Hello Everyone,

I have been enjoying all the post and info from here. I have a HWB, Corn Boiler, and Electric Boiler all that I have built over the last 5 years. I am planning on building a shop next spring and will need to relocate and rework my entire system next summer. I am in the planning stages now. My house is 2500 sq' single story and the shop will be 1800 sq'.

I have a HW Coil in my propane furnace and a Heat Exchanger for DHW in my house. I will be adding a AHU, IFH, and DHW Heat Exchanger for shop. Also I want to put a Unit Heater in my crawl space as a place to dump heat in an emergency and to play with just to see how much heat it will take to warm up my floors. The UH will be in series with my storage tank.

I also plan on retiring the home built wood boiler and get a high efficiency one. (Still not sure what to buy). I start the old girl in the middle of Nov. and run it into April or until the wood runs out. I burn 10 pulp cords a year right now. The corn burner works well. It cannot keep up with the load of my house in the coldest part of winter. I have not used it in two years due to corn prices (Damn ethanol plants). First year corn was $70.00 a ton. I shut it off when it hit $150.00 a ton.

I want to run my secondary loop circulating pump off of a aquastat in the storage tank.

I am having a hard time wrapping my arms around the idea of starting a fire everyday with high efficiency boiler.

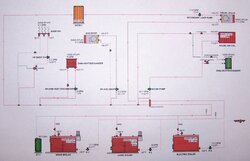

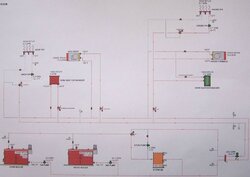

A picture is worth a thousand words so I will try to attach plan. All equipment possible will be in shop.

Drawing from TACO Software.

I am looking for comments

Thanks,

I have been enjoying all the post and info from here. I have a HWB, Corn Boiler, and Electric Boiler all that I have built over the last 5 years. I am planning on building a shop next spring and will need to relocate and rework my entire system next summer. I am in the planning stages now. My house is 2500 sq' single story and the shop will be 1800 sq'.

I have a HW Coil in my propane furnace and a Heat Exchanger for DHW in my house. I will be adding a AHU, IFH, and DHW Heat Exchanger for shop. Also I want to put a Unit Heater in my crawl space as a place to dump heat in an emergency and to play with just to see how much heat it will take to warm up my floors. The UH will be in series with my storage tank.

I also plan on retiring the home built wood boiler and get a high efficiency one. (Still not sure what to buy). I start the old girl in the middle of Nov. and run it into April or until the wood runs out. I burn 10 pulp cords a year right now. The corn burner works well. It cannot keep up with the load of my house in the coldest part of winter. I have not used it in two years due to corn prices (Damn ethanol plants). First year corn was $70.00 a ton. I shut it off when it hit $150.00 a ton.

I want to run my secondary loop circulating pump off of a aquastat in the storage tank.

I am having a hard time wrapping my arms around the idea of starting a fire everyday with high efficiency boiler.

A picture is worth a thousand words so I will try to attach plan. All equipment possible will be in shop.

Drawing from TACO Software.

I am looking for comments

Thanks,