I'm new to pellet stoves and am wondering if, in the burn pot, should I be seeing mostly ash only or a build up of slag-like material? Sometimes it seems like there's a lot of non ash visible and it happens after around 14 hours of operation? My settings are 4-3-1 and the top are either 3 or 4 with one above for the blower.

Burn Pot Pile Up?

- Thread starter BillM2

- Start date

-

Active since 1995, Hearth.com is THE place on the internet for free information and advice about wood stoves, pellet stoves and other energy saving equipment.

We strive to provide opinions, articles, discussions and history related to Hearth Products and in a more general sense, energy issues.

We promote the EFFICIENT, RESPONSIBLE, CLEAN and SAFE use of all fuels, whether renewable or fossil.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

- Status

- Not open for further replies.

HEMI

Feeling the Heat

Heaterhunter

Member

I'm using a Englander 25 PDVC and Hamer's Hot Ones (all oak). Exterior, thru the wall, 3" inch with one tee and one elbow to the vent rising 8' or so. Also have OAK installed.

tsmith

Minister of Fire

I am burning Hamers in my Quad AE this year and am also having problems with huge clinker formations in the burn pot. Try a different pellet and see if it changes, I believe from what I am hearing on here about htis problem, hamer had a bad batch of pellets this year.

SmokeyTheBear

Minister of Fire

Clinkers are a PITA, if you have full control of both your feed rate and air. You can deal with this if not you have to just clean out the clinkers periodically.

That stove has a bit of adjustment available.

More air will eject more of the ash.

Less fuel will create less ash.

The goal is to have enough air to eject almost all of the created ash.

Yes this fouls up the usual burn pattern for your stove.

or

Burn a pellet that produces less ash or lighter ash.

That stove has a bit of adjustment available.

More air will eject more of the ash.

Less fuel will create less ash.

The goal is to have enough air to eject almost all of the created ash.

Yes this fouls up the usual burn pattern for your stove.

or

Burn a pellet that produces less ash or lighter ash.

SmokeyTheBear

Minister of Fire

BillM2 said:I'm using a Englander 25 PDVC and Hamer's Hot Ones (all oak). Exterior, thru the wall, 3" inch with one tee and one elbow to the vent rising 8' or so. Also have OAK installed.

You might want to check that venting you have there against what England says is the maximum for 3" pipe.

The tee and I'm assuming 90 degree elbow is an EVL of 10, the 8 foot rise is an EVL of 4 totaling 14 now, if you have 2 feet of horizontal to get outside with you have an EVL of 16.

But that aside, bad gaskets, and/or a dirty stove and/or vent system and/or vent system out of specifications can make a mess of the critical air flow need to help keep the burn pot area clean of ash.

I think your EVL calculation is about right -- but what the heck is EVL and how does it impact my set-up? This is a brand new unit, about 3 weeks old and is cleaned daily.

I

imacman

Guest

Bill, first of all, you don't have enough air for the stove to burn w/o clinkers forming. Try 4-5-1, or 4-6-1.

As for EVL, it stands for Equivalent Vent Length. Most stove manufacturers recommend switching to 4" pipe if the EVL goes much past 15, or if you're at high altitude.

1' vertical pipe = evl of .5

1' of horiz. pipe = " " 1

90 degree elbow or cleanout T = 5

45 " " = 2.5

As for EVL, it stands for Equivalent Vent Length. Most stove manufacturers recommend switching to 4" pipe if the EVL goes much past 15, or if you're at high altitude.

1' vertical pipe = evl of .5

1' of horiz. pipe = " " 1

90 degree elbow or cleanout T = 5

45 " " = 2.5

This may or may not be related, but I'm still getting the vibration or rumble, gusty winds or not. Seems if there's a hot, high fire, it'll rumble more. But it will also do it at low heat and low fan speeds. Would the EVL calculation of 16 be part of the problem for both these ongoing issues? I suppose I could lose a foot or so off the vertical rise. I'm getting good heat otherwise. Here's a diagram (dashes equal 1'length): STOVE - - T - - - - - - - - Elbow (90), cap. I've noticed the glass gets dirty within four hours of operating.

I'll also try the settings suggested and see if there's an improvement.

Thanks!

I'll also try the settings suggested and see if there's an improvement.

Thanks!

Pgoodii

New Member

The comment on hammers would make sense the hammers I bought during the summer I was fine, but when I started on the ton I bought in December is when I started having large clinker formations. I posted on here and someone suggested opening the draft on my stove and running a wire up the ash traps, I have done both and it helped but I am still getting some build up in the burn pot after about 24 hours. I may pick up some stove chow at lowes and just see if there is a difference. I will let you guys know if it does.

