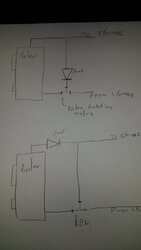

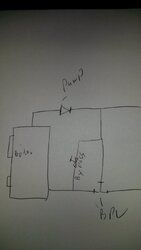

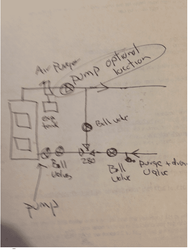

I am getting ready to hook up my storage tanks and need to fix some of my plumbing first. I screwed up the boiler pump location as seen in the top diagram. (it's currently works right now without storage because I took out the cartrage) So I need to move the pump to either like the second diagram or place the pump between the BPV and return on the boiler. It seems to me most times it's located near the return, but I would like to locate it on the top because it would be a much much easier plumbing job involving very little time and

effort. Is there any advantage or disadvantage to either?

effort. Is there any advantage or disadvantage to either?