I don't want to try to re-invent the wheel so can anyone with similar setups offer input?

My existing system is an oil boiler with indirect DHW, cast iron base board zones, and radiant zones. Tekmar controls are used to fire the boiler, run circulators and mix temperature for the radiant zones. I'm adding a BioMax 60 and hot water storage to the system.

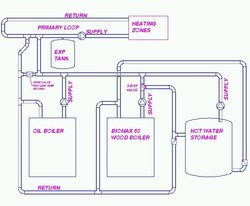

The following diagram shows my initial attempt at how I think this should look. A brief description would be as follows:

When wood boiler fires, wood pump is on. If no call for heat, 3-way directs to storage.

When there's a call for heat, if storage temp > primary loop temp then storage pump on.

If storage temp < primary loop, then 3-way directs to primary.

If boiler temp drops, then oil boiler fires for heat to primary loop.

Oil would only supply to primary, not to wood boiler or storage.

Does this logic sound correct? Does the piping layout allow this? Suggestions?

Thanks, Rob.

My existing system is an oil boiler with indirect DHW, cast iron base board zones, and radiant zones. Tekmar controls are used to fire the boiler, run circulators and mix temperature for the radiant zones. I'm adding a BioMax 60 and hot water storage to the system.

The following diagram shows my initial attempt at how I think this should look. A brief description would be as follows:

When wood boiler fires, wood pump is on. If no call for heat, 3-way directs to storage.

When there's a call for heat, if storage temp > primary loop temp then storage pump on.

If storage temp < primary loop, then 3-way directs to primary.

If boiler temp drops, then oil boiler fires for heat to primary loop.

Oil would only supply to primary, not to wood boiler or storage.

Does this logic sound correct? Does the piping layout allow this? Suggestions?

Thanks, Rob.