I placed a deposit on a 1 year old econoburn 100 and I'll be picking it up in a couple weeks. I want to get the schematics down before the unit arrives so I'm ready for install.

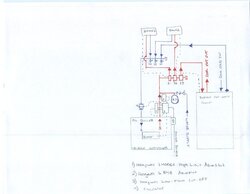

My current setup is an oil boiler feeding three zones. One being an indirect water heater. The house is 2600 s.f. heated by two hydro-air units making up the 2nd and 3rd zone, respectively. The existing boiler diagram can be seen with the attachment.

Power is supplied to the L8418 Aquastat which I assume acts as the primary controller. From there it controls the circulator pump on the return line and burner. What's suprising is there's no low voltage wiring from the zone valves to the aquastat so how would this trigger the boiler to turn on?

With the addition of the wood boiler, do I have to add a bypass connecting both the supply & return headers so the wood boiler primary pump doesn't create a dead-head situation? If needed, how would this affect the oil boiler's operation in the event the wood boiler is not in use. I intend on installing a set of valves to isolate both boilers for servicability and summer use.

Also, If I do have to install a bypass, would I have to rewire any of the controls so the oil boiler doesn't turn on when the wood boiler is in use. If the wood boiler primary loop is connected to the zone headers above the oil boiler, wouldn't there be stagnant, cold water in the oil boilers supply riser triggering the oil boiler to fire?

My current setup is an oil boiler feeding three zones. One being an indirect water heater. The house is 2600 s.f. heated by two hydro-air units making up the 2nd and 3rd zone, respectively. The existing boiler diagram can be seen with the attachment.

Power is supplied to the L8418 Aquastat which I assume acts as the primary controller. From there it controls the circulator pump on the return line and burner. What's suprising is there's no low voltage wiring from the zone valves to the aquastat so how would this trigger the boiler to turn on?

With the addition of the wood boiler, do I have to add a bypass connecting both the supply & return headers so the wood boiler primary pump doesn't create a dead-head situation? If needed, how would this affect the oil boiler's operation in the event the wood boiler is not in use. I intend on installing a set of valves to isolate both boilers for servicability and summer use.

Also, If I do have to install a bypass, would I have to rewire any of the controls so the oil boiler doesn't turn on when the wood boiler is in use. If the wood boiler primary loop is connected to the zone headers above the oil boiler, wouldn't there be stagnant, cold water in the oil boilers supply riser triggering the oil boiler to fire?

They're just the only ones I could find who had all the different temperature and open/close on rise combinations that I needed. Also, they're fairly cheap and made in the USA, which are two things I like!

They're just the only ones I could find who had all the different temperature and open/close on rise combinations that I needed. Also, they're fairly cheap and made in the USA, which are two things I like!