I

imacman

Guest

Bill,

Mike Holton from Englander had a post a while back about the rumbling....don't know if you saw it.

He found that if you remove the OAK from the back of the stove, and cover about 1/4 to 1/3 of the intake w/ foil tape, it helps.

Take a look at post #6 by Mike in this thread.....it might help:

www.hearth.com/econtent/index.php/forums/viewthread/66782/#763148

Mike Holton from Englander had a post a while back about the rumbling....don't know if you saw it.

He found that if you remove the OAK from the back of the stove, and cover about 1/4 to 1/3 of the intake w/ foil tape, it helps.

Take a look at post #6 by Mike in this thread.....it might help:

www.hearth.com/econtent/index.php/forums/viewthread/66782/#763148

Yes, that's on the list to try. Mike's suggestion sounds, sound. Will post my results once determined.

We're looking at single digit temps tonight with light NW wind. So far, so good. Downstairs where the stove is located it's 70 degrees, upstairs 67. Not too shabby (accept for those pesty clinkers and rumbling ghosts)!

We're looking at single digit temps tonight with light NW wind. So far, so good. Downstairs where the stove is located it's 70 degrees, upstairs 67. Not too shabby (accept for those pesty clinkers and rumbling ghosts)!

SmokeyTheBear

Minister of Fire

Would taking four feet out of your vertical cause a problem with where the termination would fall?

And by any chance are you venting into the prevailing wind where you are?

Could you post a picture of the outside venting.

And by any chance are you venting into the prevailing wind where you are?

Could you post a picture of the outside venting.

Heaterhunter

Member

imacman said:Bill,

Mike Holton from Englander had a post a while back about the rumbling....don't know if you saw it.

He found that if you remove the OAK from the back of the stove, and cover about 1/4 to 1/3 of the intake w/ foil tape, it helps.

Take a look at post #6 by Mike in this thread.....it might help:

www.hearth.com/econtent/index.php/forums/viewthread/66782/#763148

+1. I removed the OAK from my stove 4 years ago, didn't cover the intake with any tape, just left it wide open and the stove has been running much better since as long as I'm burning good pellets. I've been told you need to be carful with this in a new tight-built house. My stove is in the basement and their are too many places to get air down their!

SmokeyTheBear

Minister of Fire

Heaterhunter said:imacman said:Bill,

Mike Holton from Englander had a post a while back about the rumbling....don't know if you saw it.

He found that if you remove the OAK from the back of the stove, and cover about 1/4 to 1/3 of the intake w/ foil tape, it helps.

Take a look at post #6 by Mike in this thread.....it might help:

www.hearth.com/econtent/index.php/forums/viewthread/66782/#763148

+1. I removed the OAK from my stove 4 years ago, didn't cover the intake with any tape, just left it wide open and the stove has been running much better since as long as I'm burning good pellets. I've been told you need to be carful with this in a new tight-built house. My stove is in the basement and their are too many places to get air down their!

You might want to check your manual Heaterhunter, it is likely an OAK is mandatory for your stove.

Heaterhunter

Member

Won't that reduce the combustion air into the stove? If burn pot build up is the issue wouldn't it make sense to maximize combustion air to clear ash more effectively? Please upgrade me if my thought process is wrong, it wouldn't be the first time %-P

Issue #1 -- Rumble: I spoke with Mike at Englander about the rumble and it's pretty certain the cause is how much air is being taken in. So, I've covered the air intake with foil heat tape, and it does have an effect. I do need to, however, cover more than the suggested 1/3 to 1/4 amount. It's more like half. I'll give it some time and report back whether or not this solved the problem. Mike mentioned if the glass got dark and sooty, then to open up the intake. It may take some time to find the "sweet spot" this unit likes. I may rig up a shutter to adjust intake air according to my heat settings, which I understand can impact the amount and frequency of this rumble.

Mike doesn't think the 8' rise or my EVL has any impact on the rumble.

Issue#2 -- Clinkers: By raising the LBA a notch to 4 or 5, clinker formation with the Hamer's (all oak) is less pronounced.

This morning the temp was -2 at 6am -- we had clear skies overhead in this part of the state. I had the stove set at 3 and 5 overnight (ate a lot of pellets) and the house stayed in the mid 60s pretty much. My furnace did kick on a bit which I expected -- we live in a 100 year old house with lots of windows and not enough insulation. Temp at this writing climbing, now 9 degrees, and stove alone at 5 and 6 keeping the downstairs at 68. There's a slight breeze. Given it's some 60 degrees colder outdoors, not too bad.

Mike doesn't think the 8' rise or my EVL has any impact on the rumble.

Issue#2 -- Clinkers: By raising the LBA a notch to 4 or 5, clinker formation with the Hamer's (all oak) is less pronounced.

