run by an inexpensive solar differential control, just about all brands and models of solar controllers have variable speed functions built in nowadays.

The buffer tank serves as a hydraulic separator and a fairly good air removal point for the boiler. as well as a dirt separation function.

Boiler back up with a mod con has some buffer space for small micro zones. Loads could be removed from the tank with reset temperature controls MV-1.

DHW is via a 30 plate HX. I have proven this method on my own system for a year now. I've found the Harwil Q8-N flow switch works perfectly and triggers at 1/2 gpm flow. Protect the DHW temperature with a listed 3 way thermostatic valve.

DHW backup could be a small tankless gas or electric. if I were to buy a new mod con boiler I would use a brand with them DHW HX built in. So boiler back up and DHW from one unit. Really back up could be oil, gas, LP, electric, heat pump, any source you chose. Back up DHW could also be a small electric HW heater too.

There are trade offs on any system design, this simple to plumb option shows a one tank concept that covers most options that customers want, with Caleffi components of course

Thoughts, suggestions?

The boiler is protected from low return temperature by a variable speed circ. I like this for high output boilers especially. Less cost and less pressure drop compared to large loading units, this could be an ECM pump for additional energy savings. Actually all the circs could be ECM which are mandated in Europe now for all heating pumps.

I believe with a swing check, and generously sized boiler piping, the boiler would thermo-siphon for over-heat protection, remove any spring checks from the pump! It seems to work well in the loading units with a swing ck.

The controls could be very simple. The wood boiler runs it's own pump P-1, all seem to have a relay output for that function. The load circ P-2 could be a brand with the logic built on, or run by an inexpensive solar differential control, just about all brands and models of solar controllers have variable speed functions built in nowadays.

The buffer tank serves as a hydraulic separator and a fairly good air removal point for the boiler. as well as a dirt separation function.

Boiler back up with a mod con has some buffer space for small micro zones. Loads could be removed from the tank with reset temperature controls MV-1.

DHW is via a 30 plate HX. I have proven this method on my own system for a year now. I've found the Harwil Q8-N flow switch works perfectly and triggers at 1/2 gpm flow. Protect the DHW temperature with a listed 3 way thermostatic valve.

DHW backup could be a small tankless gas or electric. if I were to buy a new mod con boiler I would use a brand with them DHW HX built in. So boiler back up and DHW from one unit. Really back up could be oil, gas, LP, electric, heat pump, any source you chose. Back up DHW could also be a small electric HW heater too.

There are trade offs on any system design, this simple to plumb option shows a one tank concept that covers most options that customers want, with Caleffi components of course

Thoughts, suggestions?