I'd like to build a small lean-to, approx. 16 ft in length down the side of my shed. I don't have much room to play with, so I'd like to support the joists of the lean-to on a header, which I will attach to the side of the shed (as opposed to putting posts next to the shed to support the header). I don't know too much about carpentry stuff, but am wondering if the header will be able to support the load of the joists/snow etc. if it is just screwed/nailed into the 2x4 framing of the shed. I can brush off the snow in the winter, so that can be factored in, but I was wondering if anyone could give me any advice about whether this is doable? Any specific way i should attach the header to the shed wall?

Building a lean-to off side of shed - need advice

- Thread starter MissMac

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Yes it should be able to support it. You should lag the header to the wall studs with structural lagsI'd like to build a small lean-to, approx. 16 ft in length down the side of my shed. I don't have much room to play with, so I'd like to support the joists of the lean-to on a header, which I will attach to the side of the shed (as opposed to putting posts next to the shed to support the header). I don't know too much about carpentry stuff, but am wondering if the header will be able to support the load of the joists/snow etc. if it is just screwed/nailed into the 2x4 framing of the shed. I can brush off the snow in the winter, so that can be factored in, but I was wondering if anyone could give me any advice about whether this is doable? Any specific way i should attach the header to the shed wall?

Okay thanks bholler - i was thinking of using some carriage bolts, but wasn't sure. What size of lags would you suggest, given that i'd be tapping into the 2" side of the 2x4s?Yes it should be able to support it. You should lag the header to the wall studs with structural lags

Carriage bolts would be fine but harder. I use ledger lock bolts for things like that. 3.5 or 4" should doOkay thanks bholler - i was thinking of using some carriage bolts, but wasn't sure. What size of lags would you suggest, given that i'd be tapping into the 2" side of the 2x4s?

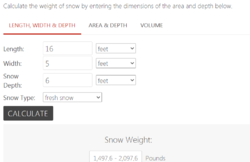

There are many factors involved with the construction. Rafter span, beam span, roof pitch, snow load in your area, wind speed, etc. Some will say to get a structural engineer involved, others will say the whole thing can be built with 2x4s. Below are a couple of screws that can be used in place of lag bolts to attach the ledger to the wall.

Amazon product ASIN B000LNVQYAor

Amazon product ASIN B000LNVQYAor

GRK Fasteners 5/16 in. x 3-1/8 in. Star Drive Washer Head Rugged Structural Wood Screw (45-Pack) 112221 - The Home Depot

GRK Fasteners RSS screw is made from Climatek coated and hardened steel. Its sharp threads and point bite instantly into material (including hardwood), reducing the splitting effect caused by smaller shanks. Its washer type head has no sharp edges like conventional lag screws and the added...

www.homedepot.com

Yup that's the type I useThere are many factors involved with the construction. Rafter span, beam span, roof pitch, snow load in your area, wind speed, etc. Some will say to get a structural engineer involved, others will say the whole thing can be built with 2x4s. Below are a couple of screws that can be used in place of lag bolts to attach the ledger to the wall.

Amazon product ASIN B000LNVQYAor

GRK Fasteners 5/16 in. x 3-1/8 in. Star Drive Washer Head Rugged Structural Wood Screw (45-Pack) 112221 - The Home Depot

GRK Fasteners RSS screw is made from Climatek coated and hardened steel. Its sharp threads and point bite instantly into material (including hardwood), reducing the splitting effect caused by smaller shanks. Its washer type head has no sharp edges like conventional lag screws and the added...www.homedepot.com

Sawset

Minister of Fire

I chose not to attach to the house. Attaching would mean attachment worries, and frost depth footings, and with the rocky boulder gravel just beneath the surface, that didn't sound appealing.

4x9x14ft

4 cords or so.

It's been 5yrs. Used concrete patio block for pads.

4x9x14ft

4 cords or so.

It's been 5yrs. Used concrete patio block for pads.

Attachments

it's going to be narrow (around 6 ft, and only about 5 ft off the ground at the high point - just enough for me to hide my quad in. if i put down concrete blocks and 4x4 or something to support the header where it bumps into the shed, i will lose precious head room which is already super tight (because of the slope of my shed roof). i'm just trying to scab something together cheap and easy to store the quad in, and the shed itself is not the nicest shed. the plan is someday to build a nice big garage - it's just not in the cards right now. thanks for the ideas with those special screws though - i'm definitely going to use those!

I don;t think I would have a semi roof 6 foot wide hanging off any of my walls with out tieing it into the structure every 2 - 3 foot.

Similar to this:

Or you could put in angled supports that come down against the structure lower then the roof say at a 30 - 45 degree angle.

Similar to this:

Similar to this:

Or you could put in angled supports that come down against the structure lower then the roof say at a 30 - 45 degree angle.

Similar to this:

It's no different than having a deck hanging on the house with a ledger board. It's all about the shear strength of the fasteners. Yes, placing the rafters on top of the wall will support much more weight because you now are dealing with the shear strength of the wood. It is all dependent on the snow load in the area and if the screws can be installed with the proper spacing required to handle the load.

peakbagger

Minister of Fire

One thing I cringe at on adding to a building is not factoring in possible side to side loading on the original structure. Ideally you want the end walls of the new shed to be diagonally braced. You can either use solid plywood or just an X brace corner from diagonal corners and tied together where they cross. This stiffens the structure from side loads. Where those side loads come from and how much they are is the complicated part. Ideally if the original shed has solid walls or X bracing the X bracing on the shed may not be needed.

