loadstarken

Burning Hunk

Find one on craigslist and I'm sure we could find a board member in the area pick it up and send it to you.

Yeah, I don't get into 50"+ Oak every day. Lot's of 18-24" trunks.

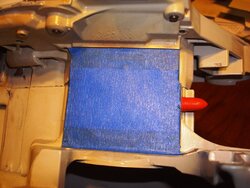

Hey MasterMech,View attachment 91643 View attachment 91645View attachment 91642

View attachment 91647 View attachment 91646

This is the flywheel side press tool. This one is well worth buying if you do this kind of work. The plates are numbered/drilled for multiple saws and make pressing the crank out of the case half a snap. Also works for pulling the crank/bearing assembly back into the case.

Gonna sell a 460 to get a "1" series saw?

Why? When you have so many others that are Not?

That 460 will run circles around your 034. Makes the 230C seem like a child, the 034 is a juvenile, while the 460 is a Grown man the dont take Chit from anyone

What ya askin???

I fully know what to expect from this MS460 when it's complete. It's going to run an 8 pin rim and 20" Bar for awhile once it's complete until I sell it. (date to be determined,

I fully know what to expect from this MS460 when it's complete. It's going to run an 8 pin rim and 20" Bar for awhile once it's complete until I sell it. (date to be determined,  )

)

Hey MasterMech, If ya don't mind what did ya pay for the Stihl crankcase tools. I priced a set from my dealer and almost fell over. Almost $500.

.

.Actually, and you will call me crazy, that's the plan. MS261 and a MS441C-M.Well, then sell the 046 and get the lightweight (actually heavier with less power) 441.

Really wish Stihl would roll out Mtronic in more than one model. The Brits get the MS241 Mtronic, why can't we have it on the 261?

Really wish Stihl would roll out Mtronic in more than one model. The Brits get the MS241 Mtronic, why can't we have it on the 261?

I wouldn't mind having another hp or two on a 460 even with "just" an 18" bar. I have a 32" bar for mine and it struggles to cut wood with it. I like to be able to stick saw on wood and BZZZZ... through. No bogging or having to "work" the saw.

I don't expect it to be a hot saw, but close.

And no, it's not just my saw, I have cut with 2 other 460s and they all were the same power on the "butt dyno"

2 hrs @ 200

2 hrs @ 200 .

.Dude - I want that mill. {{drool}}

Oh - and nice job on the other stuff.

For my use, I would prefer manual, but I don't want to side track this thread.Yah, me too.

It's just an ancient Bridgeport we have at work. Nothing fancy, all manual feeds, needs a LOT of work to be considered precise.

Mine too.My wife would have my a** for cooking paint in the oven

That's at my "night job" (I work overnights). Bridgeport, a Kearny Trekker (sp?) vertical mill that makes the Bridgeport look like a toy and an old Pratt & Whitney model C lathe. A few other nice toys too, including a 10' shearNice Bridgeport , I worked on a small block for 1-2 weeks building a stroker motor with a bridgeport. Is that at the house or do you have a shop ??

, and an ancient Do-All vertical bandsaw with hydraulic table feed.

, and an ancient Do-All vertical bandsaw with hydraulic table feed. )

)

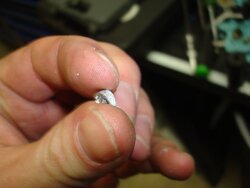

Disaster!

View attachment 92576

Uh Oh. Where did that come from?

I'll show you tomorrow after the camera recharges.

When I remounted the oil pump after that last photoshoot, I must've grabbed the wrong screw (too long). It punched a good hole in the wall of the crankcase instead of bottoming out.

If you need me, I'll be combing ebay for another case.

should be faster, tearing it down n puttin it back together, the second time around, it would be for me anyway

should be faster, tearing it down n puttin it back together, the second time around, it would be for me anywayAw man ! bummer

Good info in the threadshould be faster, tearing it down n puttin it back together, the second time around, it would be for me anyway