This morning the temp was -2 at 6am -- we had clear skies overhead in this part of the state. I had the stove set at 3 and 5 overnight (ate a lot of pellets) and the house stayed in the mid 60s pretty much. My furnace did kick on a bit which I expected -- we live in a 100 year old house with lots of windows and not enough insulation. Temp at this writing climbing, now 9 degrees, and stove alone at 5 and 6 keeping the downstairs at 68. There's a slight breeze. Given it's some 60 degrees colder outdoors, not too bad.

SmokeyTheBear

Minister of Fire

This may surprise you BillM2, but my suggestion on the venting was not directed at curing the rumble, but the entire burn issue, and it just might calm that rumble as well as the stoves ability to move air through the system will definitely be changed.

Thanks Smokey -- yes, I understood. I included the venting aspect as a possible factor for rumbling. I'm now into an hour or so of restricting the intake and with a higher air number, and the rumbling is less frequent and intense and the burn pot appears to be burning better with less build-up of a clinker pile.

SmokeyTheBear

Minister of Fire

Heaterhunter said:Won't that reduce the combustion air into the stove? If burn pot build up is the issue wouldn't it make sense to maximize combustion air to clear ash more effectively? Please upgrade me if my thought process is wrong, it wouldn't be the first time %-P

Yes it will impact the combustion air the stove has access to, however it is likely there is more air than the stove actually needs even at the increased LBA settings.

What it effectively does is change the resonant frequencies of the air column and the entire vent system.

Sort of like tuning a pipe organ.

antmorin

New Member

Same problem. I have an Englander PDV. Bought it used last year. Worked great last year feeder rate 4 air blower 5 nice and toasty. This year if I put the feeder rate to 4 the pellets just pile up in the burn pot some turn black and then fall into the ash pan I have to remove them every couple of hours when I'm home. I have put the feeder rate to 3 and still have to clear out the pot every 4 to 5 hours. I've kept it very clean, I clean out the burn pot and ash collection area every 5 bags. Cleaned out the vents twice in the last 2 weeks and I'm positive its clean from outside to the combustion blower I can see everything is spotless. It is in the basement and I do not have the air intake hooked up to the outside. I remove the impingement plate and clean behind there. Same venting as last year. Burning Barefoots. The manual doesn't help on where to clean.

From everything I've read here it seems that I have an air flow problem but I can't find where.

I think that there may be a hidden area that I don't know about to clean out it seems to be getting worse. Does anyone know?

Maybe the air combustion motor? How do I tell if it's slowing down?

I don't think there is an air intake adjustment?

From everything I've read here it seems that I have an air flow problem but I can't find where.

I think that there may be a hidden area that I don't know about to clean out it seems to be getting worse. Does anyone know?

Maybe the air combustion motor? How do I tell if it's slowing down?

I don't think there is an air intake adjustment?

forya

Member

I am getting the same problem with Hamers and my Harman accentra. I was thinking of calling my dealer out to adjust my combustion fan speed as there is no way to do this manually. but maybe I will just try to keep up with pulling down the ash by hand. The heat is great with these pellets. I do notice that when I wake up that there are a lot of half burnt pellets that overflow the giant ash clump wall that forms from 8 straight hours of burn.

buildingmaint

Feeling the Heat

My Hammers are from Agway and I 'm having the same problem , have to dig a chunk out of my stove 4-6 times a day. First ton was fine but the last two tons have been clinker city.

I

imacman

Guest

burnit said:.....Worked great last year .....This year if I put the feeder rate to 4 the pellets just pile up in the burn pot .......From everything I've read here it seems that I have an air flow problem but I can't find where........Maybe the air combustion motor?.......

Yes, there is an airflow problem, especially since you say the stove ran great last year. This is a new year, and more ash has built-up.

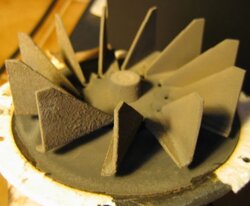

The combustion blower should be removed and cleaned, AT LEAST after each heating season, and for sure after about 2 tons. NOTE: GET REPLACEMENT GASKET BEFORE DOING THIS

There is an access panel on the left side of the stove (facing it). Unplug stove, remove plate, disconnect motor power wires, remove 6 nuts holding the motor to the plenum box. Remove motor & clean fan blades with wire brush, and scraper/putty knife under the vanes on the motor body.

Then, clean/vacuum inside the plenum....re-assemble motor w/ new gasket.

This is what my comb. blower and plenum box looked like after 58 bags:

Attachments

- Status

- Not open for further replies.

Similar threads

- Replies

- 2

- Views

- 271

- Replies

- 2

- Views

- 644

- Replies

- 3

- Views

- 387

- Replies

- 0

- Views

- 502