I saw a wood shed once that was four poles on each corner buried about a foot deep and a shallow angled roof on top with open sides. We had a bunch of snow in a two week period and there was about 6 feet of snow on the roof. The structure actually stared twisting as though a big hand was trying to rotate the roof relative to the columns on all four corners. The columns started cracking lengthwise. Luckily the wood was stacked to the rafters so as it twisted the roof dropped and transferred the load to the stacked wood inside. A couple of bolted or screwed X braces on two sides and the back would have most likely stopped that. My woodshed is similar but with X braces. I still stack the wood real close to the bottom of the rafters in a "belt and suspenders" approach

Roofs rarely fail due to structural issues, its usually the details that are the devil. Almost every deck and shed roof collapse I have ever heard of is someone nailed the header to the house instead of through bolting or using structural screws. The structure gets overloaded, the header pulls out from the building and it collapses. BTW, the other issue I have heard of is crappy flashing where a pocket forms between the wall and shed roof or deck where water can collect. This rots the header or the wall studs or both until something fails. Even with an overhang, the siding must be removed and flashing installed up the wall under the siding and down the roof to redirect water down the shed roof or deck instead of this pocket.

Structural engineers pay a bundle for liability coverage as they frequently are dealing with modifications to existing structures. They have to go super conservative on any design they do as they own the liability for the life of the structure. Carpenters on the other hand usually wing it and work under a LLC so even if it fails they are long gone and have protected their assets.

I saw a wood shed once that was four poles on each corner buried about a foot deep and a shallow angled roof on top with open sides. We had a bunch of snow in a two week period and there was about 6 feet of snow on the roof. The structure actually stared twisting as though a big hand was trying to rotate the roof relative to the columns on all four corners. The columns started cracking lengthwise. Luckily the wood was stacked to the rafters so as it twisted the roof dropped and transferred the load to the stacked wood inside. A couple of bolted or screwed X braces on two sides and the back would have most likely stopped that. My woodshed is similar but with X braces. I still stack the wood real close to the bottom of the rafters in a "belt and suspenders" approach

Roofs rarely fail due to structural issues, its usually the details that are the devil. Almost every deck and shed roof collapse I have ever heard of is someone nailed the header to the house instead of through bolting or using structural screws. The structure gets overloaded, the header pulls out from the building and it collapses. BTW, the other issue I have heard of is crappy flashing where a pocket forms between the wall and shed roof or deck where water can collect. This rots the header or the wall studs or both until something fails. Even with an overhang, the siding must be removed and flashing installed up the wall under the siding and down the roof to redirect water down the shed roof or deck instead of this pocket.

Structural engineers pay a bundle for liability coverage as they frequently are dealing with modifications to existing structures. They have to go super conservative on any design they do as they own the liability for the life of the structure. Carpenters on the other hand usually wing it and work under a LLC so even if it fails they are long gone and have protected their assets.

Sawset

Minister of Fire

1500-2000lb for 6ft of snow on a 4x14 lean too. X-braces sound very reasonable under those conditions.One thing I cringe at on adding to a building is not factoring in possible side to side loading on the original structure. Ideally you want the end walls of the new shed to be diagonally braced. You can either use solid plywood or just an X brace corner from diagonal corners and tied together where they cross. This stiffens the structure from side loads. Where those side loads come from and how much they are is the complicated part. Ideally if the original shed has solid walls or X bracing the X bracing on the shed may not be needed.

I saw a wood shed once that was four poles on each corner buried about a foot deep and a shallow angled roof on top with open sides. We had a bunch of snow in a two week period and there was about 6 feet of snow on the roof. The structure actually stared twisting as though a big hand was trying to rotate the roof relative to the columns on all four corners. The columns started cracking lengthwise. Luckily the wood was stacked to the rafters so as it twisted the roof dropped and transferred the load to the stacked wood inside. A couple of bolted or screwed X braces on two sides and the back would have most likely stopped that. My woodshed is similar but with X braces. I still stack the wood real close to the bottom of the rafters in a "belt and suspenders" approach

Roofs rarely fail due to structural issues, its usually the details that are the devil. Almost every deck and shed roof collapse I have ever heard of is someone nailed the header to the house instead of through bolting or using structural screws. The structure gets overloaded, the header pulls out from the building and it collapses. BTW, the other issue I have heard of is crappy flashing where a pocket forms between the wall and shed roof or deck where water can collect. This rots the header or the wall studs or both until something fails. Even with an overhang, the siding must be removed and flashing installed up the wall under the siding and down the roof to redirect water down the shed roof or deck instead of this pocket.

Structural engineers pay a bundle for liability coverage as they frequently are dealing with modifications to existing structures. They have to go super conservative on any design they do as they own the liability for the life of the structure. Carpenters on the other hand usually wing it and work under a LLC so even if it fails they are long gone and have protected their assets.

We get a foot or so blown on, even after extreme blizzarding. Other parts of the house roofing gets more, so something to keep in mind. I have a snow shovel (snow puller) on a long handle for dragging off the excessive snow in the valleys.

peakbagger

Minister of Fire

My town in NH is up there on snow load, 95 pound per square foot (compared to 40 in southern NH). The town next to me can be as high as 110 PSF (there is an elevation adjustment, the higher the house the more snow load). We are in a "funnel" just north or Mt Washington so fronts coming from the west hit the mountains and dump snow, on occasion the snow goes north and hits our towns on occasion. The only other towns with higher loads are mostly town where there are no residential buildings.

Similar threads

- Replies

- 0

- Views

- 471

- Replies

- 0

- Views

- 340